Packaging system for a large article

a packaging system and large article technology, applied in the field of packaging systems, can solve the problems of increasing the cost and environmental impact of excessive packaging, increasing the weight of the product, and difficult to remove the product from the packaging, so as to overall packaging volume, and reduce the overall packaging weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

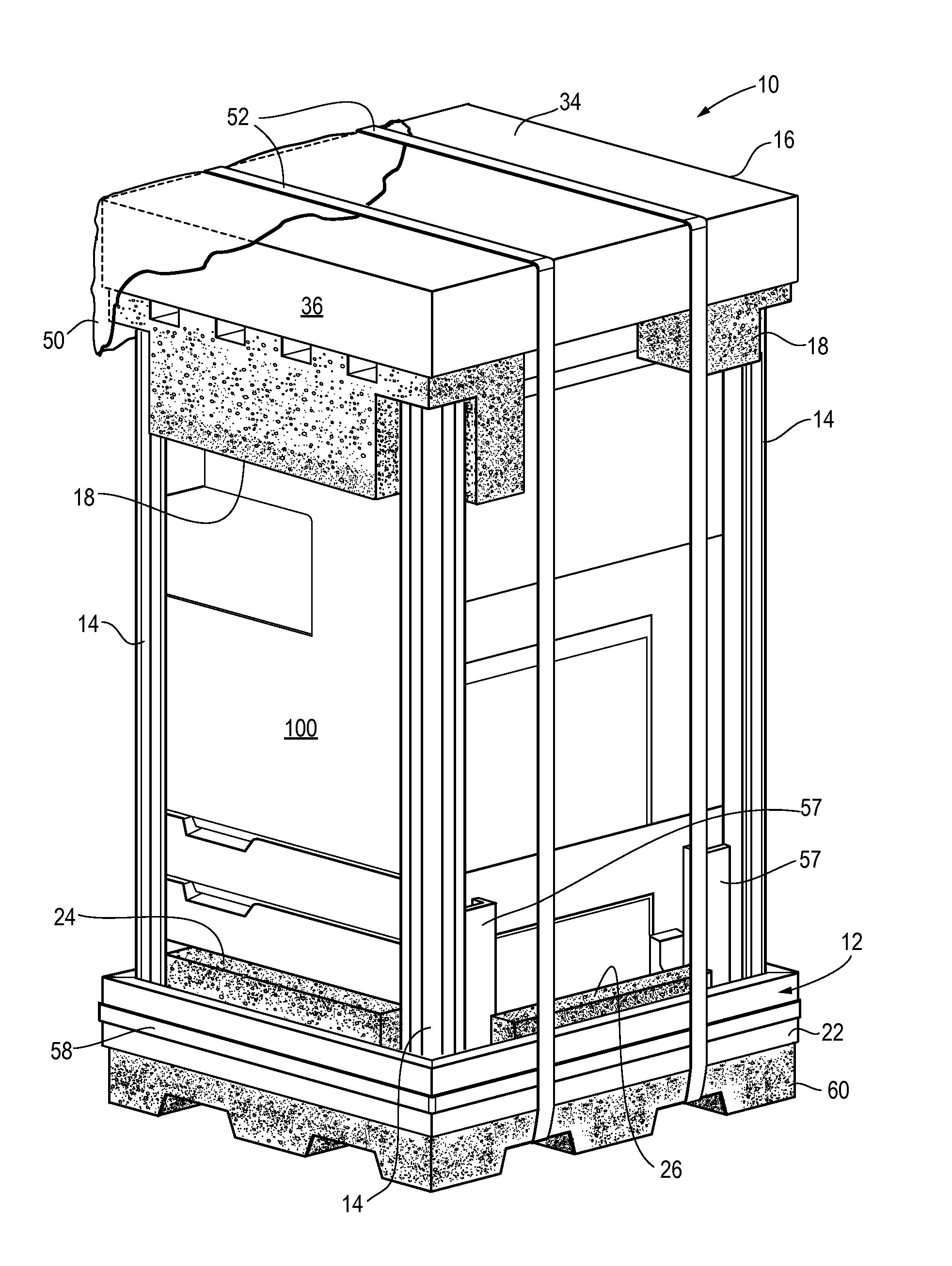

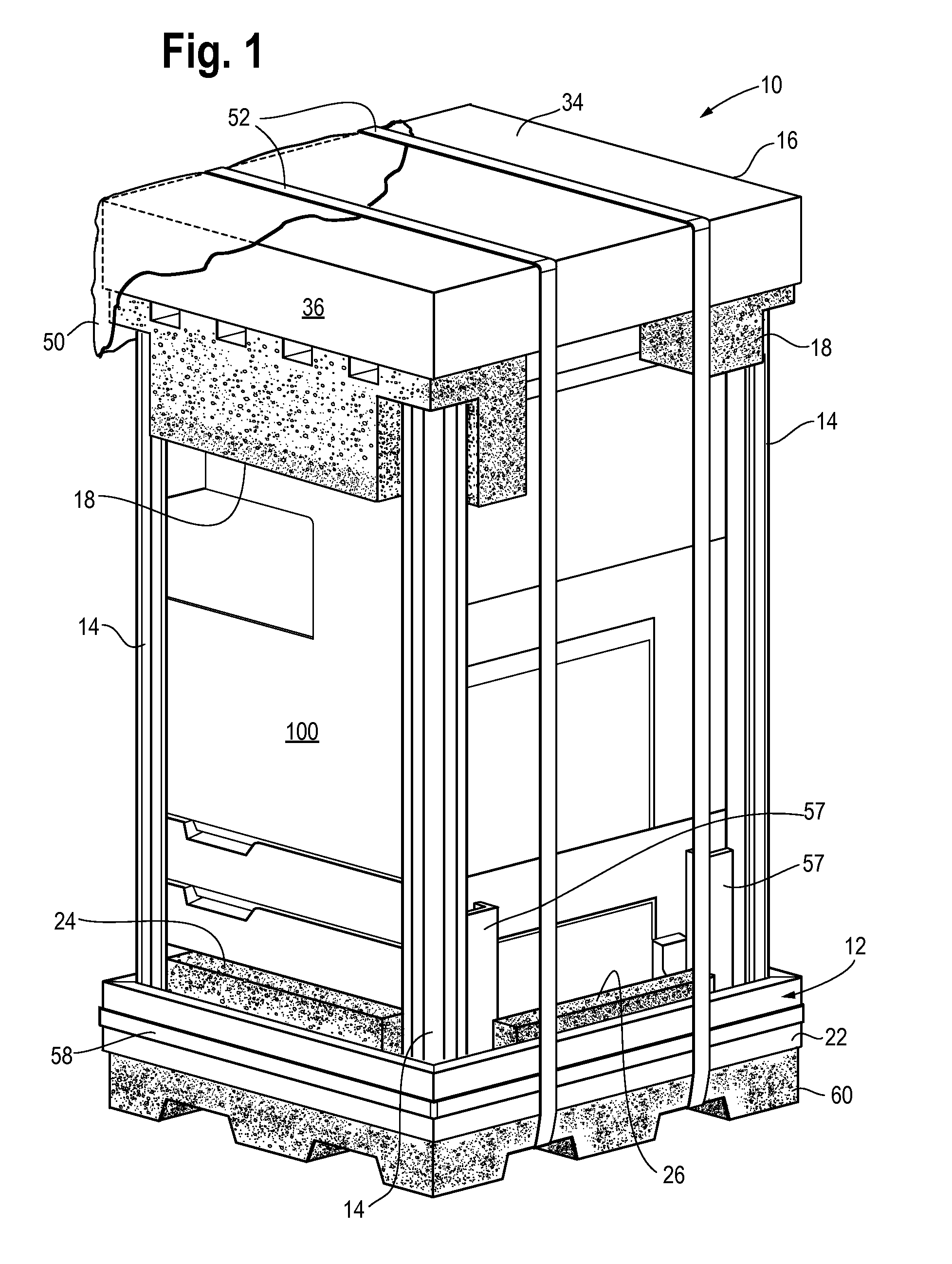

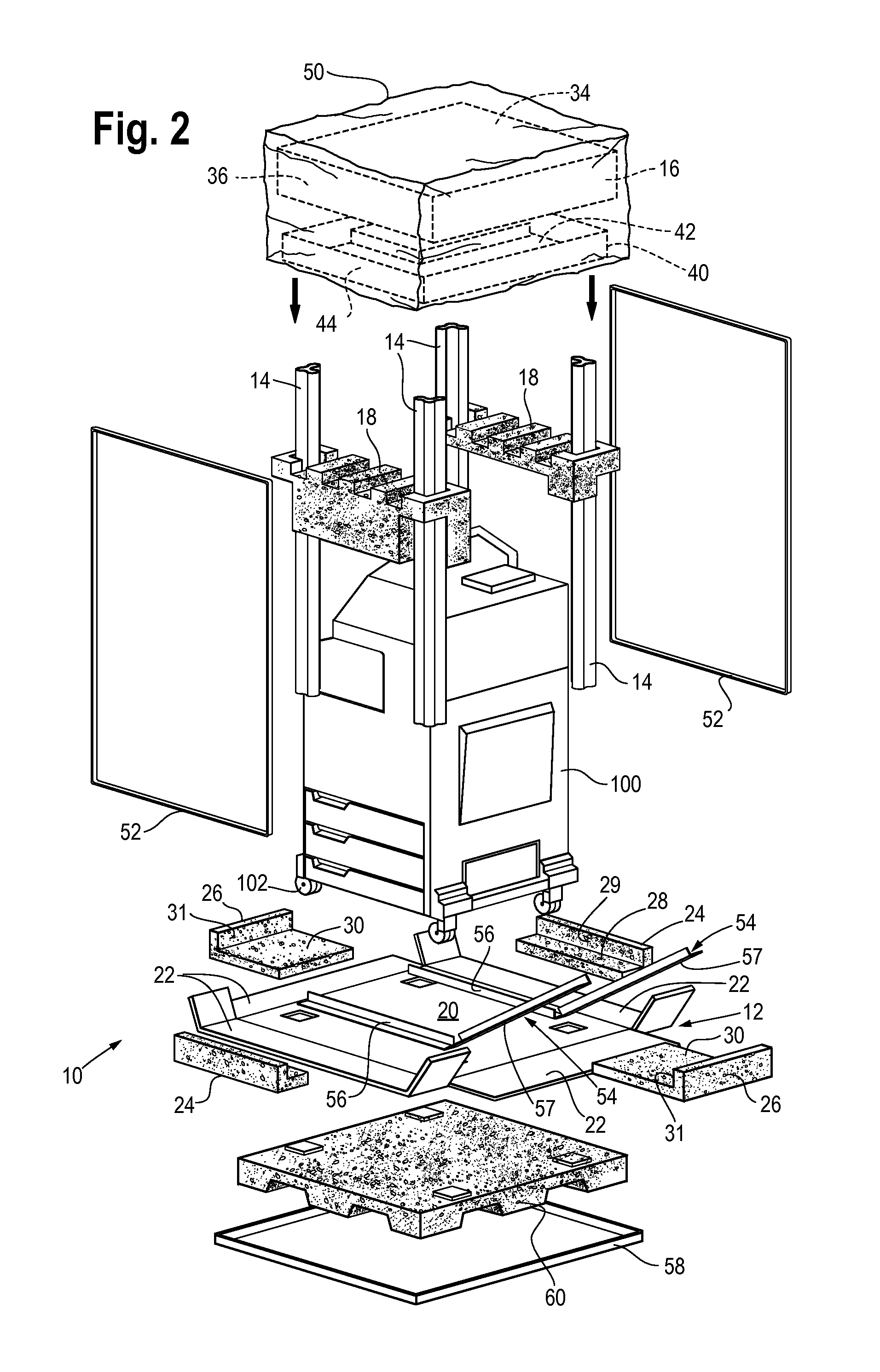

A second embodiment of the invention is shown in FIGS. 3-8. The packaging system 70 according to this second embodiment basically comprises a base tray 72, a foam base insert 74, corner posts 76, a top cap 80 and lower and upper foam braces. The base tray 72, corner posts 76 and top cap 80 may be made primarily of paper. The foam braces may be made from expanded polystyrene foam or other suitable cushioning material.

As in the first embodiment, the base tray 72 may be formed from a die cut, folded blank and comprises a substantially rectangular bottom panel 81 having a perimeter and upwardly extending side panels 82 hingedly affixed to the bottom panel 81 along its perimeter. The base tray 72 defines four corners for accommodating the corner posts 76.

The four corner posts 76 extend vertically from the bottom panel 81 to the top panel 104 of the top cap 80. As perhaps best shown in FIG. 4, each corner post 76 comprises an inner, article facing, wall 77 and a substantially coextensive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com