System and method for controlling flow in a wellbore

a wellbore and flow control technology, applied in the direction of borehole/well accessories, thin material handling, construction, etc., can solve the problems of reducing affecting the flow rate of the wellbore, and subjecting the valve to substantial loading forces, so as to reduce the load force and reduce the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

In the following description, numerous details are set forth to provide an understanding of the present invention. However, it will be understood by those of ordinary skill in the art that the present invention may be practiced without these details and that numerous variations or modifications from the described embodiments may be possible.

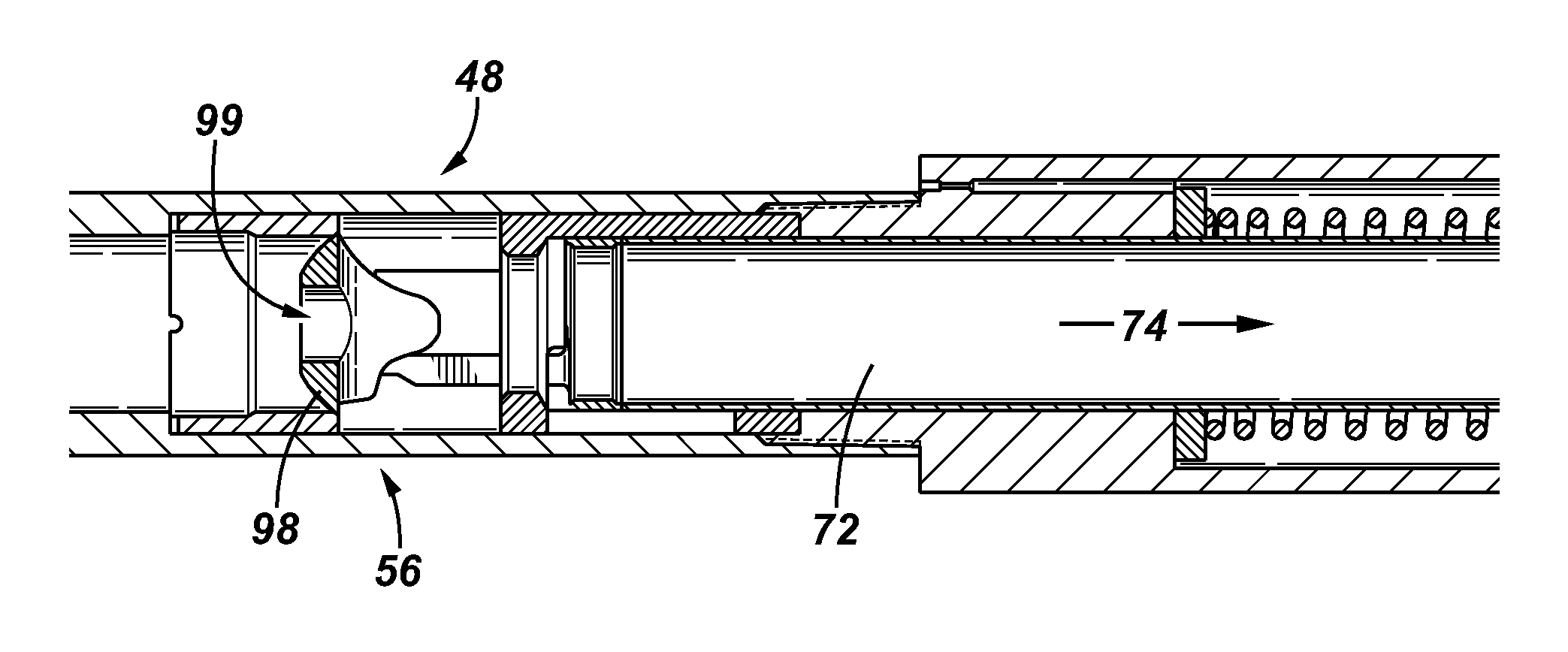

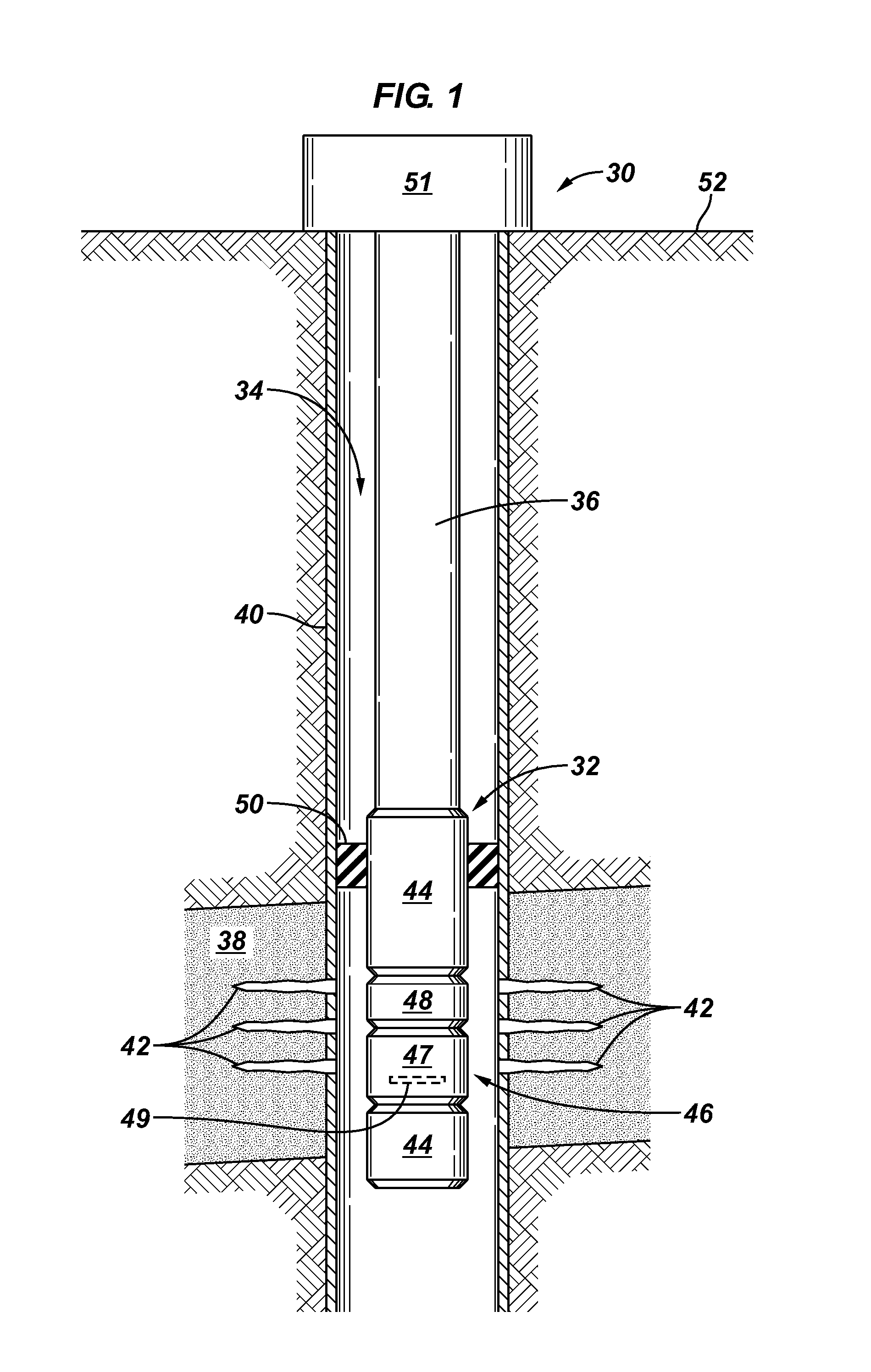

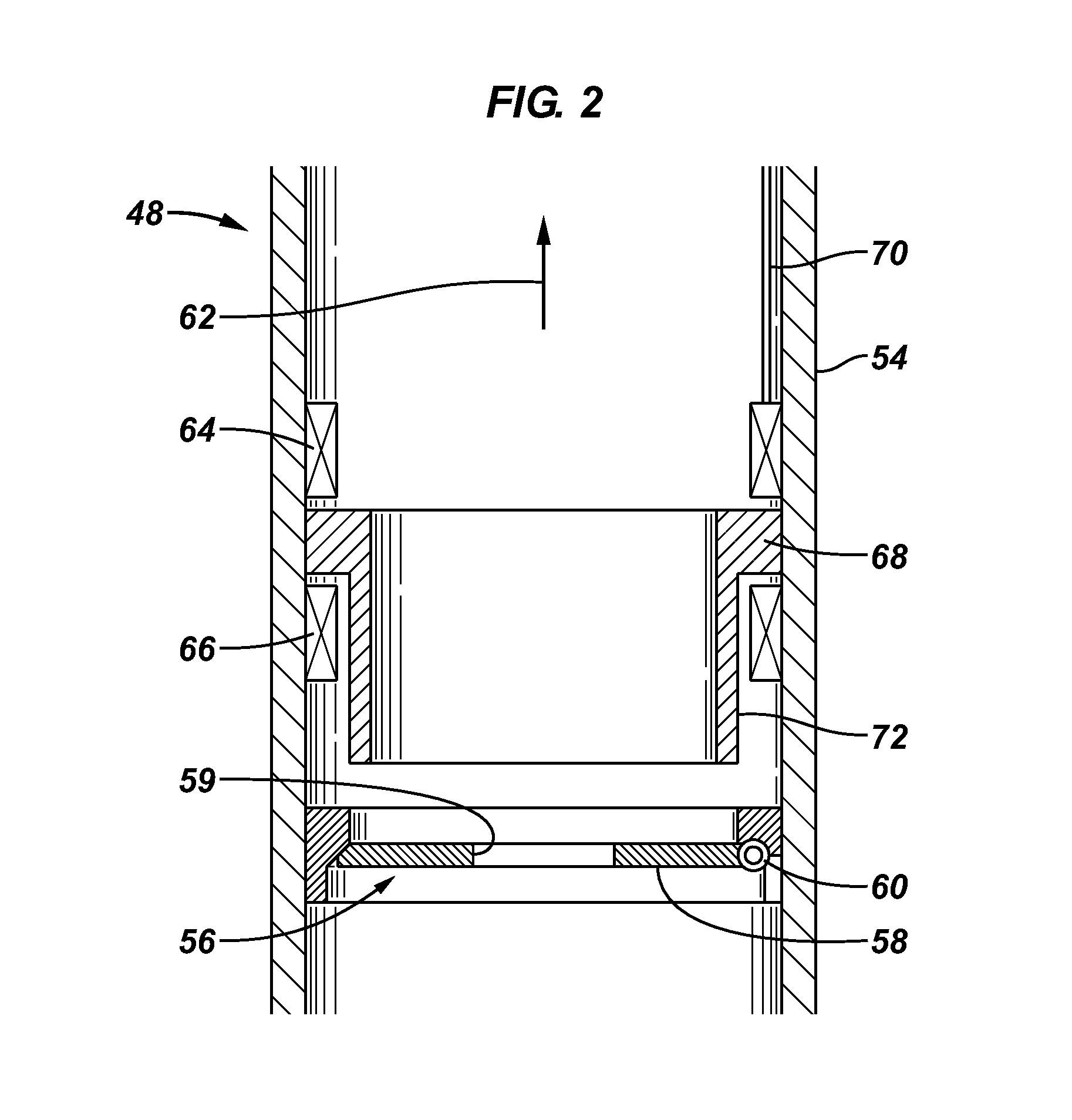

The present invention generally relates to a flow control system used to control flow in a wellbore. For example, the flow control system comprises a flow control device combined with a flow reduction mechanism for use in a variety of well related operations. The flow control system can be used in production and / or injection operations.

Generally, combining the flow restricting or flow reduction mechanism with the flow control device reduces potential loads acting on the flow control device which enhances the ability of the flow control device to close and seal effectively. In production applications, this allows higher production rates without ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com