Vacuum compression storage bags

a vacuum compression and storage bag technology, applied in the field of vacuum compression storage bags, can solve the problems of preventing airflow through the valve and remaining taut in the bag, and achieve the effect of improving air flow and being simple and inexpensive to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

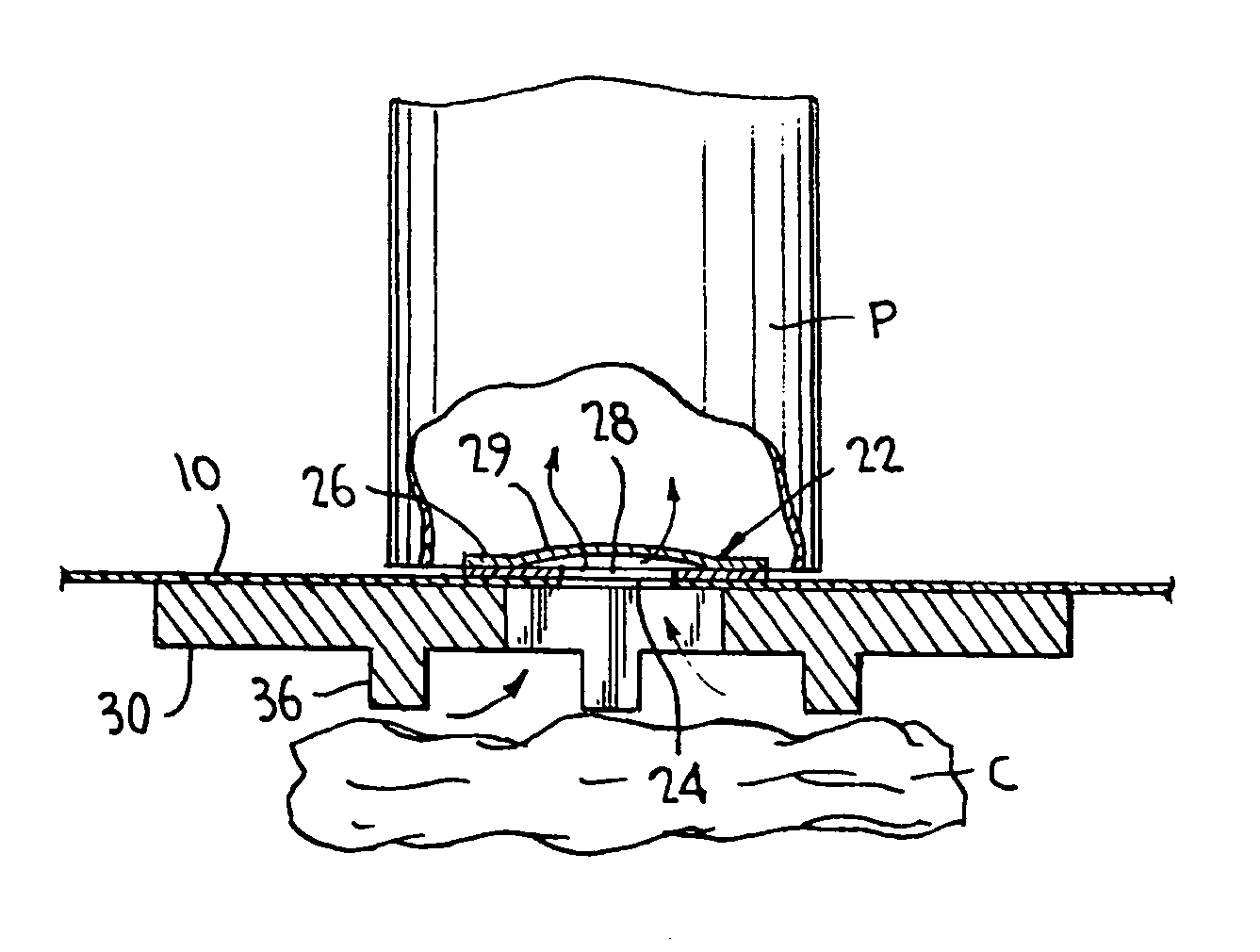

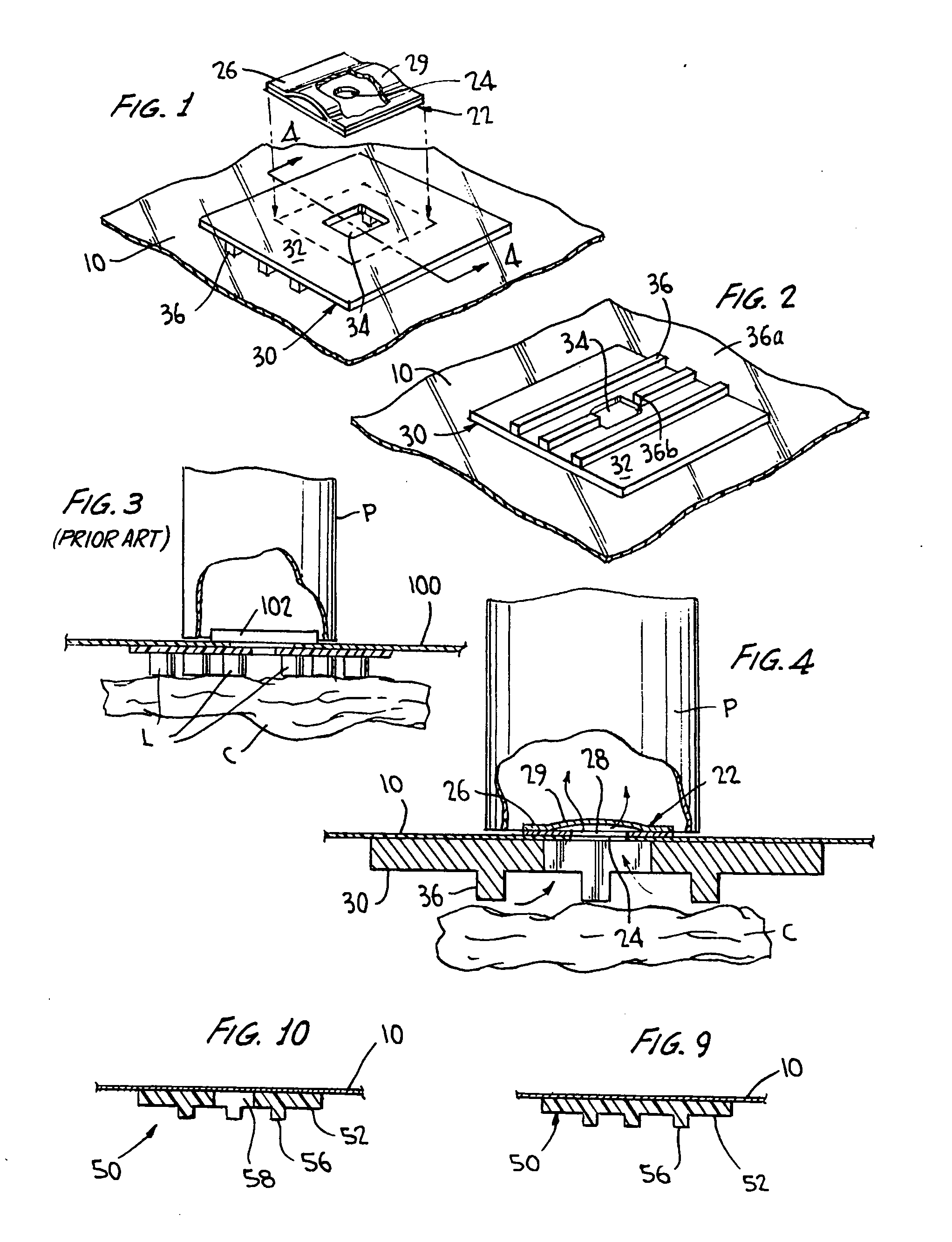

[0025]The present invention is directed to large vacuum compression storage bags which are simple and inexpensive to manufacture while providing substantially complete evacuation of air from the bag without the need for a complex and expensive valve and bag assembly. The storage bag of the invention includes a simple and inexpensive valve and an improved stand-off which provides for efficient evacuation of air from the storage bag after it is filled with the items, e.g. clothing, blankets and other material, to be stored and closed. The improved stand-off of the invention is preferably made by extrusion from a plastic material such as polyethylene. The stand-off is flexible and rigid, i.e. it has greater thickness than the storage bag walls. Other materials may also be used for the stand-off such as polypropylene, nylon or bioplastics.

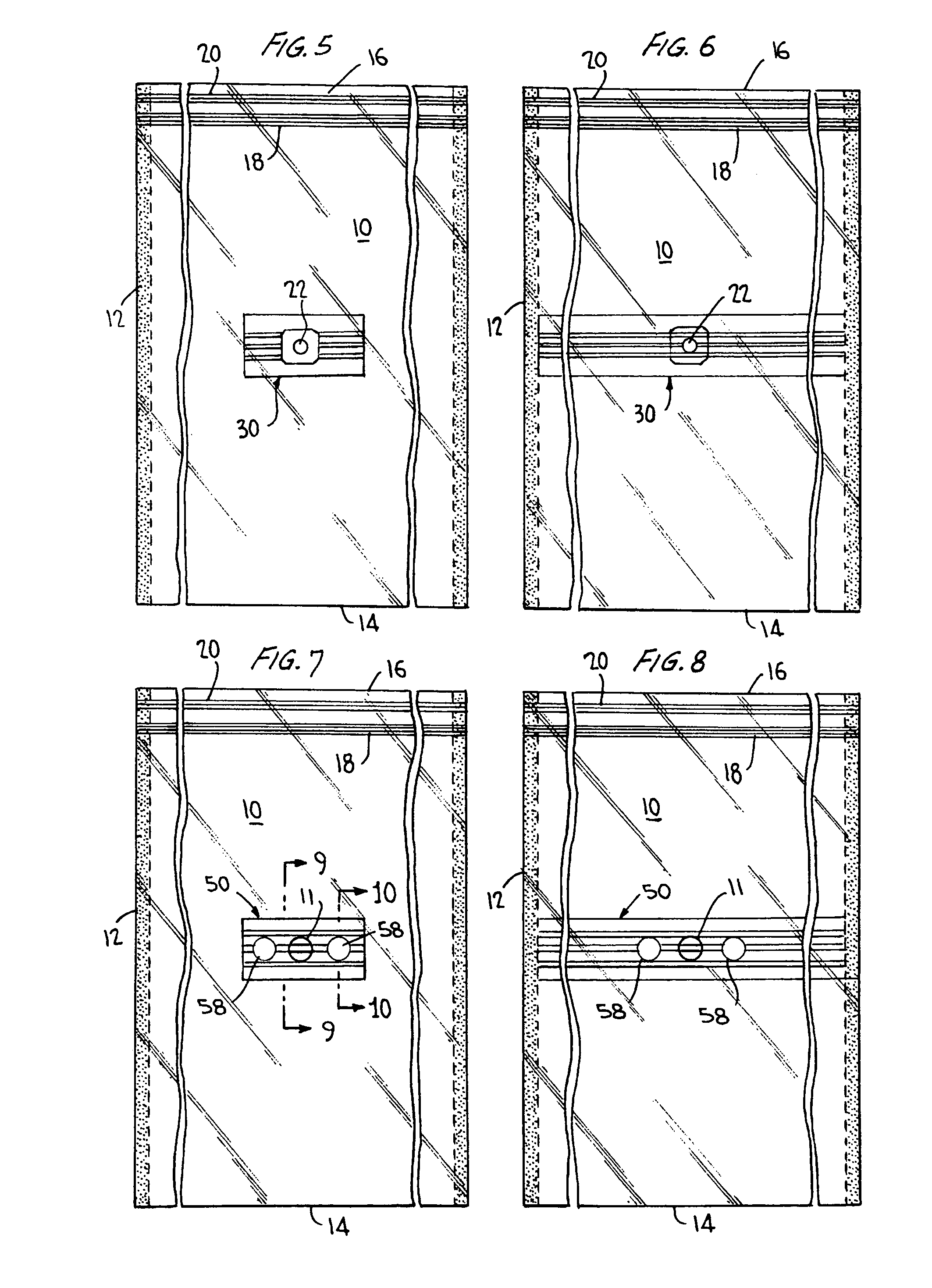

[0026]Referring generally to FIGS. 5-8, large vacuum compression storage bags, e.g. in the range of about 18 inches by 20 inches to about 35 inches to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com