Faucet diverter device

a diverter and faucet technology, applied in water installations, thin material processing, construction, etc., can solve the problems of water outflow, reduced life time, and increased cost and volume, and achieve the effect of simple and intuitive operation methods, and reducing the number of switch handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

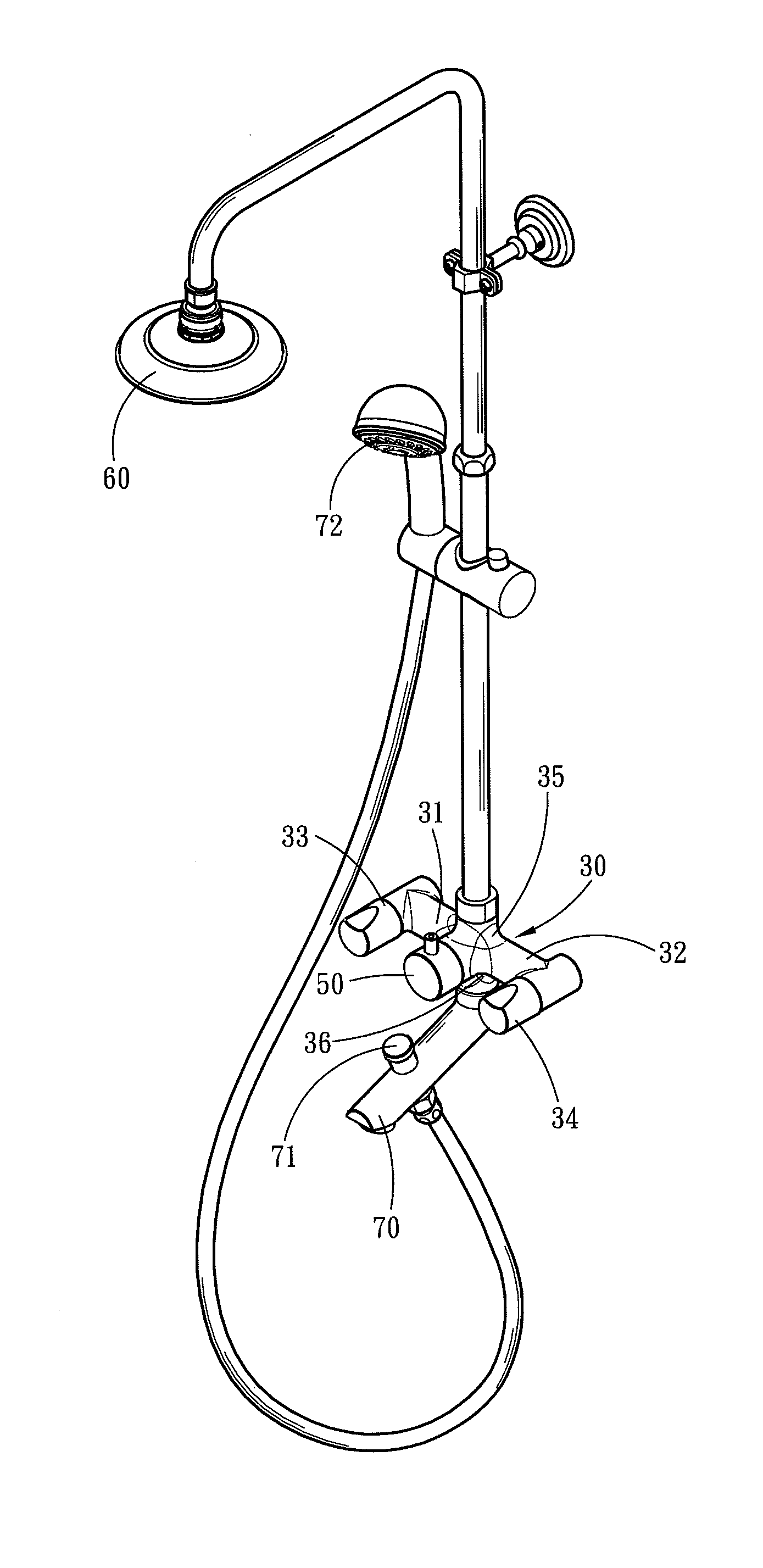

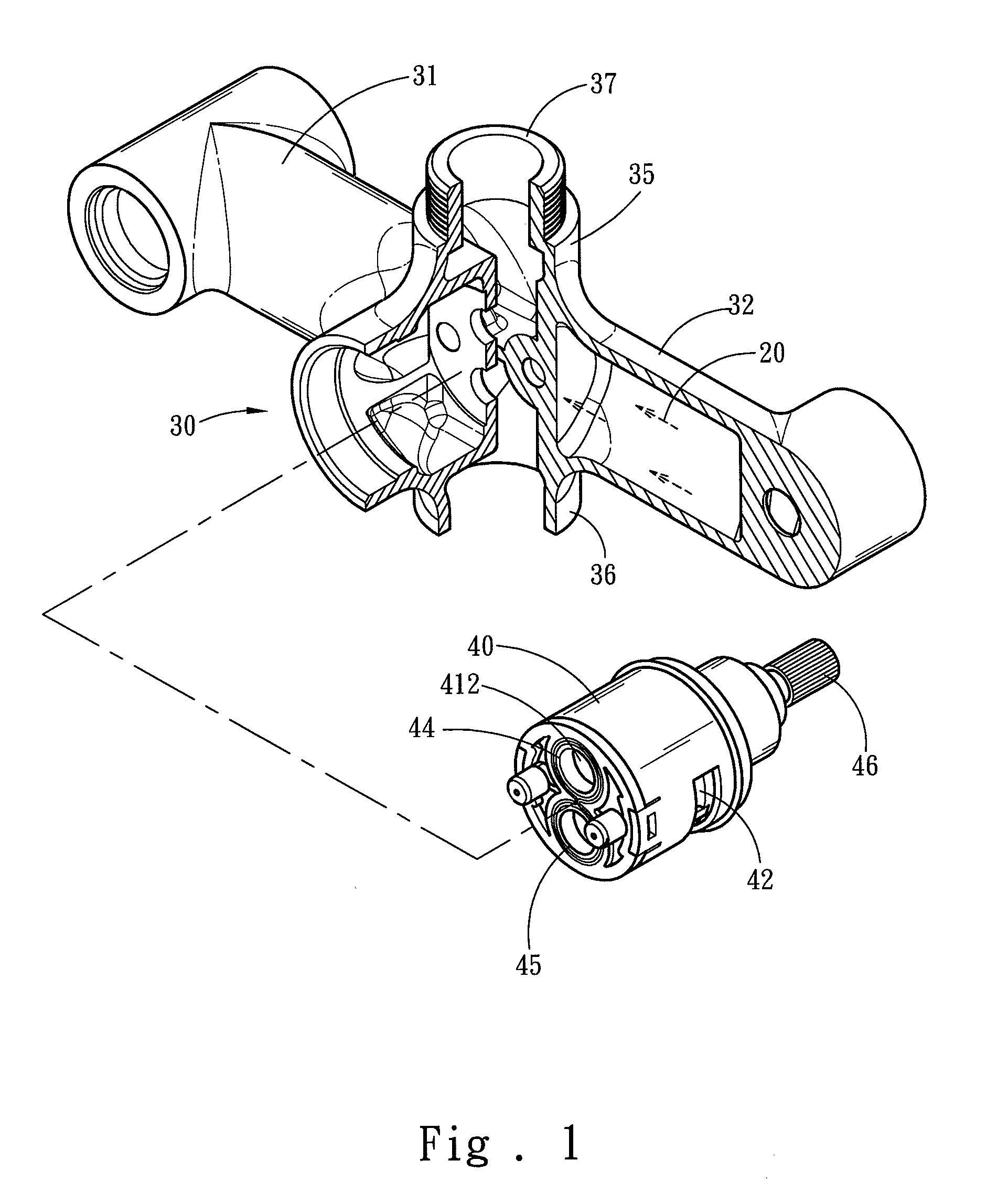

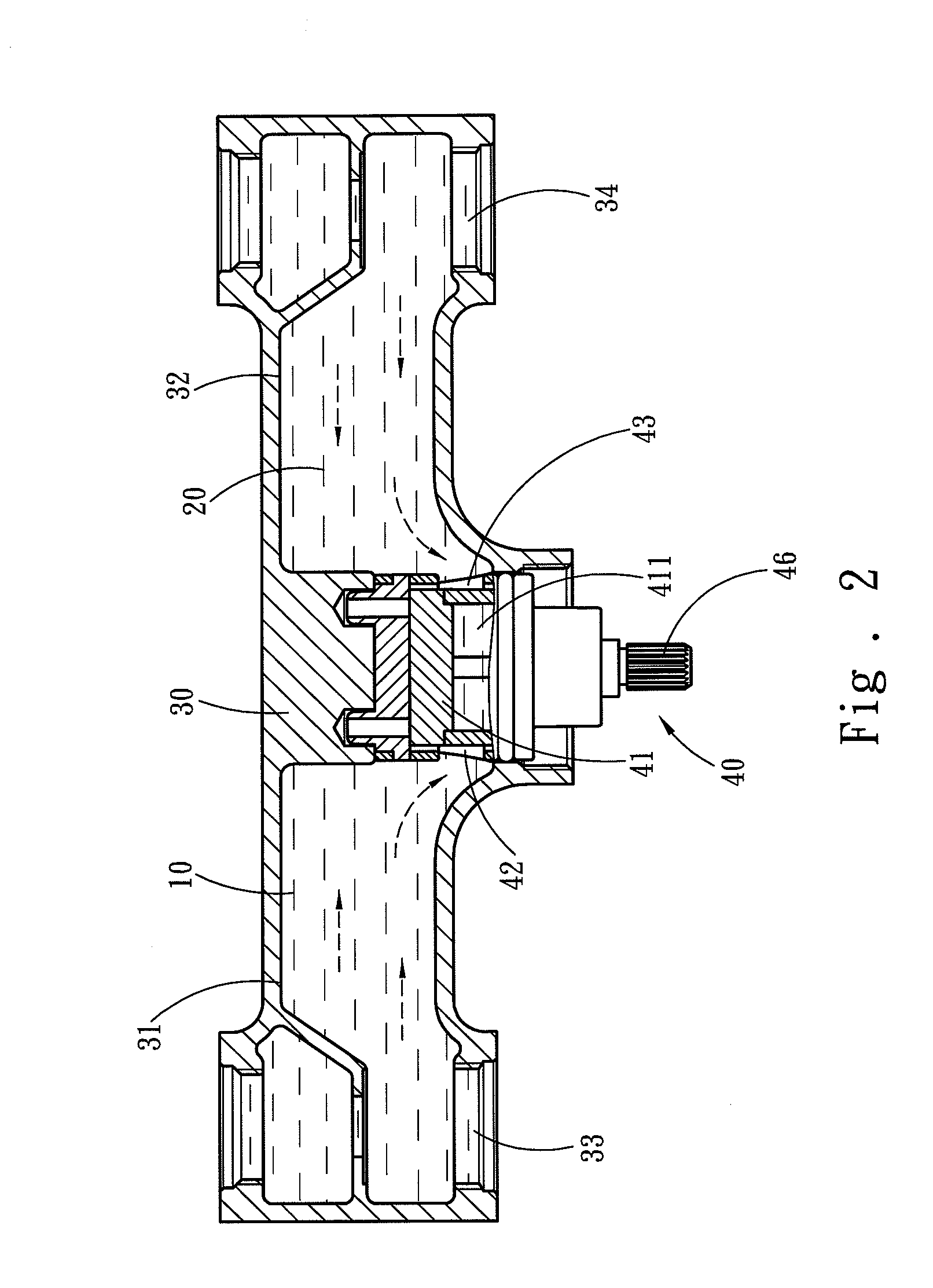

[0017]Please refer to FIG. 1, FIG. 2 and FIG. 3. As shown, the present invention is related to a faucet diverter device, including a faucet main body 30 and a diverter valve 40. The faucet main body 30 has a first channel 31 and a second channel 32 for respectively passing therethrough a first fluid 10 and a second fluid 20. The diverter valve 40, which is connected with the faucet main body 30, has a turning valve 41 thereinside, a first inlet 42 communicated with the first channel 31 and the turning valve 41, a second inlet 43 communicated with the second channel 32 and the turning valve 41, a first diverting outlet 44, a second diverting outlet 45 and a pivot 46 connected with the turning valve 41 for turning the turning valve 41. The first fluid 10 and the second fluid 20 respectively flow into the faucet main body 30 through the first channel 31 and the second channel 32, and respectively pass through the first inlet 42 and the second inlet 43 to enter the turning valve 41 insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com