ECCENTRIC JET TYPE LOW NOx OXYFUEL BURNER

a burner and nox technology, applied in the direction of burners, combustion types, indirect carbon-dioxide mitigation, etc., can solve the problems of nitrogen oxide excessive generation, low flame stability and combustion efficiency, and inability to high-speed direct injection of fuel, so as to reduce the optimum mixture rate forming area, reduce the and reduce the effect of enlargement of the thin fuel area and the excessive fuel area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

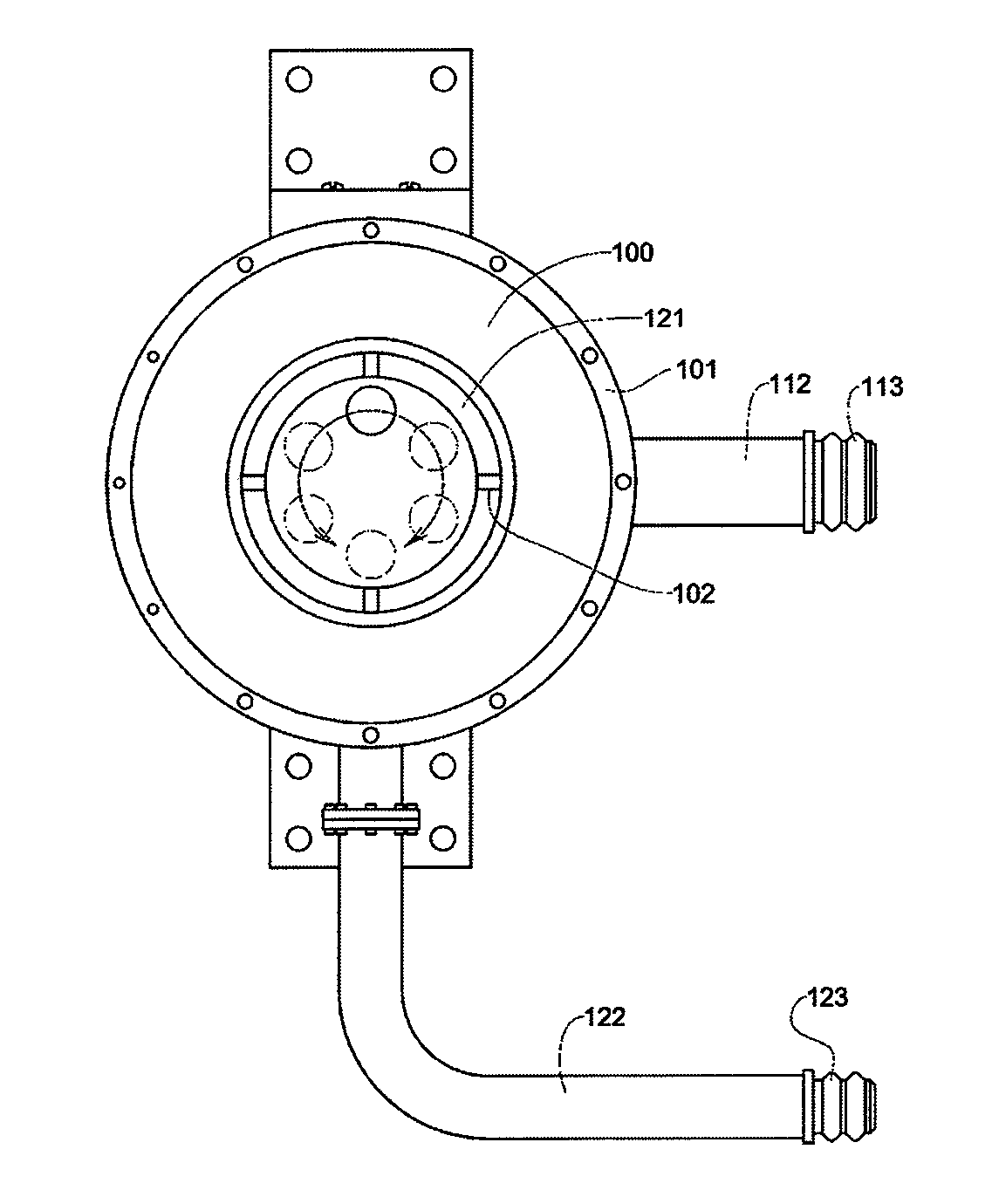

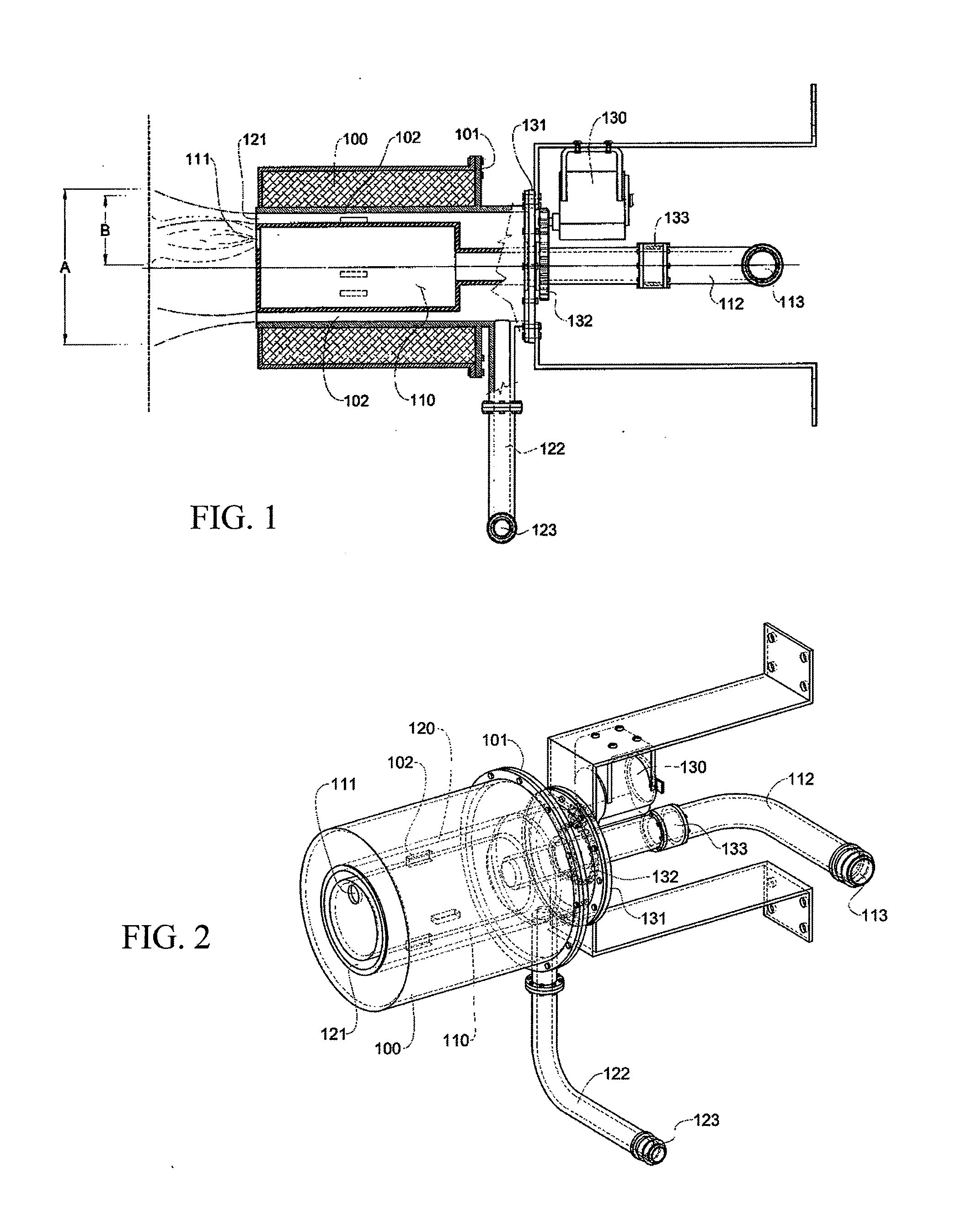

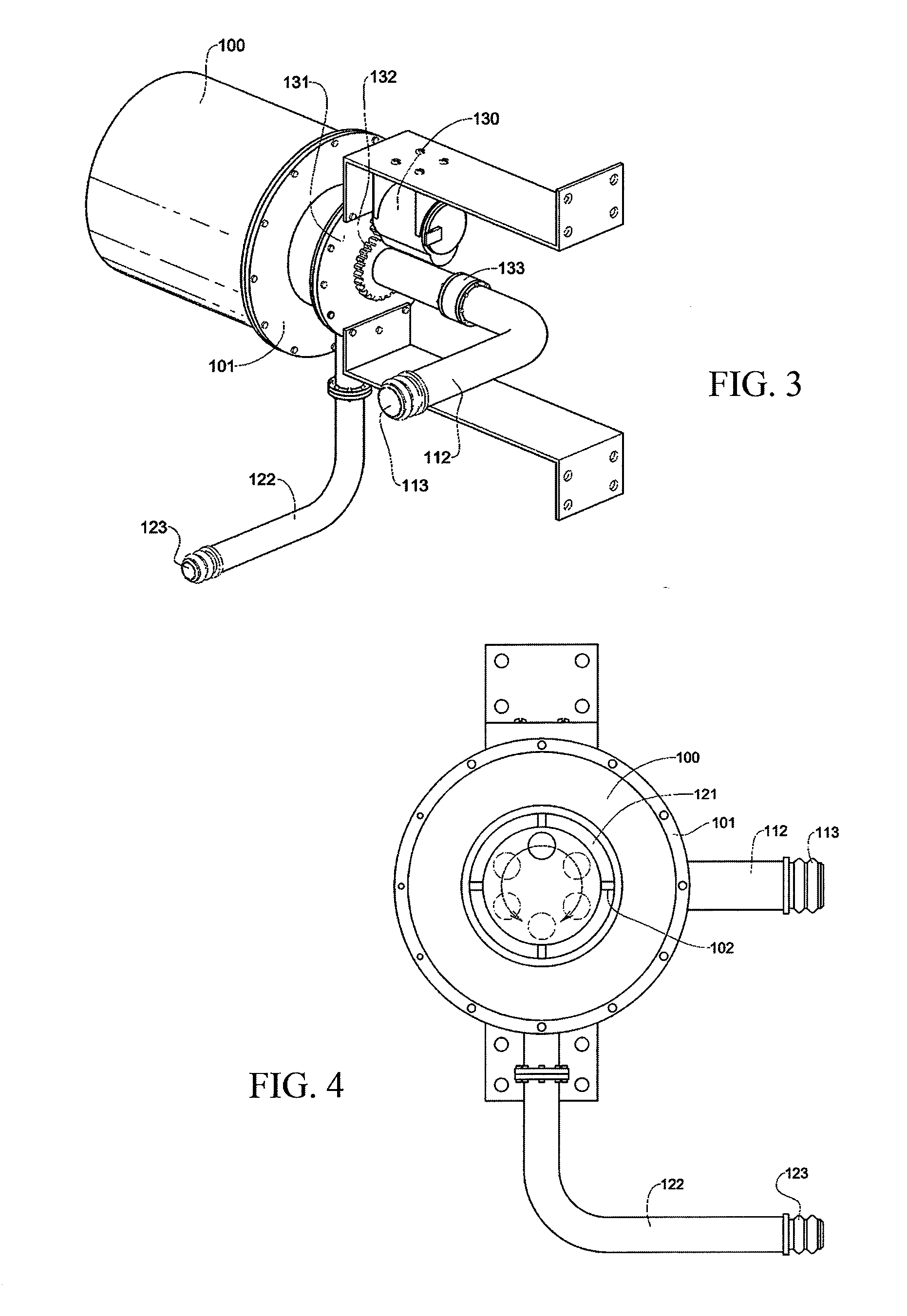

[0024]The present invention includes a fuel combustion pipe and an oxygen combustion pipe which have diameters different from each other respectively, and one combustion pipe is inserted into the other combustion pipe so that the one combustion pipe can rotate about a central axis of the other combustion pipe. Therefore, a mixture rate between oxygen and fuel can be freely controlled by an eccentrically provided nozzle of the one combustion pipe so that various combustion characteristics can be achieved.

[0025]The eccentric jet type low NOX oxyfuel burner for gaseous fuel, according to the present invention, includes an oxygen combustion pipe and a fuel combustion pipe.

[0026]The oxygen combustion pipe is inserted within a burner tile so as to be concentrically positioned with respect to the central axis of the burner tile, includes an oxygen feeding pipe connected to one side portion of the circumferential surface thereof so that oxygen is supplied through an oxygen feeding inlet pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com