Clean Viscosified Treatment Fluids and Associated Methods

a treatment fluid and viscosification technology, applied in the field of subterranean fluids, can solve the problems of reducing the rate at which the fluid is allowed to penetrate or leak off into desirable locations within the subterranean formation, affecting the rheology of the treatment fluid, and affecting the proportion of the fracturing fluid lost during the fracturing operation. , to achieve the effect of reducing the loss of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

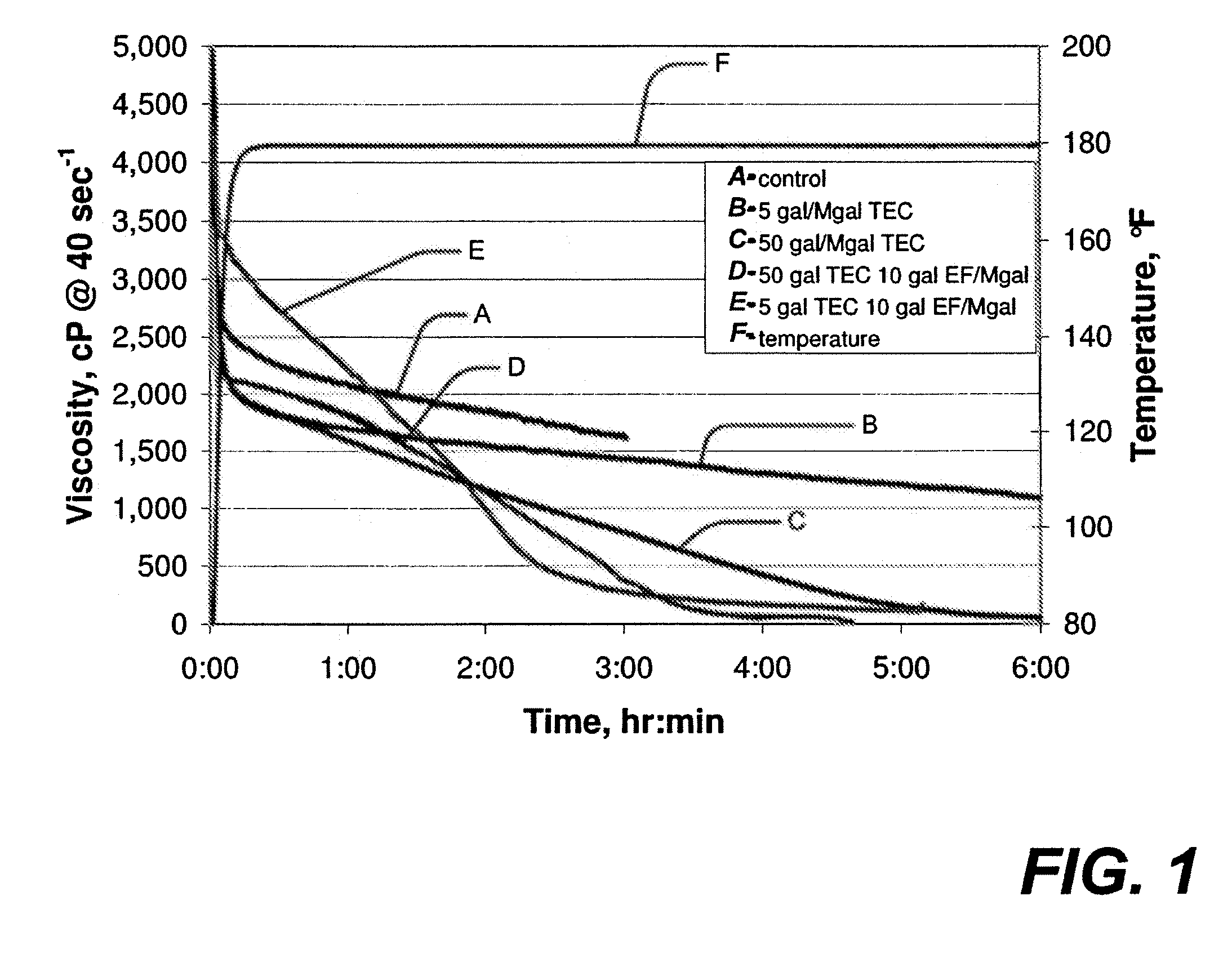

[0057]Initially the viscosity of a treatment fluid that did not contain a dual functional additive (such as either a triethyl citrate (TEC), ethyl formate (EF), amyl formate (AF), triacetin (TA), or diethyl malonate (DEM)) was obtained to provide a reference point for comparison. The samples were prepared by dissolving 1.080 g of Cekol 30000 in 150 g of tap water with shear in a small, glass blender jar. After hydrating for a minimum of 30 minutes, the esters were added at the concentrations as noted, followed by 1.4 ml (0.93% v / v) of aluminum crosslinker. All gels were strongly crosslinked upon addition of the crosslinker. Table 1 lists the prepared sample treatment fluids and their pH values.

TABLE 1Prepared Sample Treatment Fluids and pH ValuesEsterFluid initial pHnone4.57 5 gal / Mgal TEC4.1850 gal / Mgal TEC3.8050 gal / Mgal TEC + 10 gal / Mgal EF3.79 5 gal / Mgal TEC + 10 gal / Mgal EF4.37

[0058]Next, the viscosity of the treatment fluid above further containing 5 gal / Mgal of TEC and 50 gal...

example 2

[0059]Treatment fluids were prepared containing Aluminum-crosslinked 60 lb / Mgal CMC gel with one or more of the following dual-functional additives: TEC, amyl formate (AF), triacetin (TA), or diethyl malonate (DEM). For each fluid, the esters were present in the treatment fluid in the form of small droplets. Testing to determine final viscosity and pH was performed and the results show that each of the tested dual-functional additives (esters) used with this invention were capable of reducing the viscosity of the treatment fluid. As can be seen in Table 1, advantageous results were found using a combination of TEC and AF. In addition, TA also improved the viscosity break. DEM was sufficient to break the gel upon release of malonic acid. The results are shown in Table 2. The sample treatment fluids were prepared with the same polymer and crosslinker concentration as in example 1. All of the fluids initially were crosslinked gels. For the static break test procedure, the samples were ...

example 3

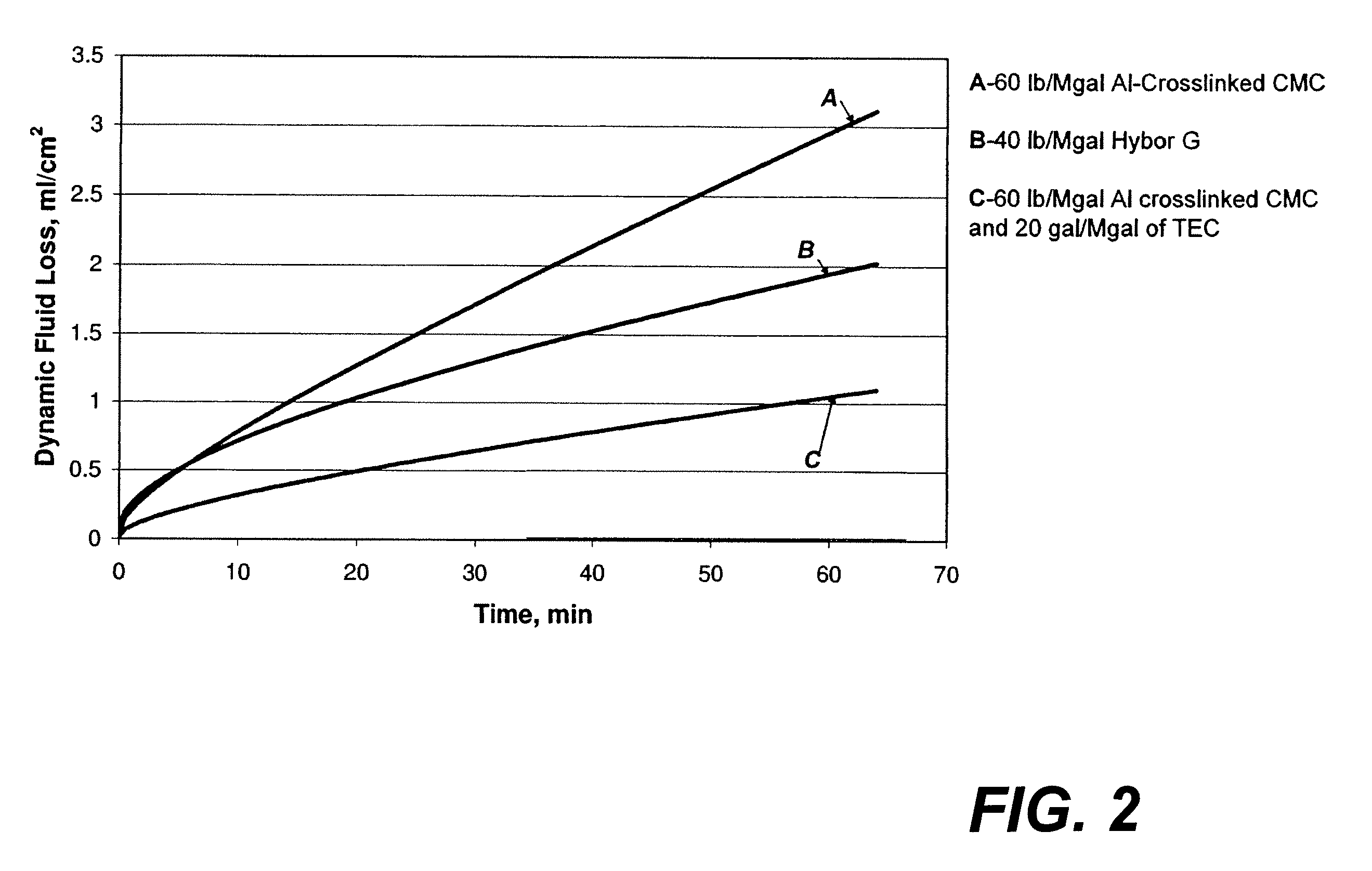

[0060]Treatment fluids containing 60 lb / Mgal Al-crosslinked CMC with and without TEC were prepared. In addition, treatment fluids containing 40 lb / Mgal Hybor G (a borate crosslinked guar available from Halliburton Energy Services, Inc. of Duncan, Okla.) were used as a comparison. The fluid loss properties of the treatment fluids were tested. FIG. 2 is a plot of dynamic fluid loss curves as a function of time for the treatment fluids and it shows that fluid loss was about half of that observed by the 40 lb / Mgal Hybor G treatment fluid. Thus, the dual functional additives of the present invention are capable of acting a fluid loss control agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com