Method for manufacturing cold-forged wing bolts

a technology of cold-forged wing bolts and manufacturing methods, which is applied in the direction of threaded fasteners, bolts, other domestic articles, etc., can solve the problems of affecting the quality of the finished product, the inability to possess close-fitting strength of the metal material, and the chapped and loosening of the riveting portion, so as to reduce waste materials, increase quality and production capacity, and increase economic gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

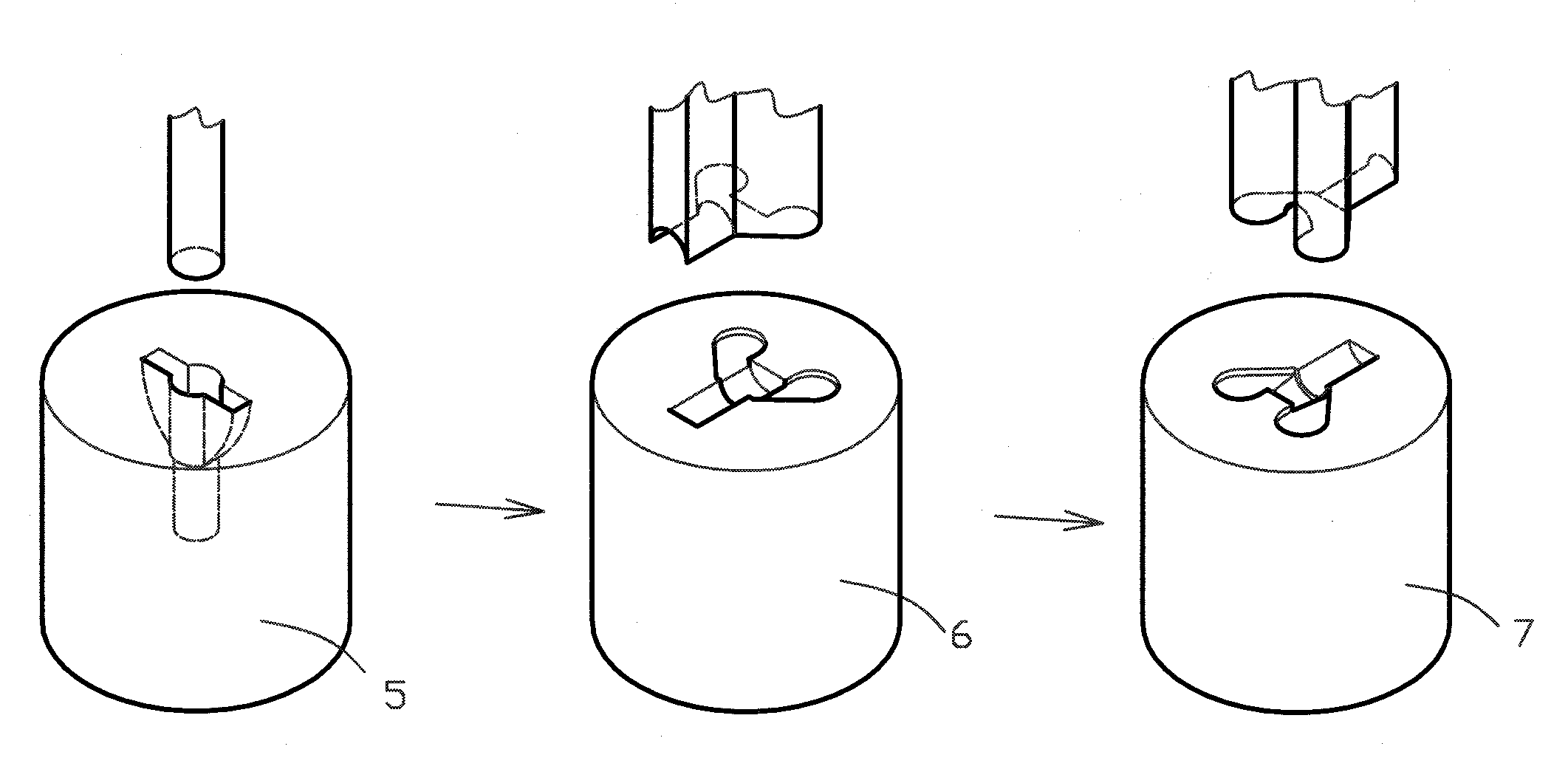

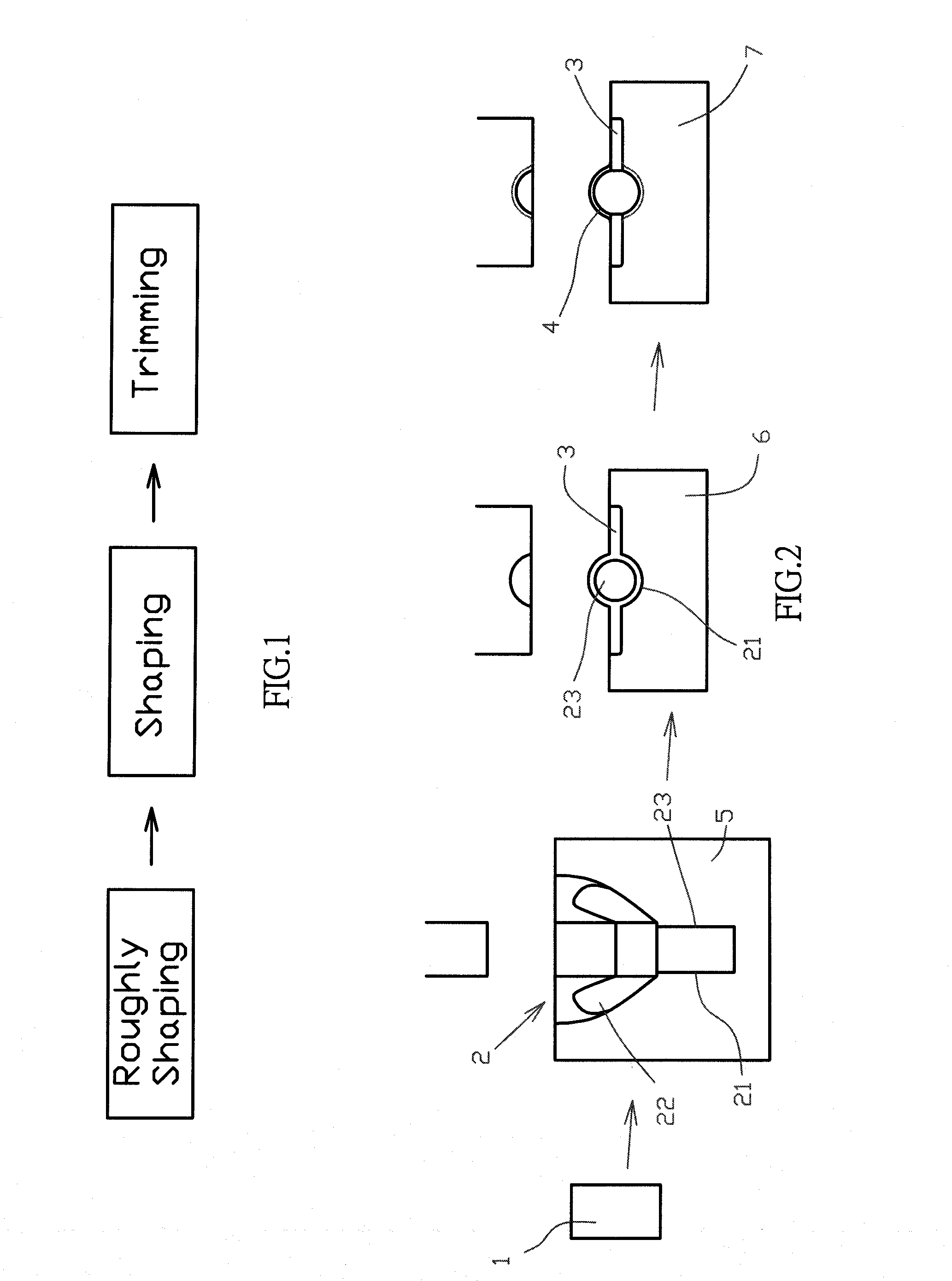

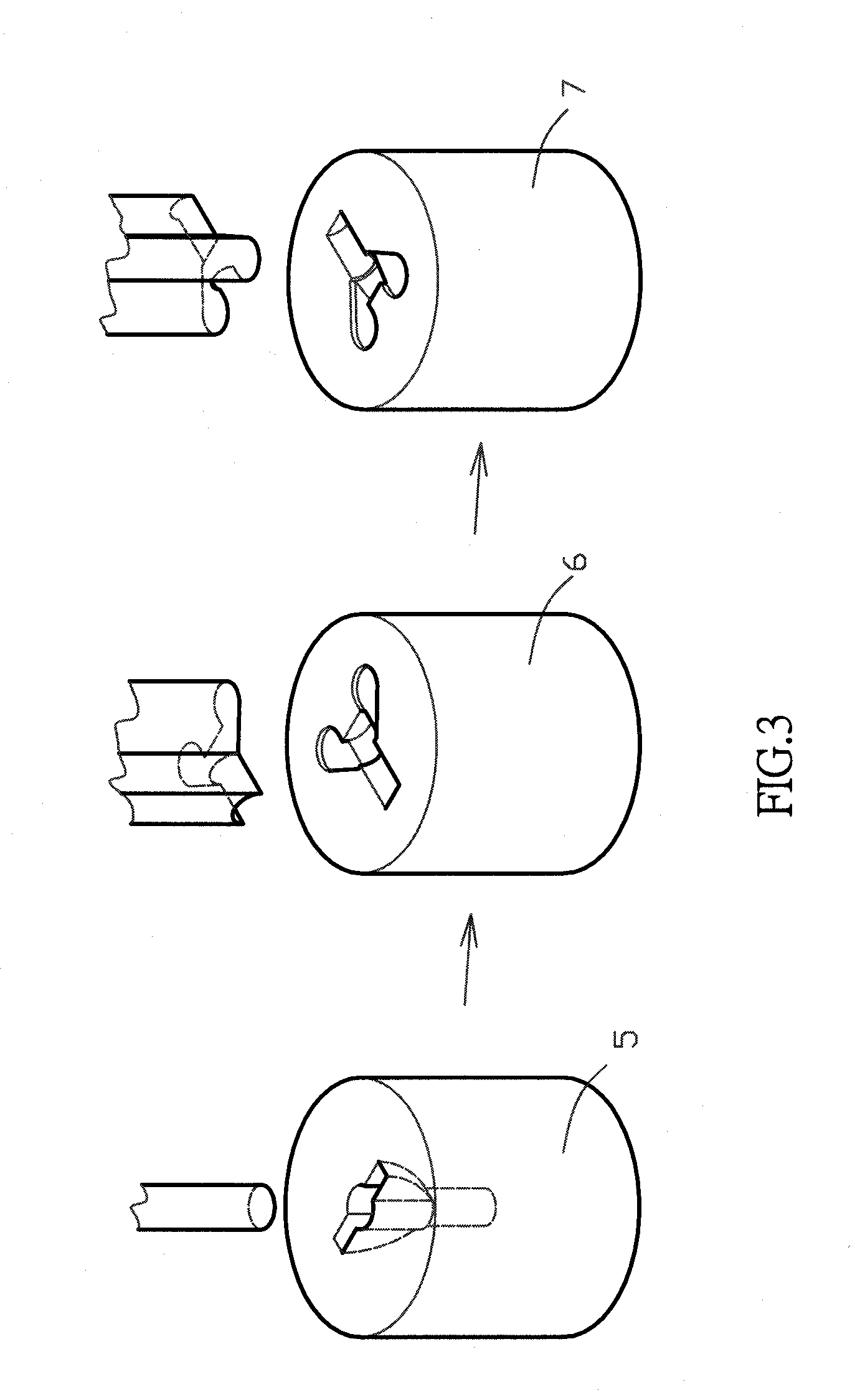

[0026]A preferred embodiment of a method for manufacturing cold forged wing bolts 5 in the present invention, as shown in FIGS. 1-4, needs a cold-forging machine, and includes several manufacturing processes. Referring to FIGS 2, 3 and 4, the manufacturing processes of wing bolts of this invention is orderly described as follows.

[0027]1. A first step of roughly shaping: A short basic rod 1 cut from a solid linear metal material is placed in a roughly-shaping mold set 5, slightly and gradually cold-forged and compressed therein, letting the upper section of the short basic rod 1 molded into a circular base 21 having opposite sides respectively extending upward to form a plate wing 22 with a pointed tip, and the lower section of the basic rod 1 formed into a smooth circular member 23, thus forming a roughly-shaped unfinished wing bolt 2.

[0028]2. A second step of shaping: The roughly-shaped unfinished wing bolt 2 finishing the first step is turned for 90 degrees and horizontally placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| mechanical combination | aaaaa | aaaaa |

| combination strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com