Embossed plate external oil cooler

a technology of embossed plates and oil coolers, applied in the field of oil coolers, can solve the problems of difficult formation of more complex projections, and achieve the effects of easy fabrication and assembly, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

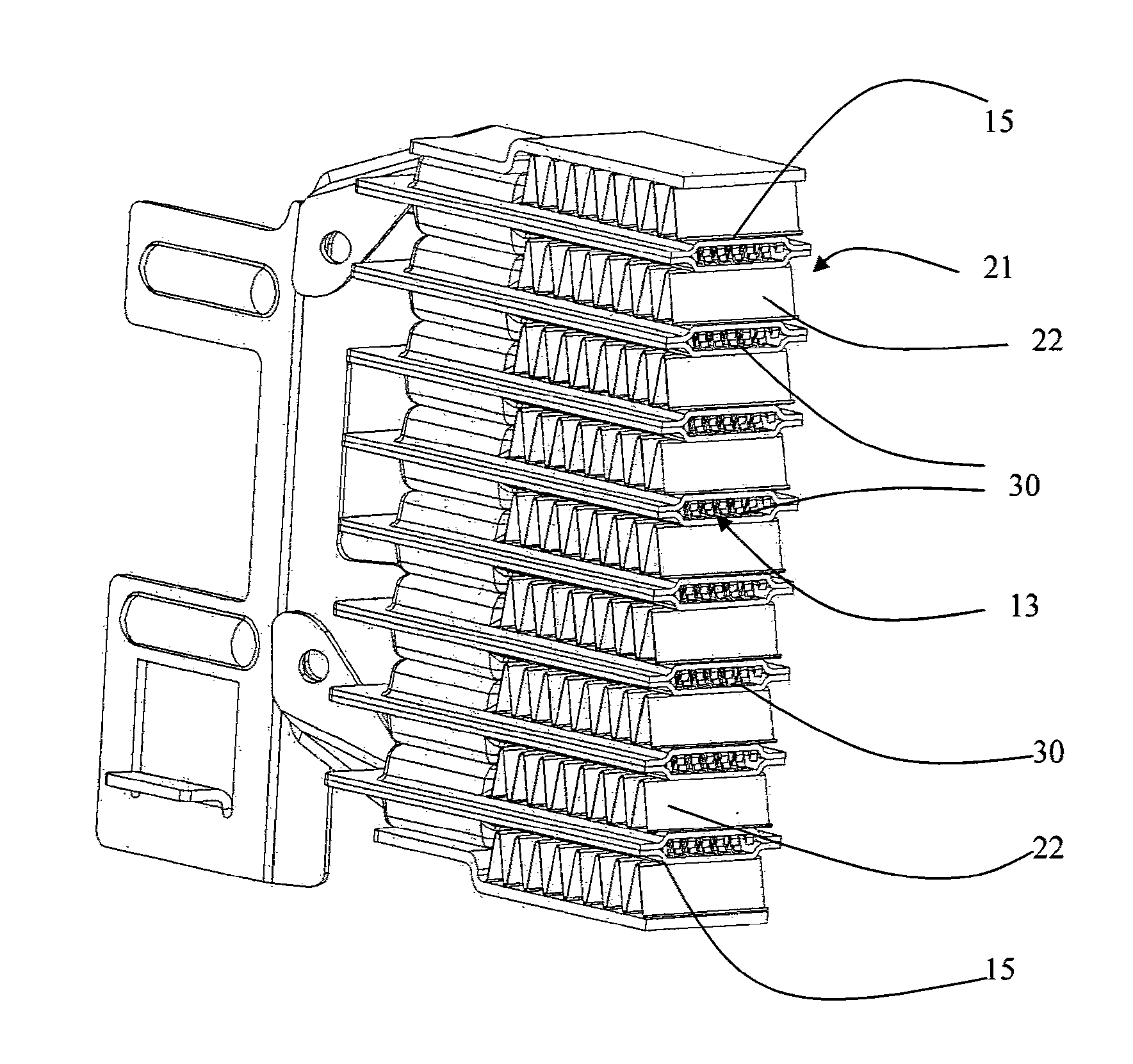

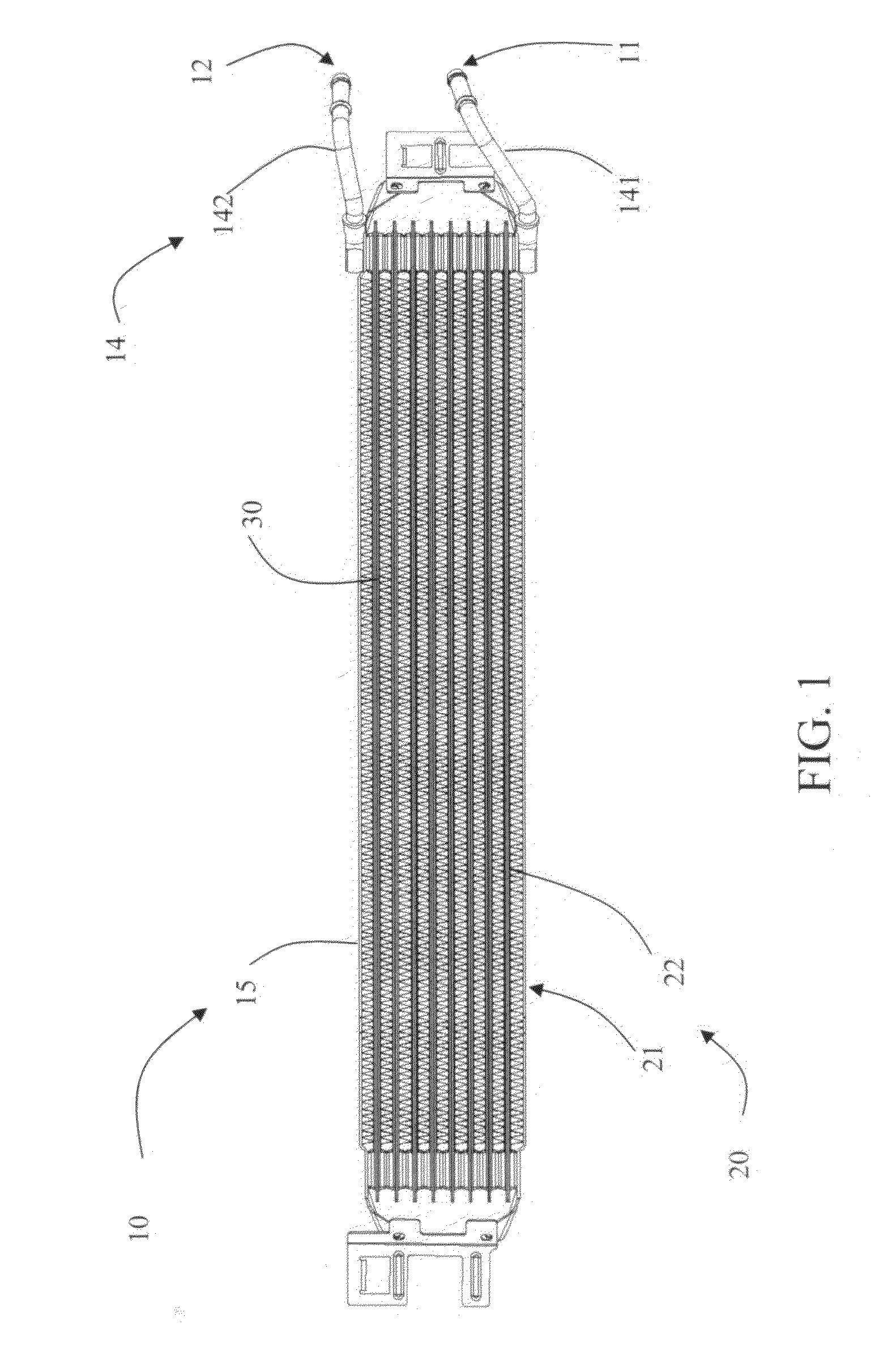

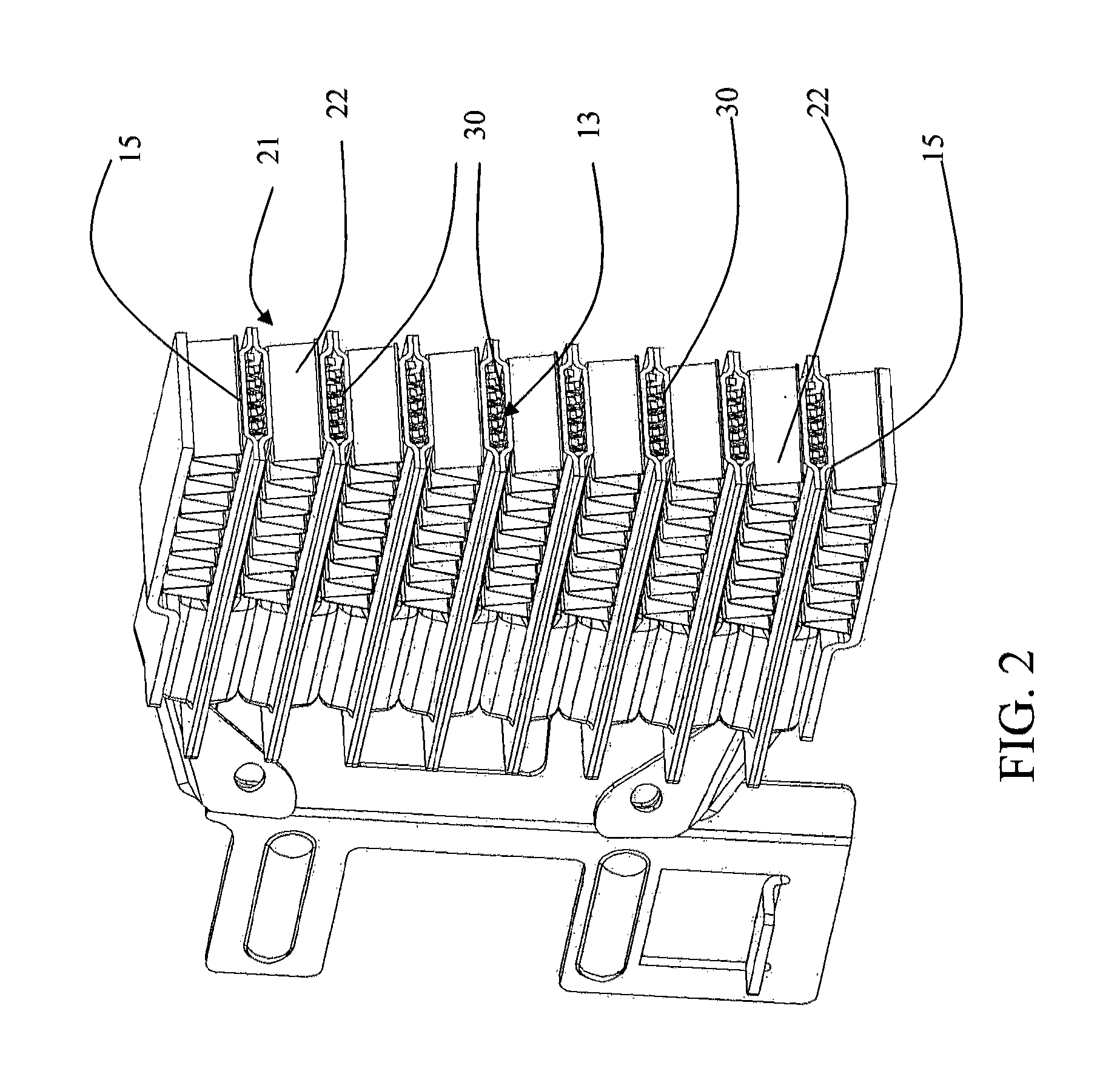

[0025]Referring to FIGS. 1 to 3 of the drawings, an oil cooler for exchanging heat with oil according to a preferred embodiment of the present invention is illustrated, wherein the oil cooler comprises and oil guiding arrangement 10 for guiding oil flowing from an oil inlet 11 to an oil outlet 12, and an air guiding arrangement 20 for guiding a medium, preferably fresh air, to exchange heat between the oil and the air of the medium, so as to cool down the oil before the oil existing the oil outlet 12.

[0026]The oil guiding arrangement 10 further comprises a plurality of oil passageways 13 communicatively extending from the oil inlet 11 to the oil outlet 12 of the oil guiding arrangement 10. The oil passageways 13 are preferably to be spacedly stacked with each other, so that the oil is guided to longitudinally flow from the oil inlet 11 to the oil outlet 12. In particularly, the oil passageways 13 are parallel with each other.

[0027]The air guiding arrangement 20 comprises a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com