Method of co-filling a dairy product and co-filled composite dairy product

a dairy product and composite technology, applied in the field of dairy products, can solve the problems of low production efficiency in continuous filling process, high abrasion and frequent failure, and equipment necessary for rotating the nozzle needs to be accommodated in relatively little available space, so as to avoid the effect of technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

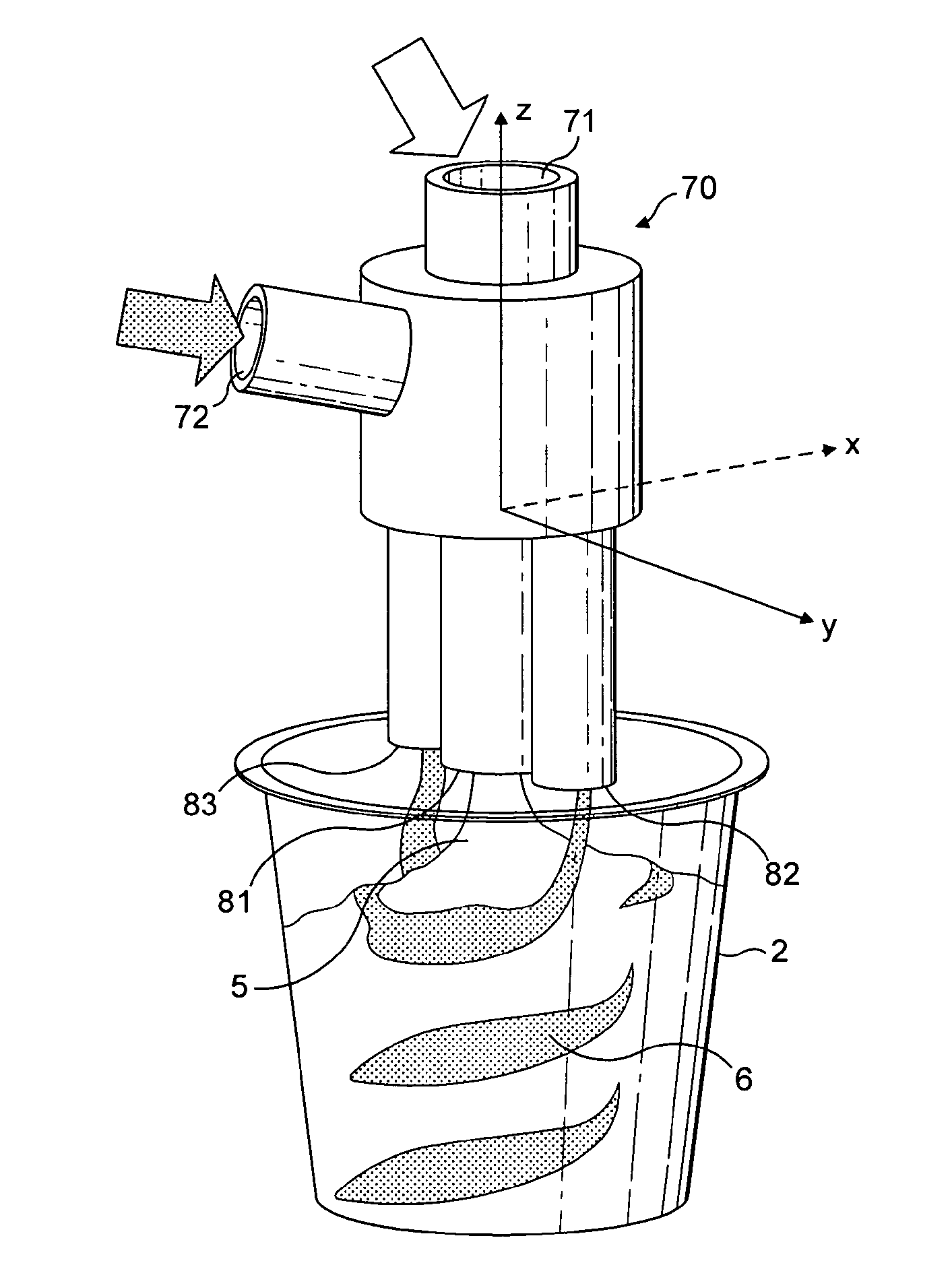

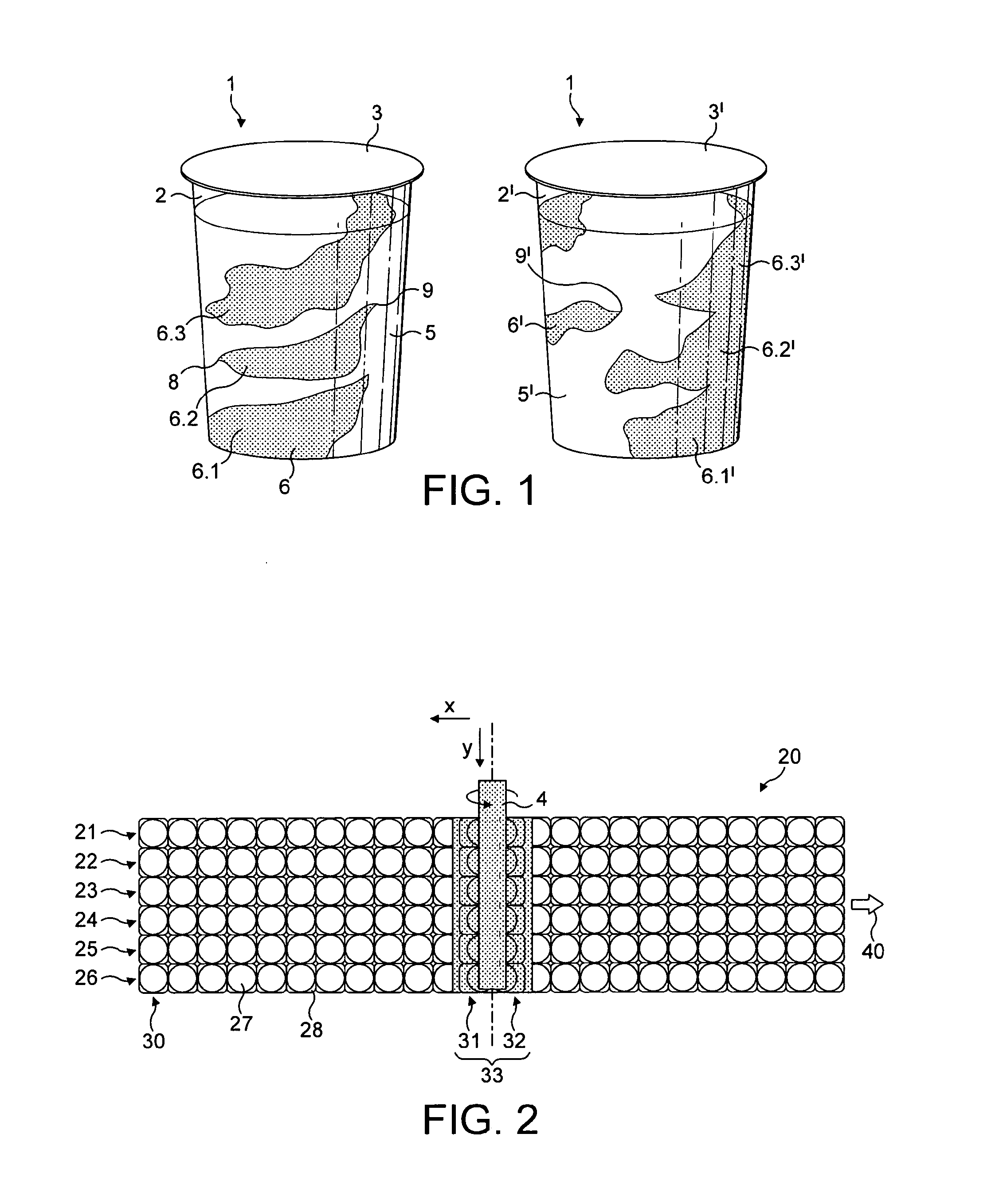

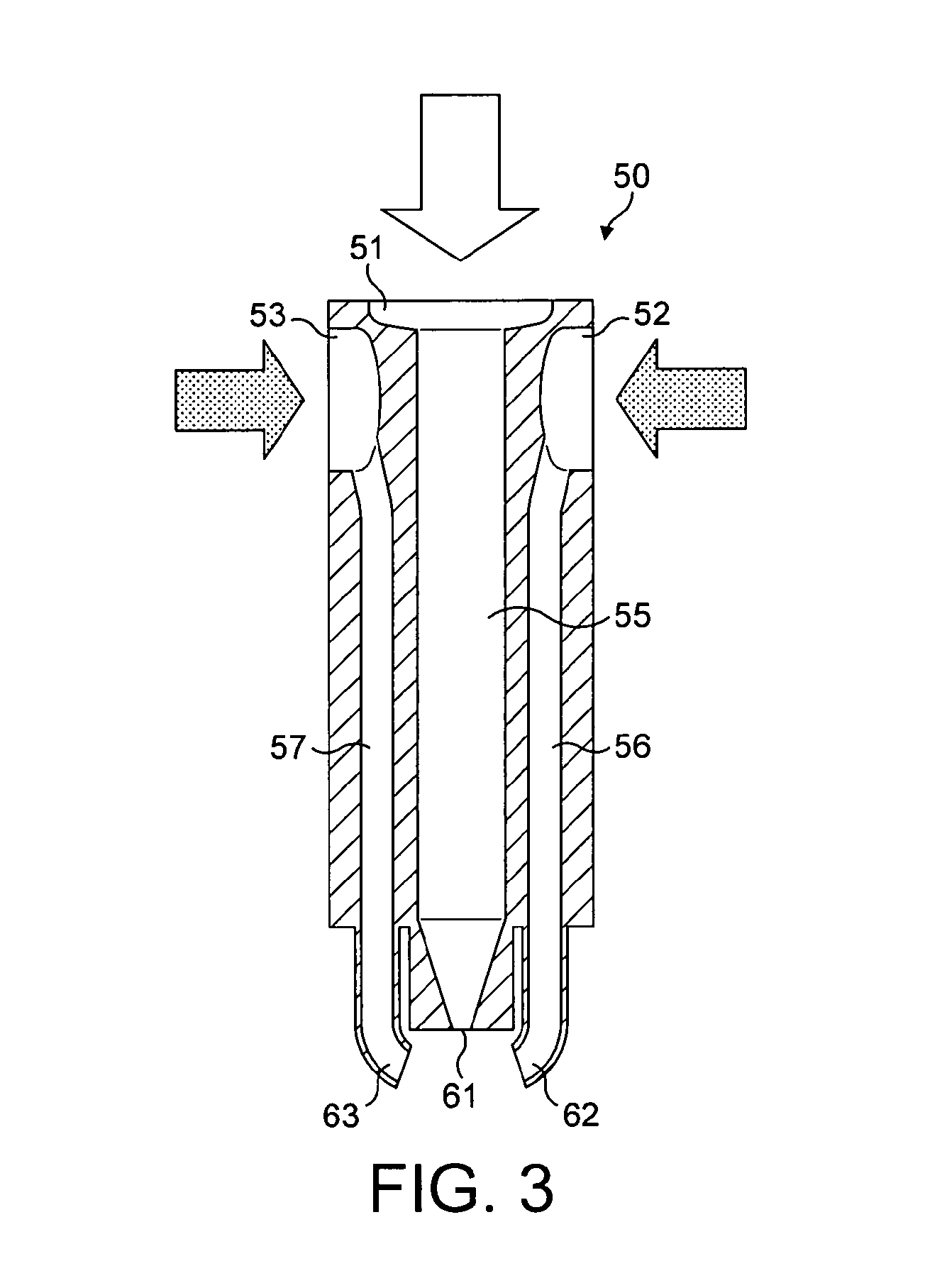

[0046]The present invention concerns a composite dairy product. A “composite dairy product”, for the purpose of the present invention, is a product comprising at least two different viscous components, wherein at least one of said viscous components is a dairy component.

[0047]A “viscous dairy component”, for the purpose of the present invention, is a viscous, edible matter having, as a substantial ingredient, one or more milk and / or milk derived ingredients and in particular milk fat and / or milk protein. In particular, a “viscous dairy component” preferably comprises one or more selected from milk fat, casein, and whey protein. In order to be a dairy product, the milk and / or milk derived ingredient provides at least 20%, preferably at least 30%, more preferably at least 40% and most preferably at least 50% by weight of the viscous dairy component.

[0048]The viscous dairy component may be a fermented milk product, for example a yoghurt or a fresh cheese. It may also be a flan base, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com