Lightweight tile with tapered support

a technology of tapered support and light weight tiles, which is applied in the direction of roof coverings, building components, roofs, etc., can solve the problems of not offering the unique breathable, the roof is thin, and the application of optional ceramic or porcelain tiles is not offered. , to achieve the effect of thin ceramic or porcelain tile roof and strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

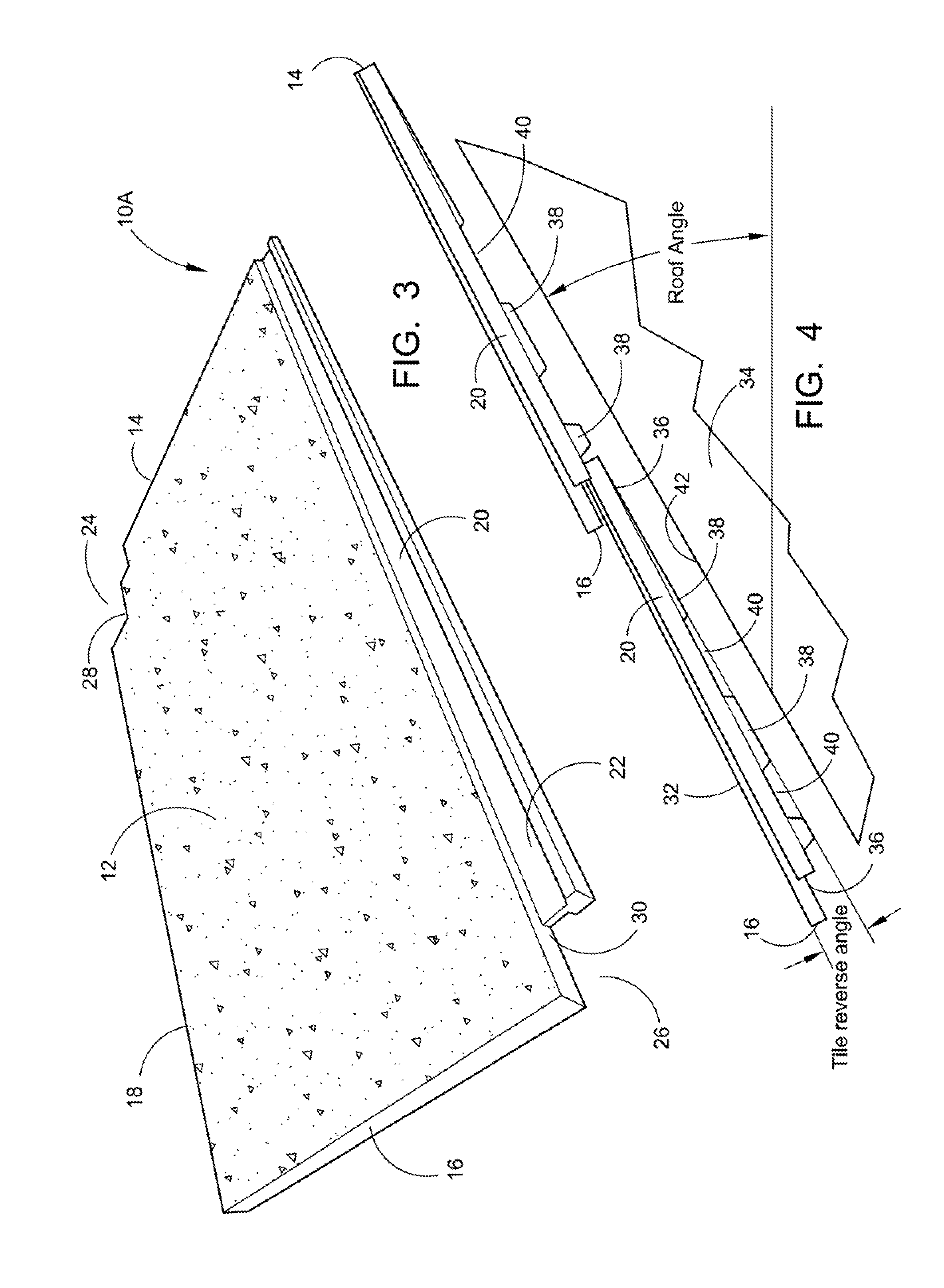

[0083]100831 Referring now to the drawings, wherein similar parts of the embodiments of the lightweight tile with tapered support 10A, 11B, 10C, 10D and 10E are identified by like reference numerals.

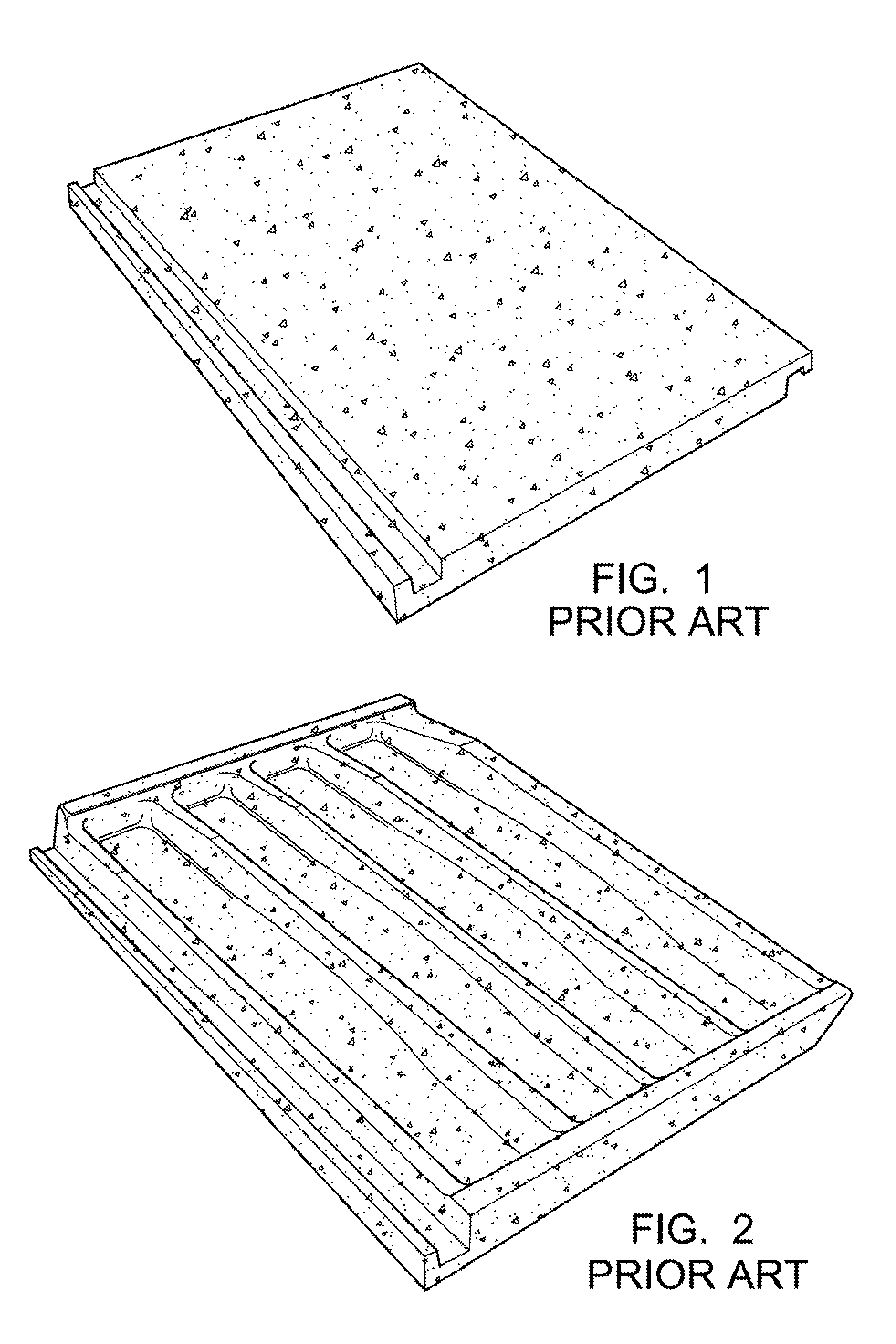

[0084]FIG. 1 a perspective view of the top side of a prior art concrete roofing tile.

[0085]FIG. 2 depicts a perspective view of the lower surface of a prior art concrete roofing tile.

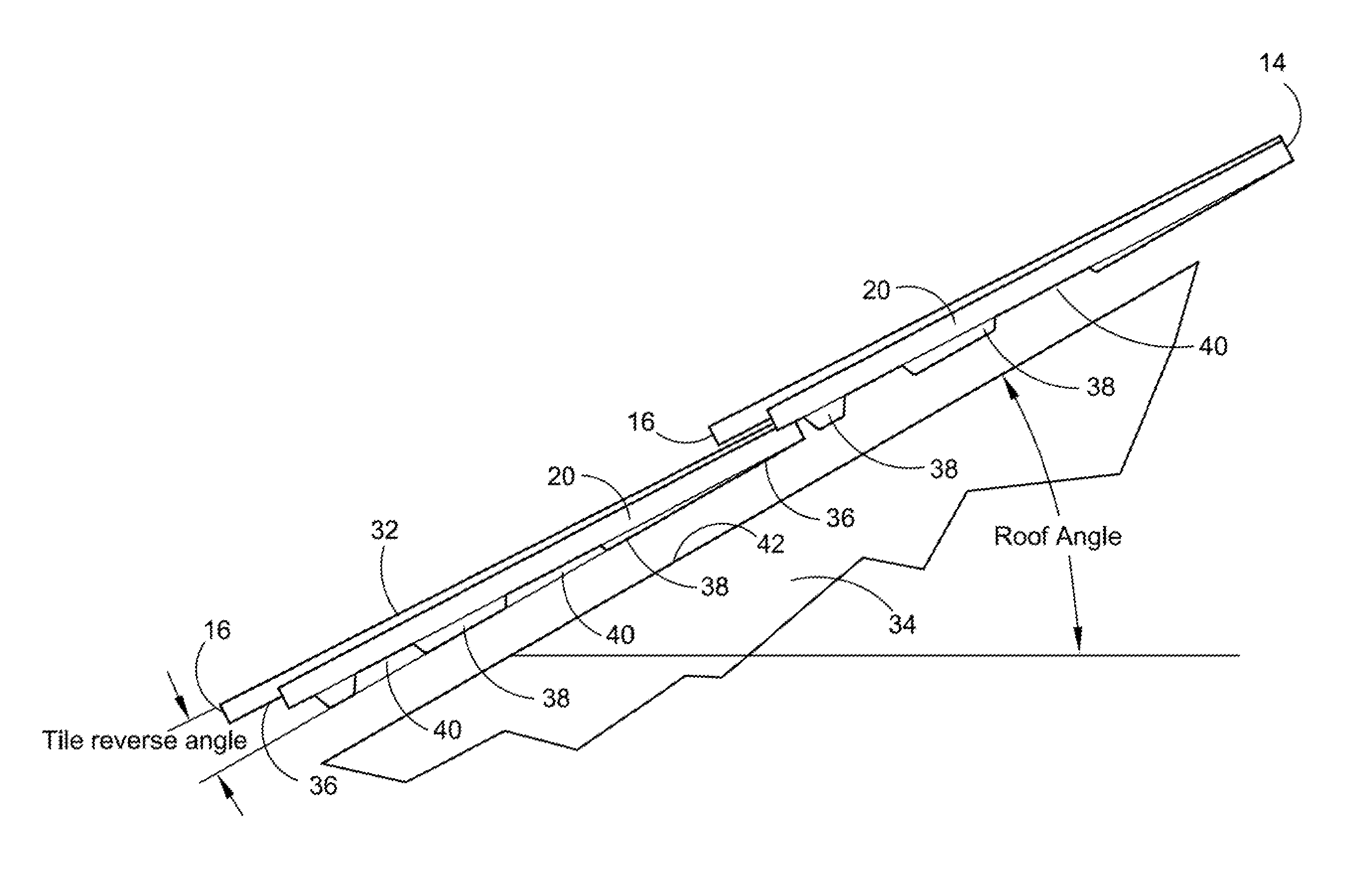

[0086]FIG. 3 depicts a perspective view of the upper surface 12 of the preferred embodiment of the lightweight the with tapered support 10A illustrating the upper end 14 and the lower end 16 with the left side 18 and the right side 20 with the interlocking drain trough 22. The upper left corner 24 and the lower right corner 26 have notches 28 and 30 for the purpose of locaters for the installation process and to create a step in the interlocking drain trough 22. The upper surface 12 will come in a variety of conventional textured surfaces. These tiles will not require battens attached to the roofs surface fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com