Feeding device

a technology of feeding device and feed line, which is applied in the direction of loading/unloading, thin material processing, furnace, etc., can solve the problems of sinuous conveying line and occupies too much spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

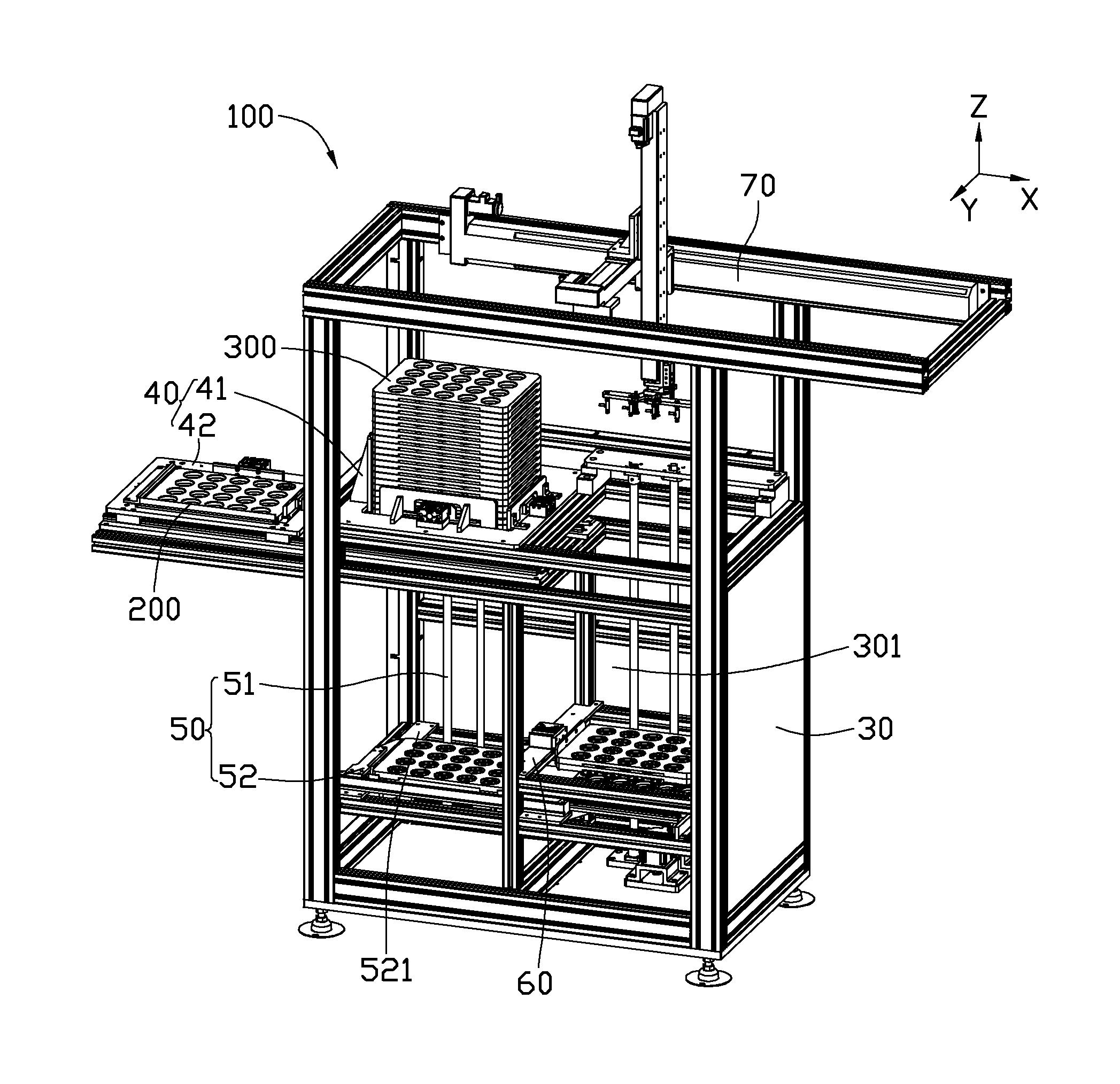

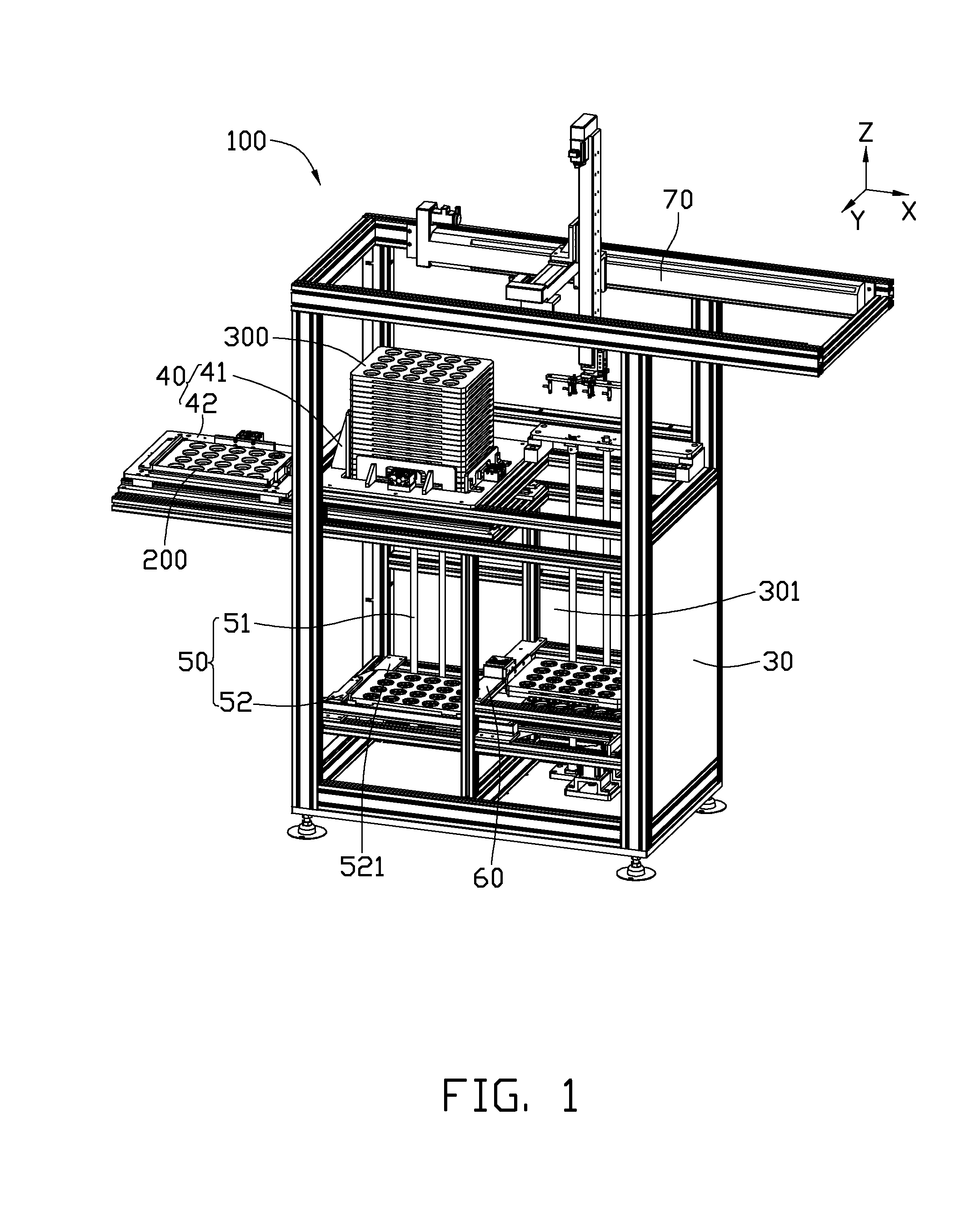

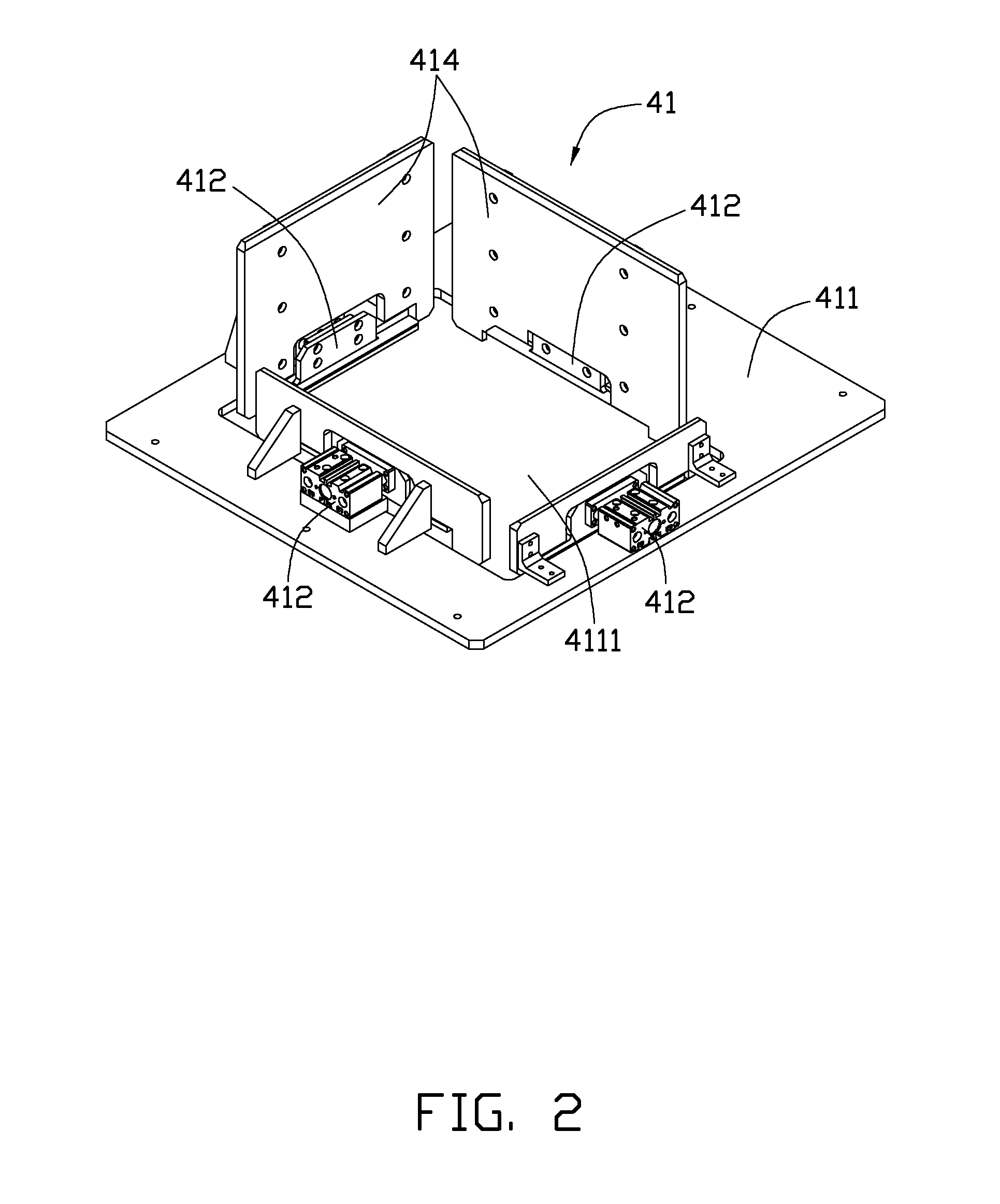

[0015]Referring to FIG. 1, one embodiment of a feeding device 100 is used for transferring feeding trays 300 for receiving workpieces 200 between a first station and a second station. The feeding device 100 includes a fixing frame 30, a first conveying mechanism 40, a second conveying mechanism 50, a stacking mechanism 60, and a handling mechanism 70. In the illustrated embodiment, the workpiece 200 is formed by injection, and then transferred from an injection station to a testing station for testing a size of the workpiece 200. When the workpiece 200 is newly formed, the temperature of the workpiece 200 is relatively high, and the size of the workpiece 200 is affected by the temperature. Therefore, the workpiece 200 needs to be cooled down to room temperature before testing, such that the feeding time between the injection station and the testing station is equal to or longer than the cooling time.

[0016]The fixing frame 30 is substantially rectangular, and defines a receiving spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com