Method of forming a heat dissipating structure

a heat dissipating structure and extrusion molding technology, applied in the direction of manufacturing tools, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of difficulty in rapidly producing ventilated structures, and achieve the effect of enhancing the air-cooling efficiency of the heat dissipating structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

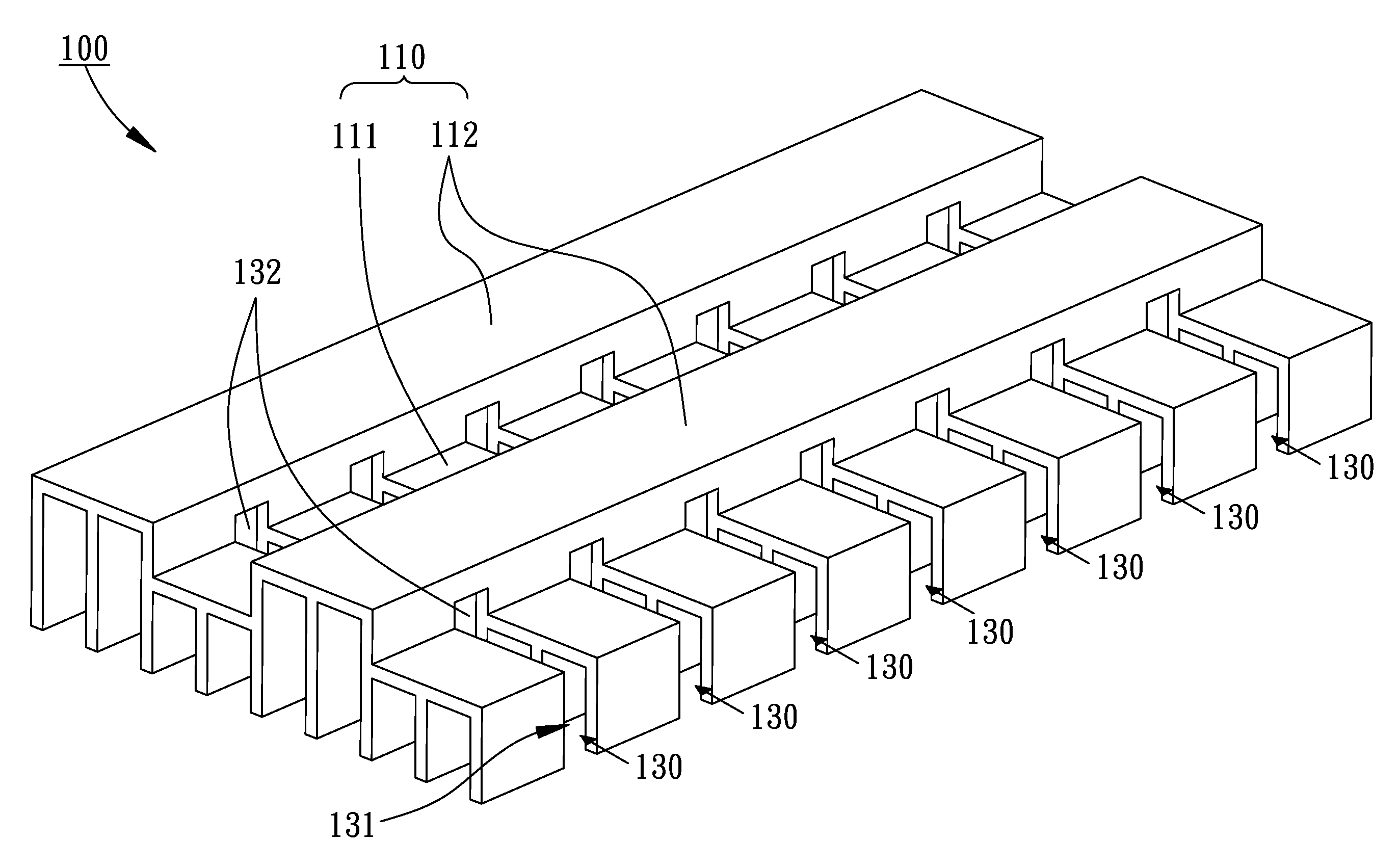

[0034]Referring to FIGS. 2, 3, and 4, a heat dissipating structure 100 according to the present invention is shown. The heat dissipating structure 100 includes an extrudate 110 and a plurality of fins 120, wherein the extrudate 110 and the fins 120 are formed monolithically by extrusion molding, and cooling air can flow through the extrudate 110 to enhance the air-cooling effect.

[0035]FIG. 5A is a cross-sectional view along line A-A′ in FIGS. 3 and 4. As shown in FIG. 5A, the extrudate 110 is formed by extrusion molding, the extrudate 110 can be a single sheet or a tubular structure. The extrudate 110 includes a plurality of bent portions 111 and a plurality of connecting portions 112 disposed alternately, and the bent portions 111 and connecting portions 112 extend in a longitudinal direction of the extrudate. The connecting portions 112 are provided for connecting the adjacent bent portions 111, and the bent portions 111 protrude from a surface of the extrudate 110. Since the extr...

second embodiment

[0043]FIGS. 8, 9, 10, and 11 a heat dissipating structure 200 according to the present invention is shown. The heat dissipating structure 200 includes an extrudate 210 and a plurality of fins 220, wherein the extrudate 210 and the fins 220 are monolithically formed by extrusion molding. The extrudate 210 includes a plurality of bent portions 211 and a plurality of connecting portions 212 disposed alternately, and the bent portions 211 and connecting portions 212 extend in a longitudinal direction. The connecting portions 212 are provided for connecting the adjacent bent portions 211, and the bent portions 211 protrude from a surface of the extrudate 210. The bent portion 211 includes a first protruding portion 2111 and a second protruding portion 2112 adjacent to each other on the cross-section, wherein the height of the first protruding portion 2111 protruding from the connecting portions 212 is larger than that of the second protruding portion 2112 protruding from the connecting p...

third embodiment

[0048]Referring to FIGS. 18, 19, and 20, the heights of the cutting lines of cut channels 330 determine whether cut-through slots 332 are formed at the bent portions by the cutting tool 900 as well as the cutting depths of the cut-through slots 332. The heights of the bent portions are unequal. When the cutting tool 900 is fed toward the surface of the extrudate 310, the fins 320 are cut at first, then the bent portions having relative higher height are cut to form the cut-through slots 332, and afterward the bent portions 311 having relative lower height are cut. In the third embodiment, the bent portions at least include a first bent portion 3111, a second bent portion 3112, and a third bent portion 3113. The first bent portion 3111, the second bent portion 3112, and the third bent portion 3113 are designated for illustration, instead of limiting the number of the bent portions.

[0049]Referring to FIG. 18, when the cutting tool 900 is continuously fed to make the cutting depths of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| heights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com