Special container for mobile extrusion equipment

a technology for mobile extrusion equipment and containers, applied in the field of containers, can solve the problems of high transportation costs, waste, extra connection work, etc., and achieve the effects of reducing some production and usage procedures, saving costs and processing time, and reducing unnecessary was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The following is a further description of the present invention with reference to the figures and the embodiments, but without a limitation to the present invention.

[0023]A preferred embodiment is as below:

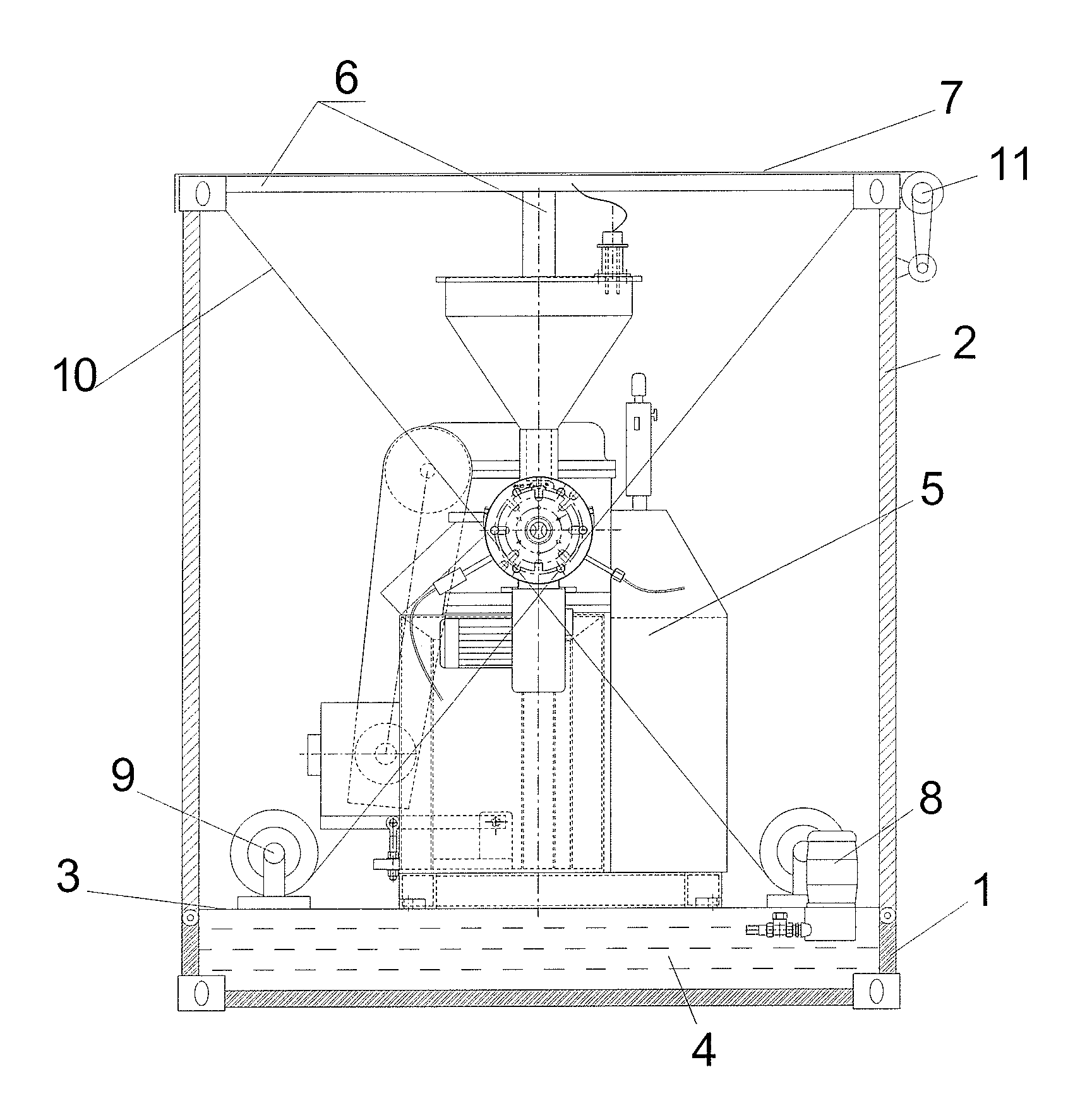

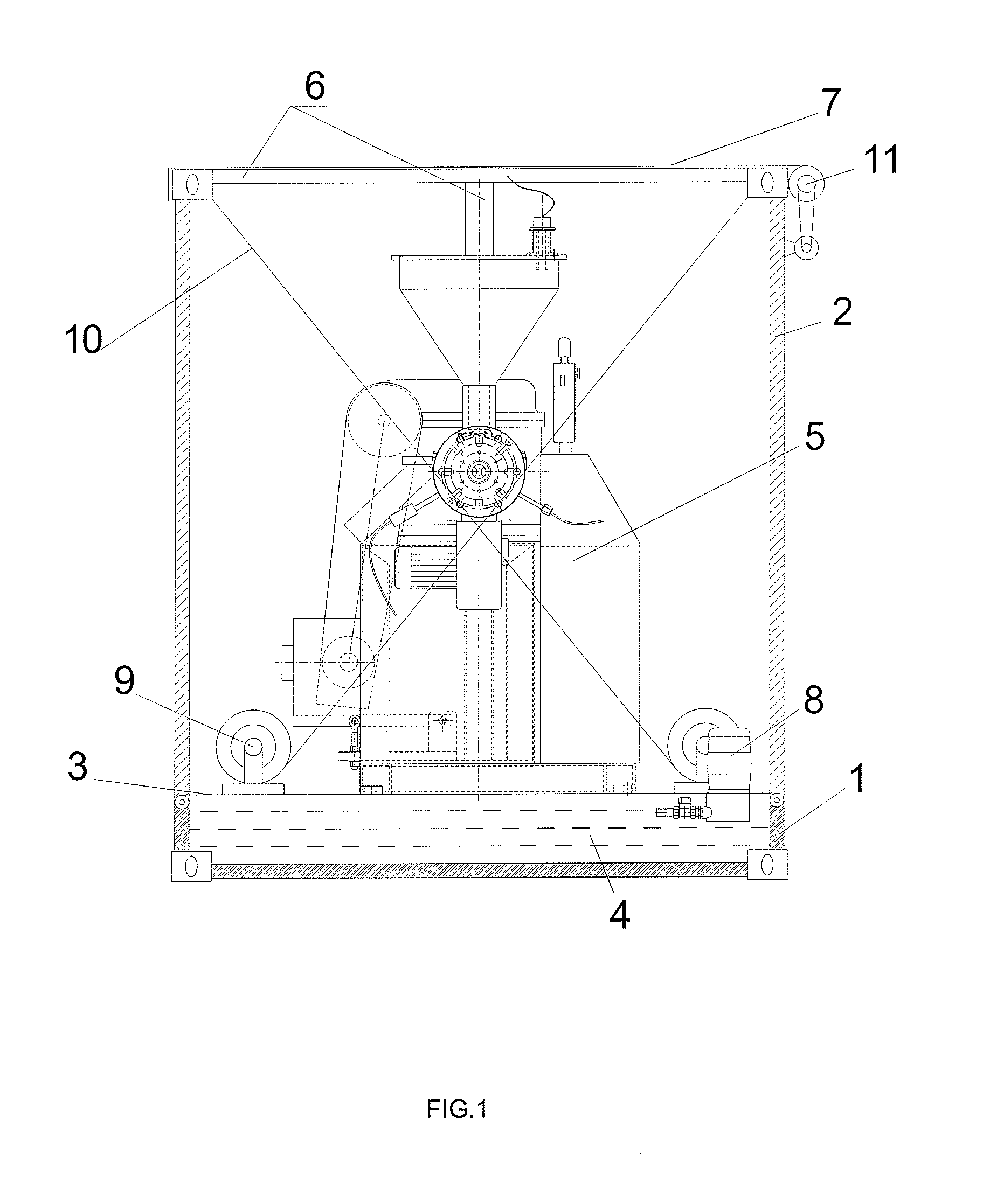

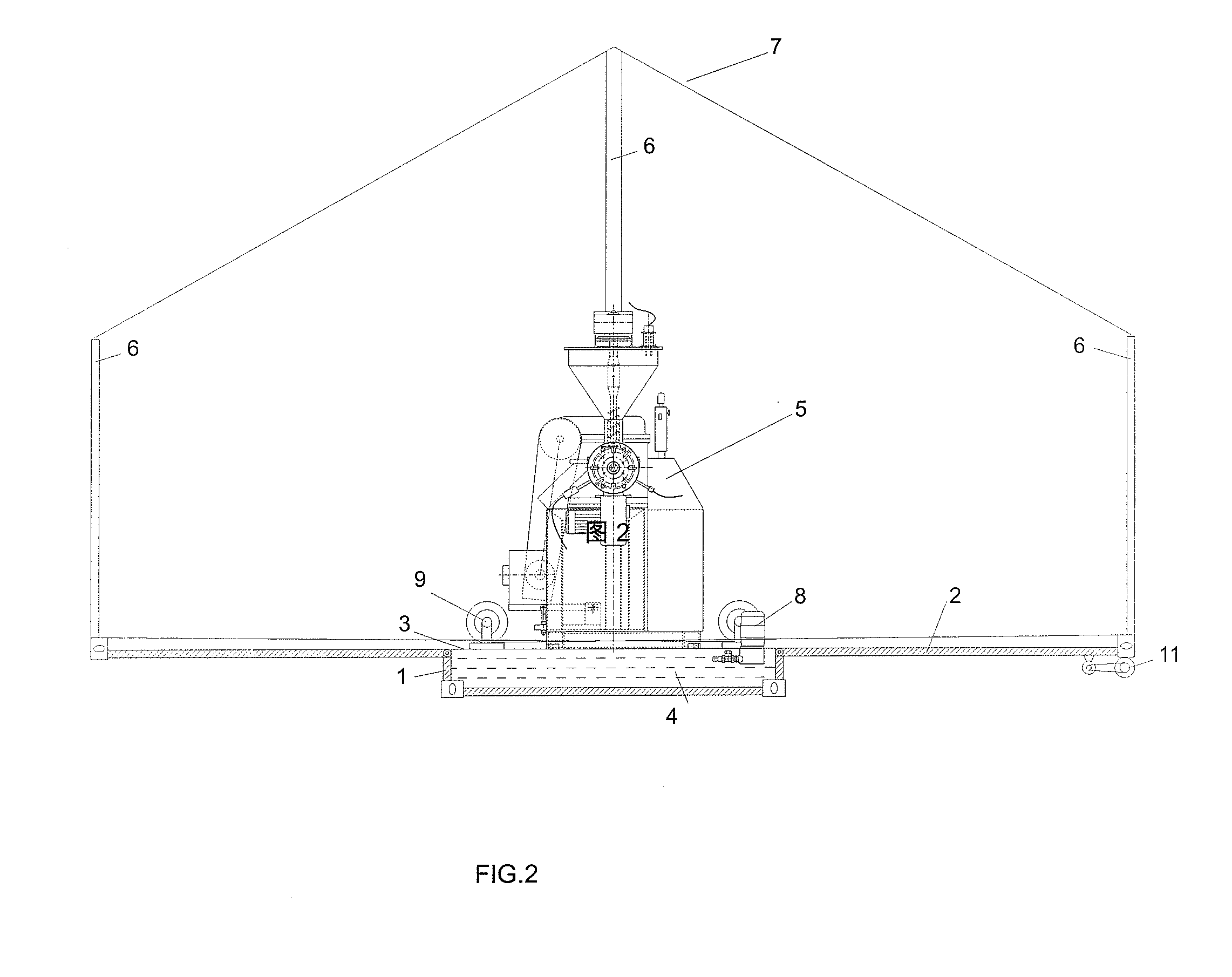

[0024]A special container for mobile extrusion equipment, comprising a case 1, the side plates 2 are articulated around the base 1, a floor 3 is set above the said base 1, a reservoir 4 is set under the floor 3, the extrusion equipment 5 is set above the floor 3, a simple holder 6 is set on the said side plates 2, and a piece of canvas 7 covers the simple holder 6.

[0025]A water pump 8 is set on the floor 3 above the reservoir 4.

[0026]A lifting windlass 9 is set above the floor 3, and the said lifting windlass 9 is connected to the top of the said side plates 2 through a steel wire rope 10.

[0027]The canvas 7 is connected to the canvas crimping machine 11 on the side plates 2.

[0028]The track 12 is set above the floor 3, and said extrusion equipment 5 is set above the said trac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com