Sealing plate and rotor blade system

a sealing plate and rotor blade technology, applied in the direction of blade accessories, leakage prevention, machines/engines, etc., can solve the problems that other vacuum investment casting processes are not possible, and achieve the effect of reducing material use and costs, simple design, and low production and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Like parts are provided with the same designations in all the figures.

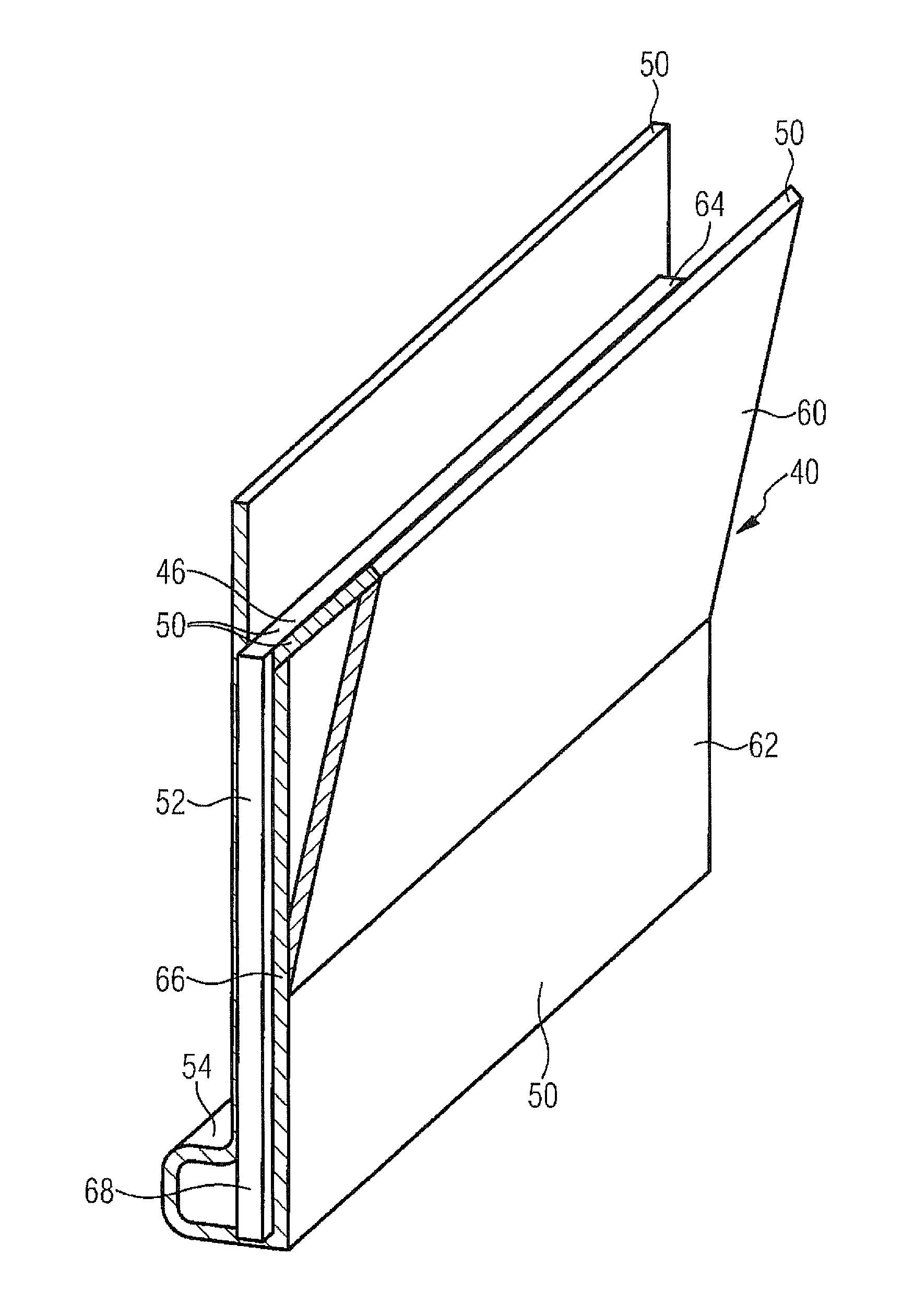

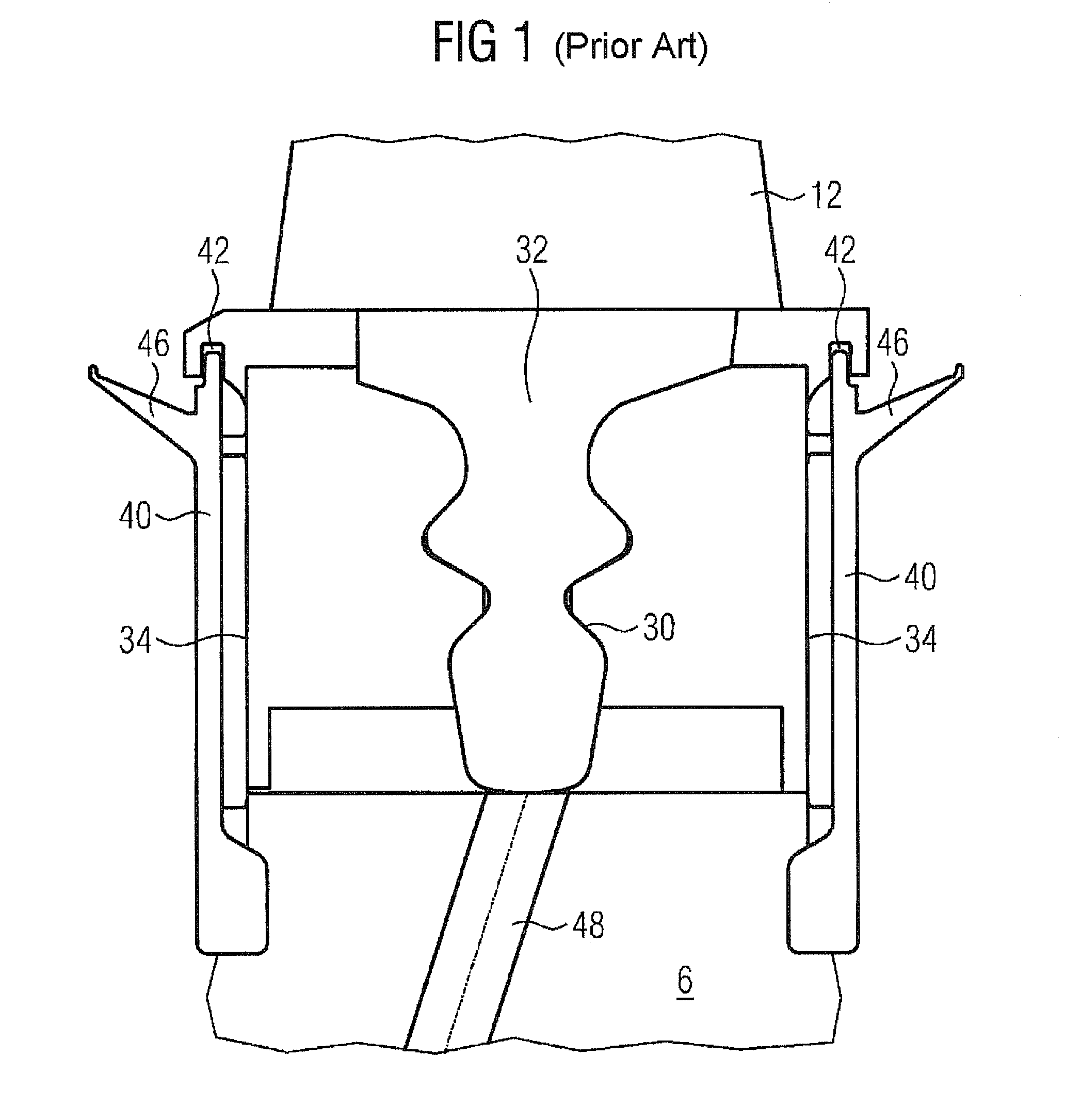

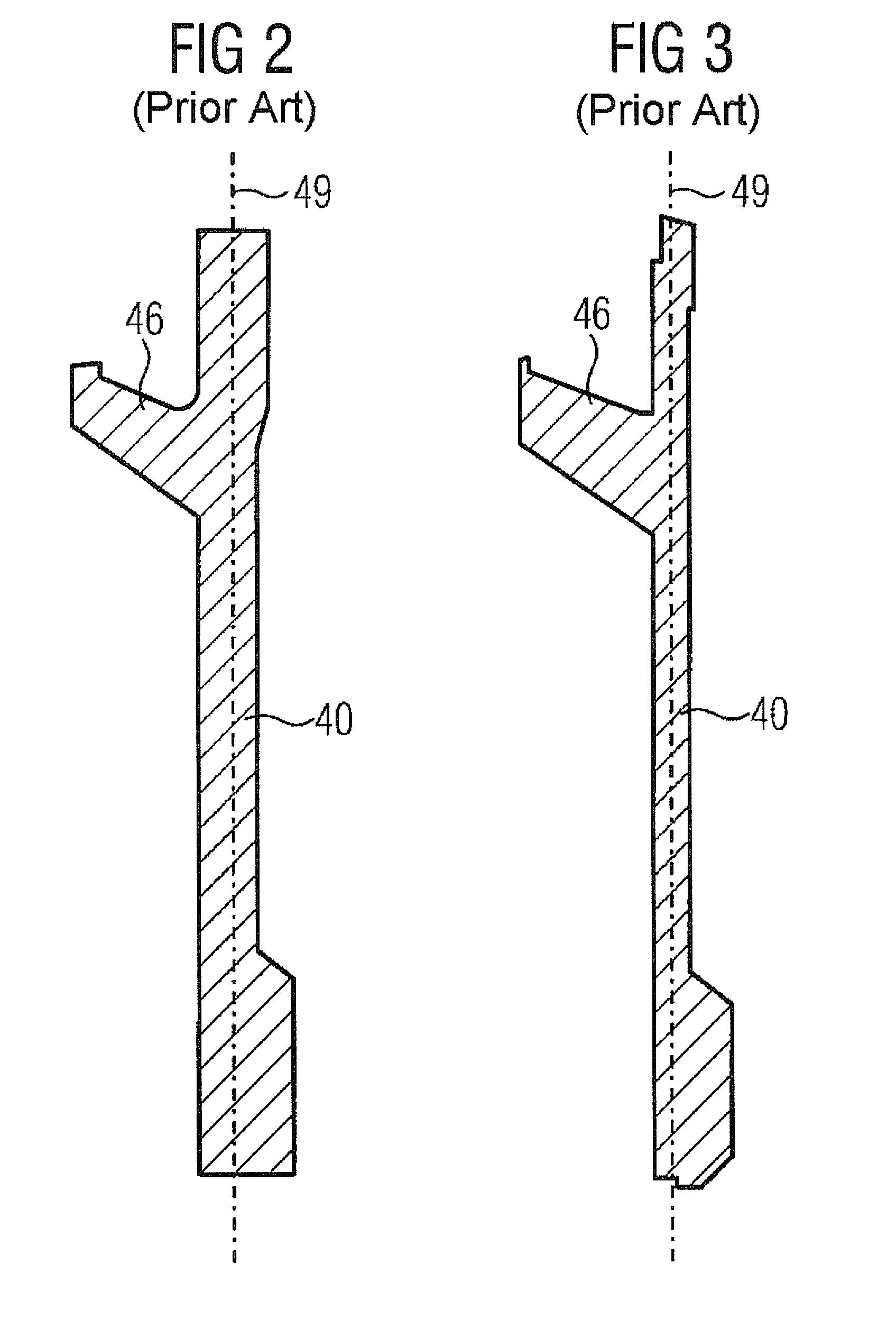

[0032]FIG. 1 shows a rotor blade system 1 as a section through the outer circumference of a turbine disk 6, attached on a turbine shaft, of a rotor blade stage of a gas turbine according to the prior art.

[0033]A rotor blade 12 is arranged in a rotor blade retaining slot 30 by its blade root 32 in this case. The blade root 32 of the rotor blade 12 is of a firtree shape in cross section and corresponds to the firtree shape of the rotor blade retaining slot 30. The schematic representation of the contour of the rotor blade root 32 and that of the rotor blade retaining slot 30 is reproduced in a manner rotated by 90° compared with the rest of the view of FIG. 2. Therefore, the depicted rotor blade retaining slot 30 extends between the side surfaces 34 of the turbine disk 6.

[0034]Adjacently provided in each case are stator blades 36, not shown in more detail, which are arranged upstream and downstream of the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com