Device for focusing a microscope objective on a sample

a technology for focusing microscopes and samples, applied in the field of devices for focusing microscope objectives on samples, can solve the problems of affecting the focusing accuracy, affecting the accuracy of focusing, and unable to change the microscope objective easily, and achieve the effect of accurate focusing on samples and high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

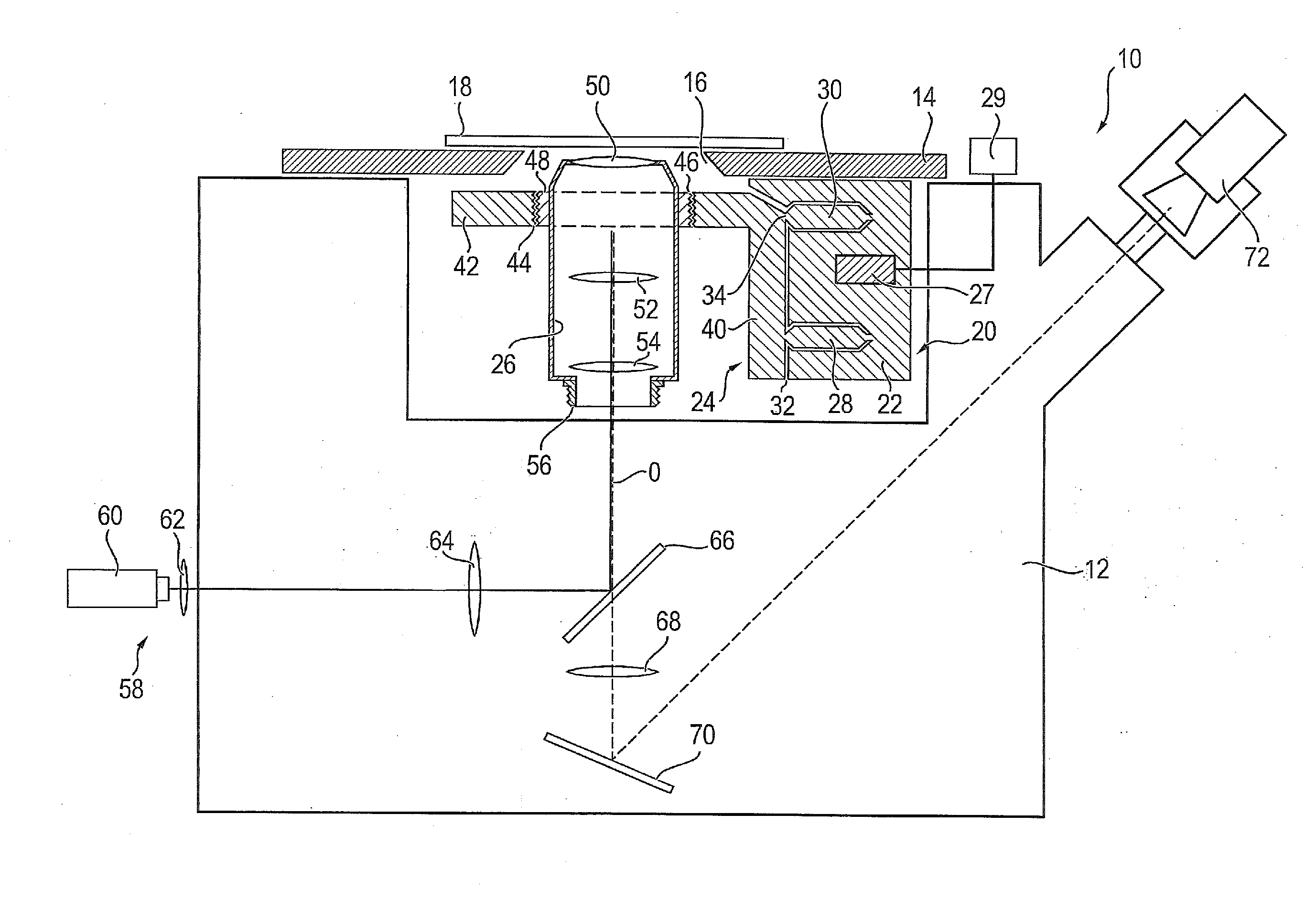

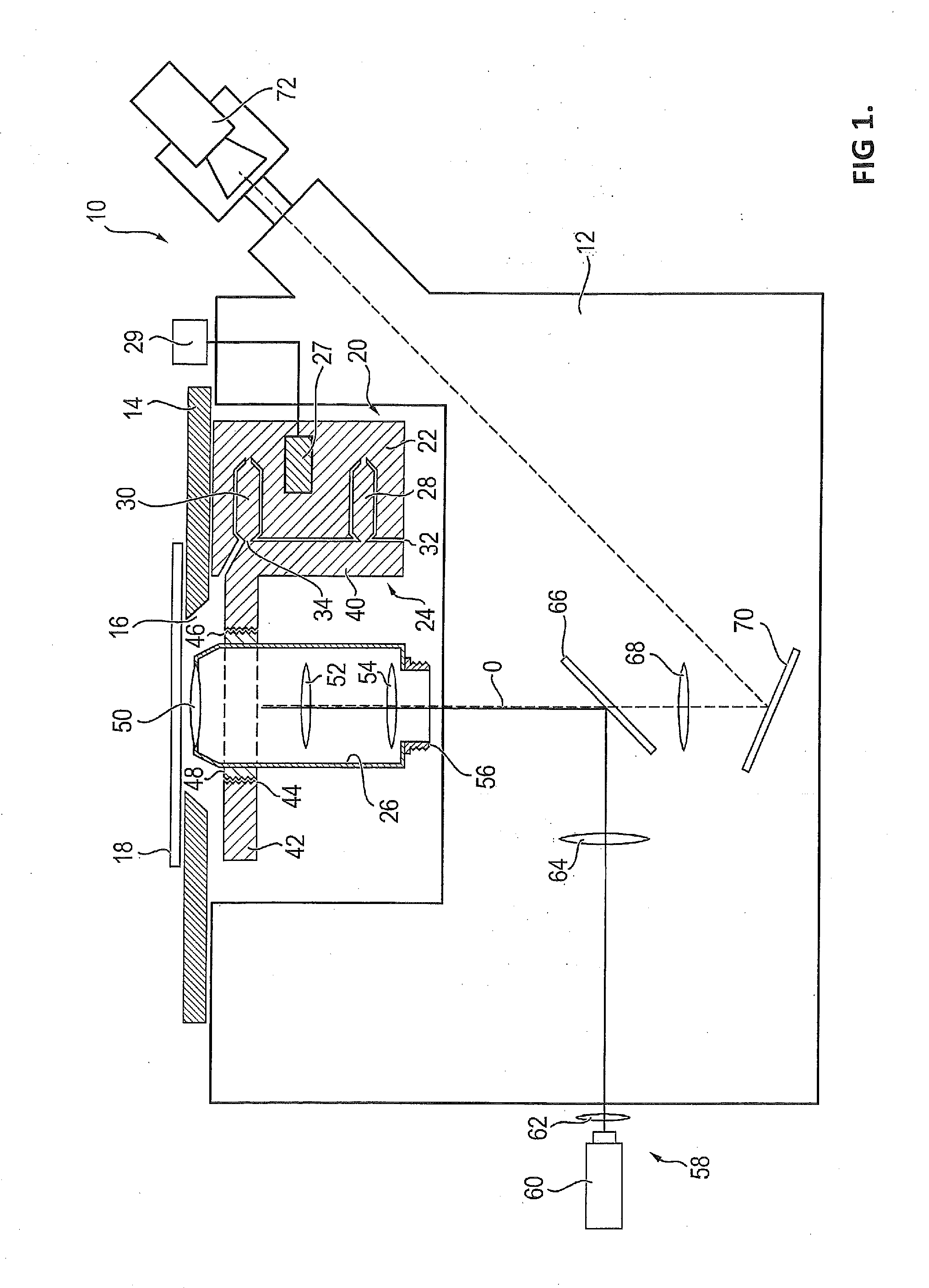

[0015]Thus, in contrast to the conventional systems where the microscope objective is held at the rear end; i.e., the end facing away from the sample (and usually by the thread provided at that end), it is a feature of the present invention that the microscope objective is held at a front portion facing the sample, which is where the so-called front lens is located. This is because it has been found that stabilizing the objective at its front end, as proposed by the present invention, has advantages over the conventional method of stabilizing it at its rear end when it comes to achieving the highest possible level of lateral resolution.

[0016]In a microscope objective, there is always a tilt-tolerant plane perpendicular to the optical axis, in which tilting of the microscope objective perpendicular to the optical axis does, at least in a first approximation, not result in image offset. This plane coincides with the first principal plane of the objective optical system. The exact posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com