Carbon nanotube film structure

a carbon nanotube and film structure technology, applied in the field of nanomaterial film structure, can solve the problems of poor utilization of excellent carbon nanotube properties, rather restricted application of carbon nanotubes, drawbacks and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

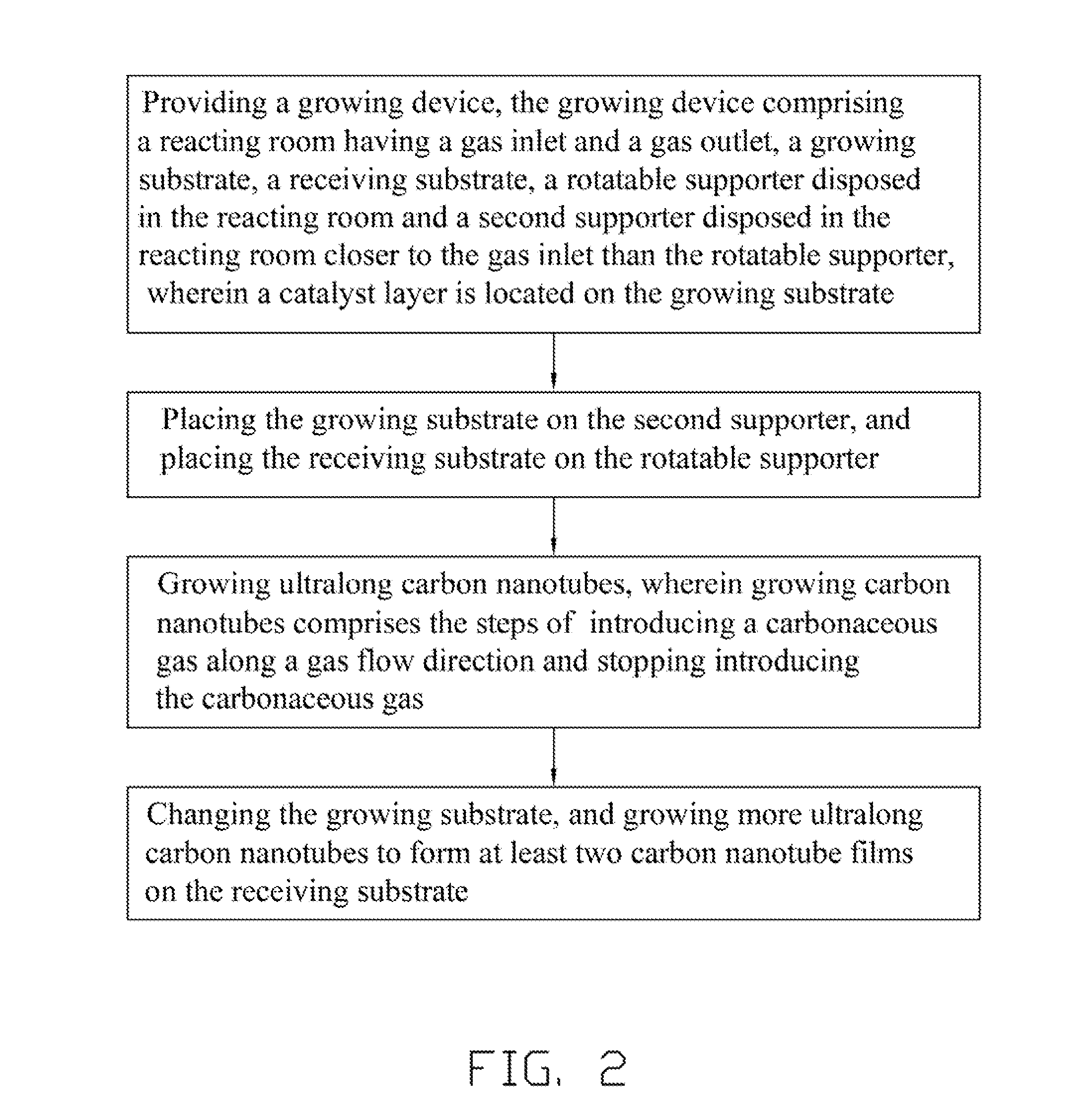

[0015]References will now be made to the drawings, in detail, to describe embodiments of the carbon nanotube film structure and the method for making the same.

[0016]Referring to FIG. 1, a carbon nanotube film structure 10 is provided in the present embodiment. The carbon nanotube film structure 10 includes one carbon nanotube film 102 or at least two stacked carbon nanotube films 102. A thickness of the carbon nanotube film 102 approximately ranges from 10 nanometers to 100 micrometers. The carbon nanotube film 102 includes a plurality of parallel ultralong carbon nanotubes 104 all of similar length greater than 1 centimeter, and arranged parallel to the surface of the carbon nanotube film 102. The adjacent ultralong carbon nanotubes 104 in the same carbon nanotube film 102 may be in contact with each other or be separated by a distance of up to 5 micrometers. The ultralong carbon nanotubes 104 in the carbon nanotube film 102 are selected from the group comprising single-walled carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com