Method for treating surface of magnesium-based metal to give metallic texture thereof

a magnesium-based metal and surface treatment technology, applied in the direction of cell components, coatings, printing, etc., can solve the problems of irregular oxide film giving difficulty in realizing metallic texture, difficult to form transparent anodizing film,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, an embodiment of a method for treating a surface of magnesium-based metal will be described in detail with reference to the accompanying drawings. Throughout the drawings, like reference numerals are used to designate like elements.

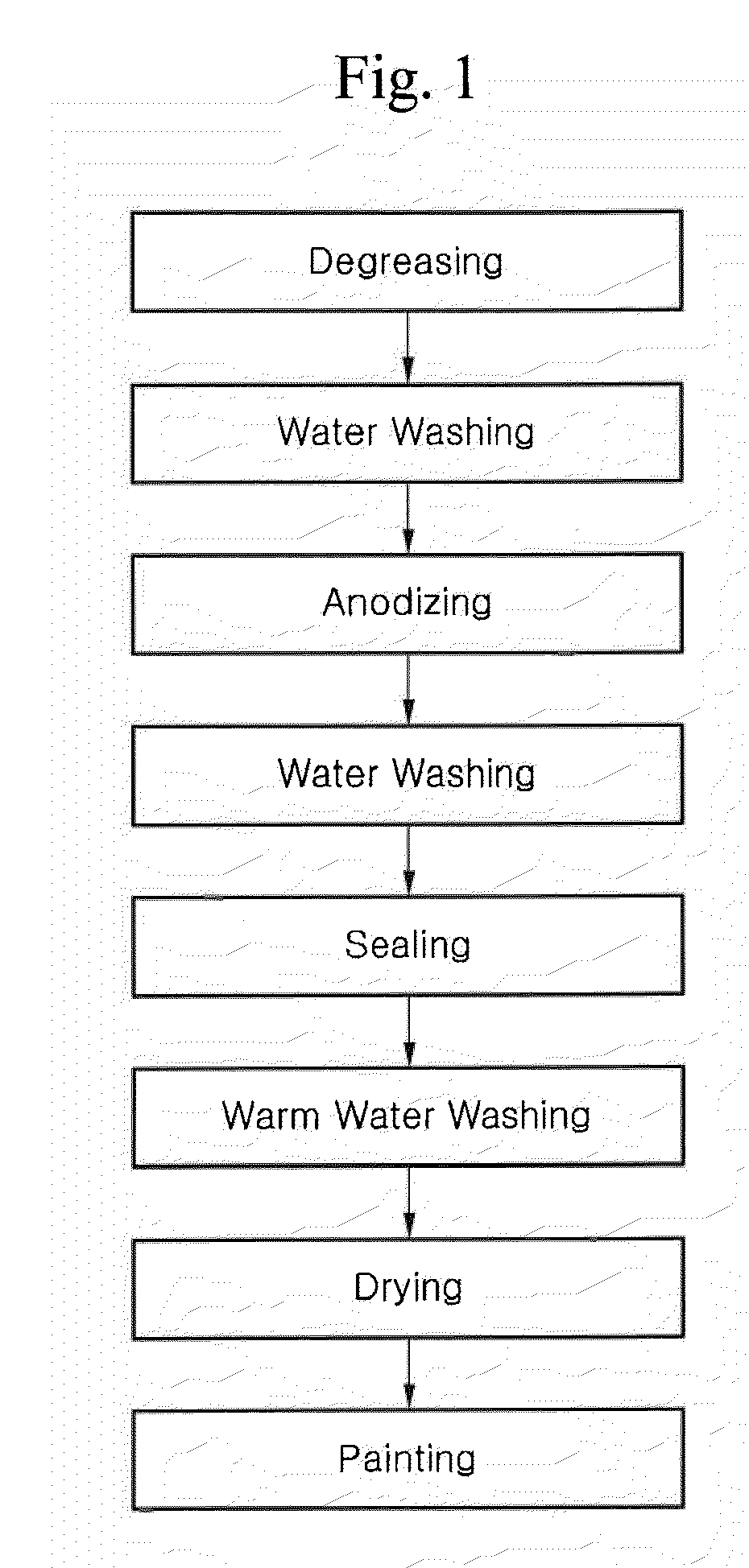

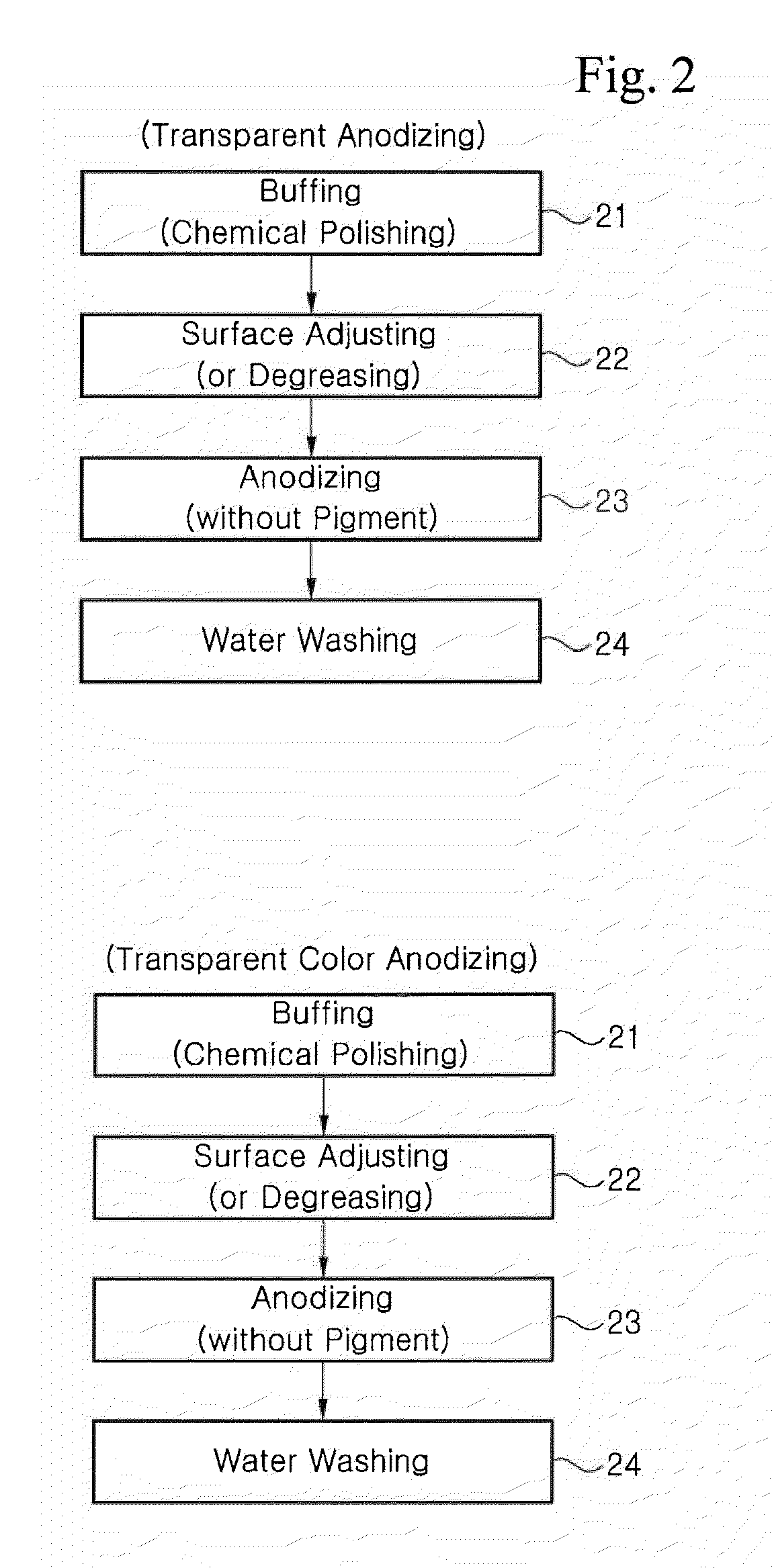

[0026]FIG. 1 is a flowchart illustrating a conventional method for treating a surface of a magnesium-based metal while FIG. 2 is a flowchart illustrating a method for treating a surface of a magnesium-based metal according to an embodiment.

[0027]As shown in FIG. 2, the surface treatment method according to this embodiment includes a buffing step 21, a degreasing or surface adjusting step 22, an anodizing treatment step 23 and a water washing step 24.

[0028]The buffing step 21 uses a chemical polishing scheme. After the buffing step 21 and the degreasing or surface adjusting step 22 are performed, the magnesium-based metal is immersed in a strongly alkaline electrolyte solution for an anodizing treatment, and then subject to the anodizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com