Methods for corrosion control of steel in aqueous environment using passive iron-sulphur layers

a technology of passive ironsulphur and corrosion control, which is applied in the direction of solid-state diffusion coating, coating, chemistry apparatus and processes, etc., can solve the problems of severe corrosion to steel or iron parts, and the vulnerability of underground gas wells to such corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

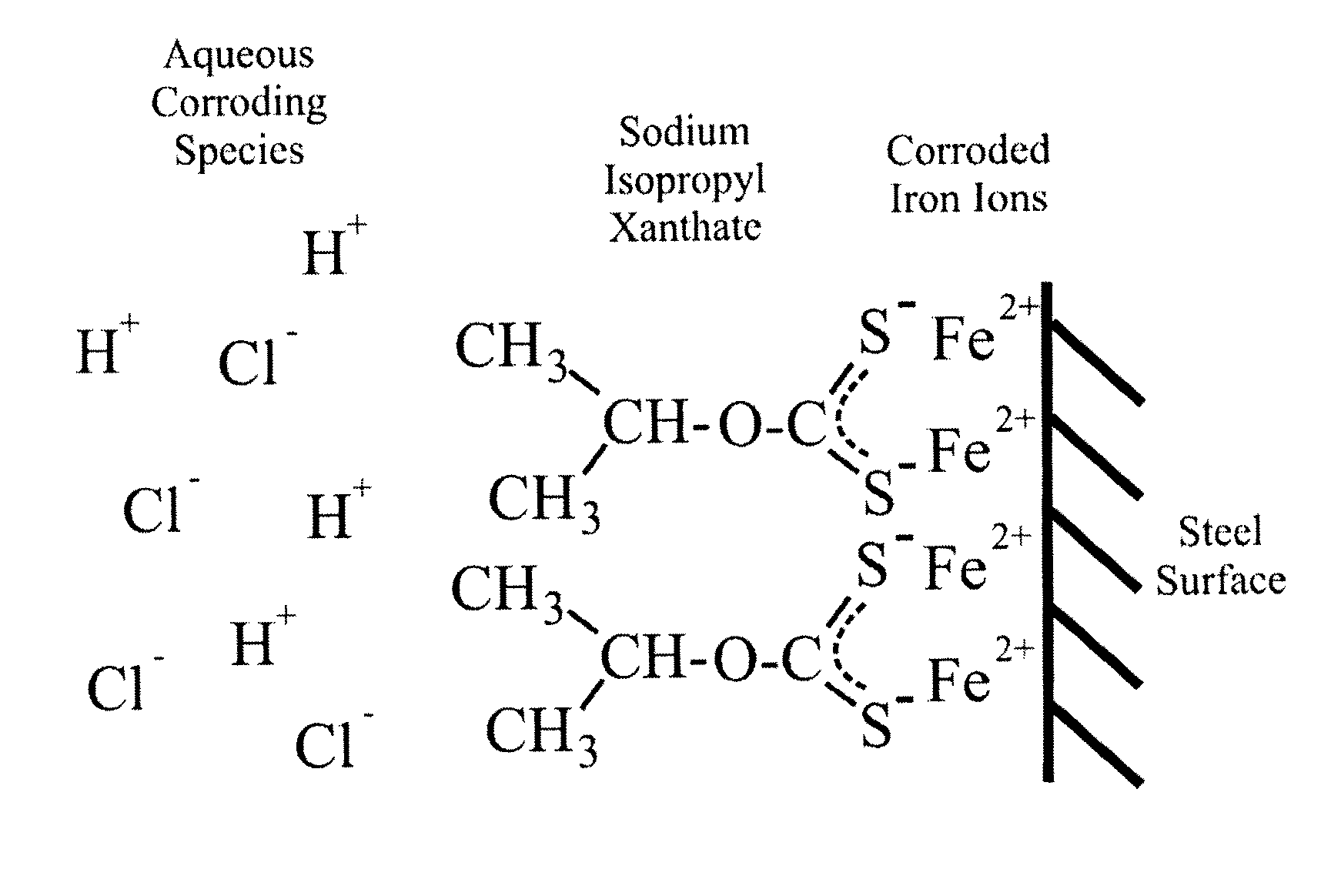

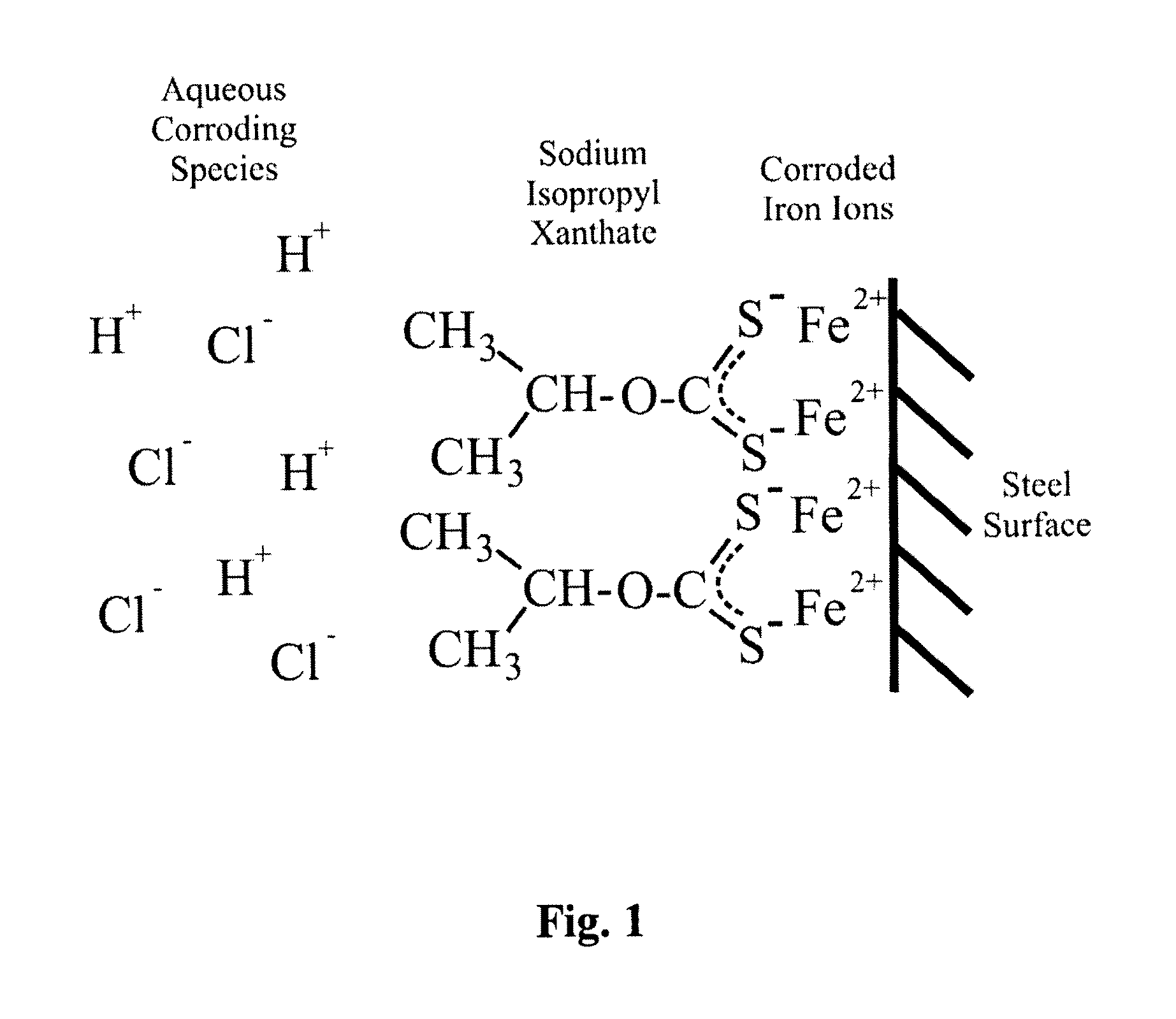

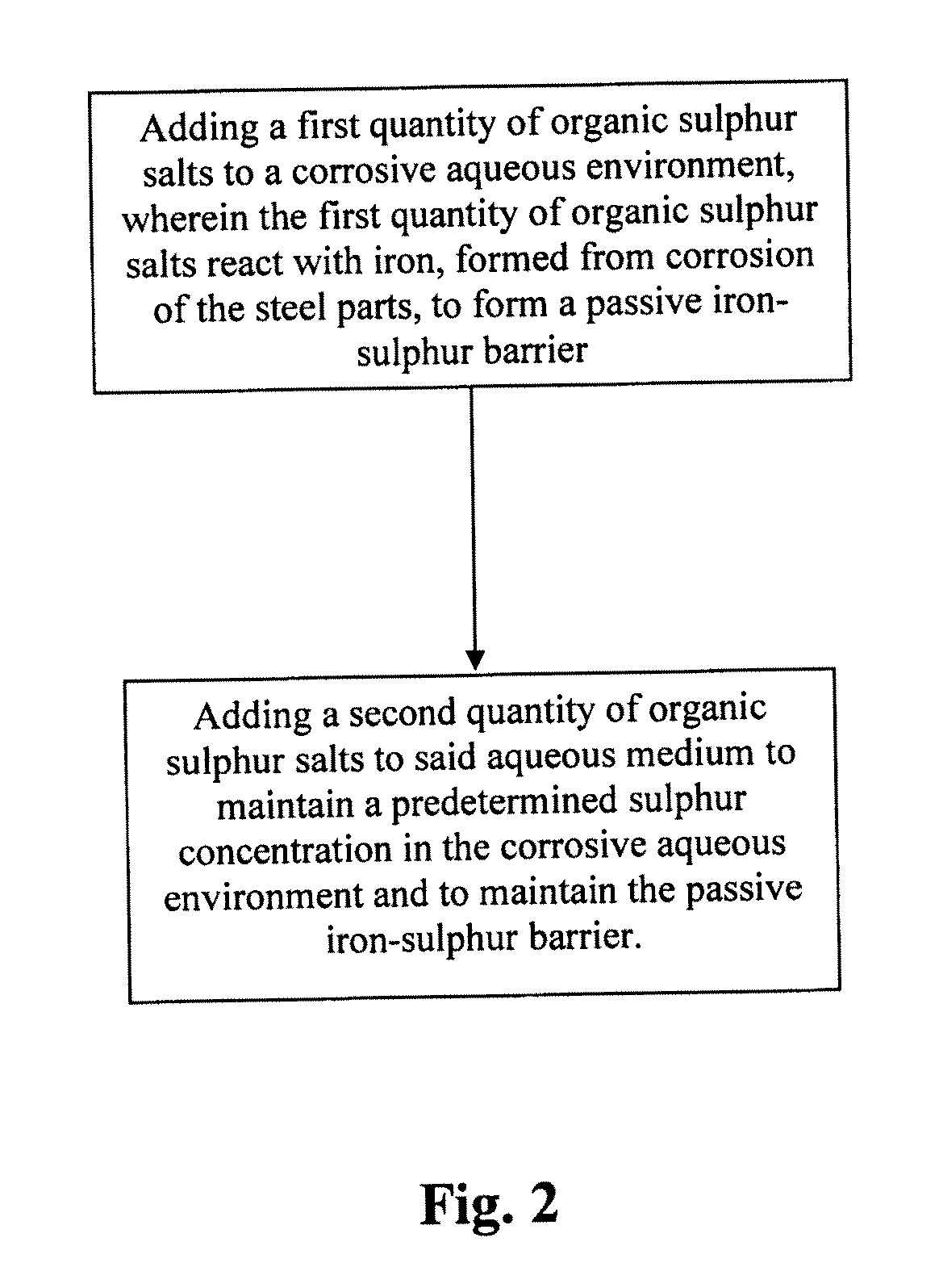

[0012]The present invention provides a novel approach to corrosion protection by creating a passive iron-sulphur barrier on the steel to protect it. The barrier is created by adding sulphur to the corrosive aqueous environment of the steel parts, which then reacts with exposed iron resulting from any initial corrosion to form a passive iron-sulphur barrier.

[0013]Solubility of the sulphur in the corrosive aqueous environment is important to allow for rapid forming of the passive iron-sulphur barrier. It is therefore important to find forms of sulphur that are safe, stable and quickly dissolvable in water. The present inventor has found that organic sulphur salts derived from carbon disulphide and thiophosphate salts are surprisingly effective forms of sulphur for the present application. For the purposes of the present invention, the phrase “organic sulphur salts” is used to describe and include all of the organic sulphur salts derived from carbon disulphide and thiophosphate salts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap