Vapor chamber with improved sealed opening

a technology of vapor chamber and sealing opening, which is applied in the field of heat pipes, can solve the problems of limiting affecting the operation of vapor chambers, and affecting the operation of indirect heat exchangers, etc., so as to improve the availability of vapor chambers, reduce manufacturing costs and processes, and increase the effect of availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

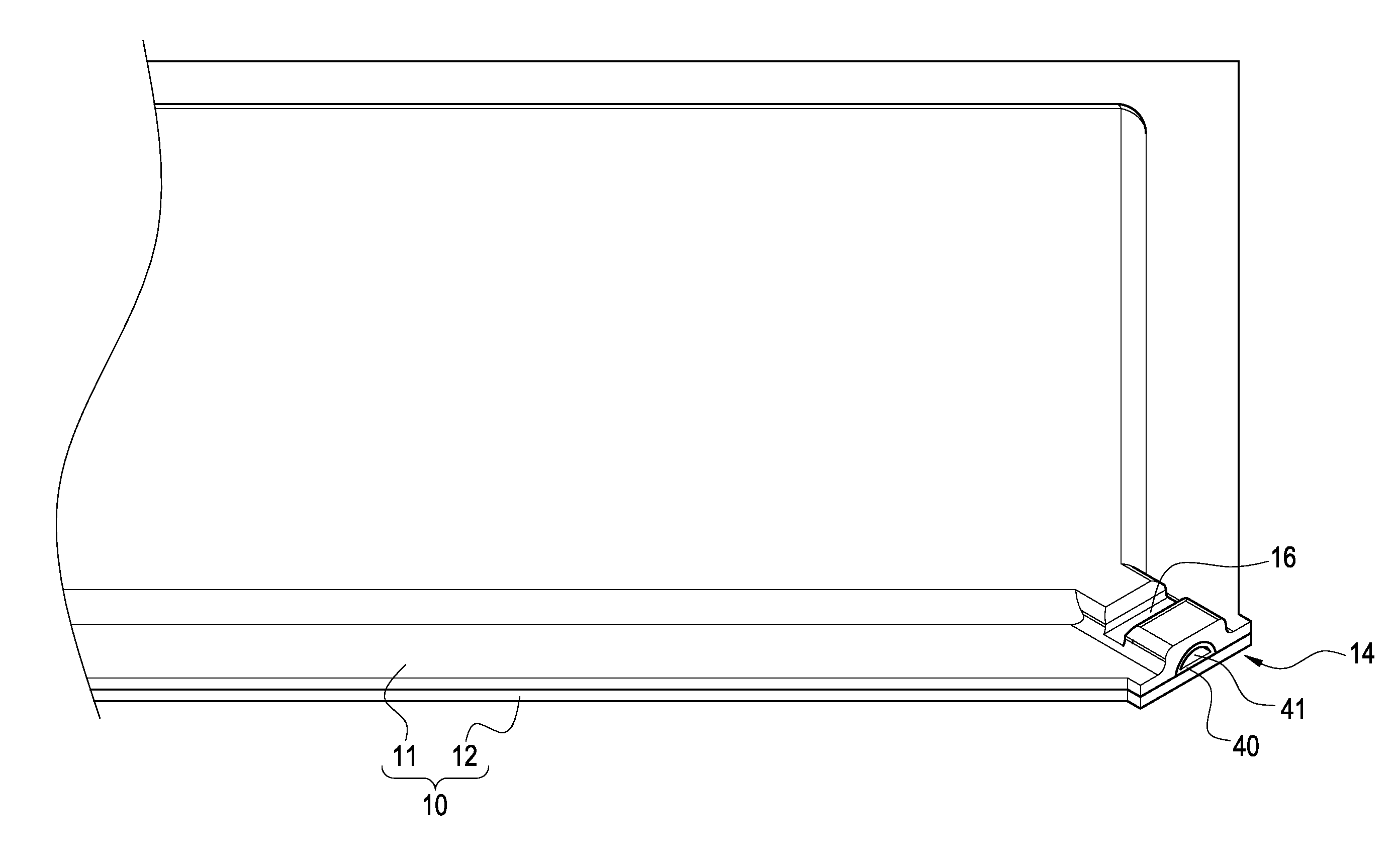

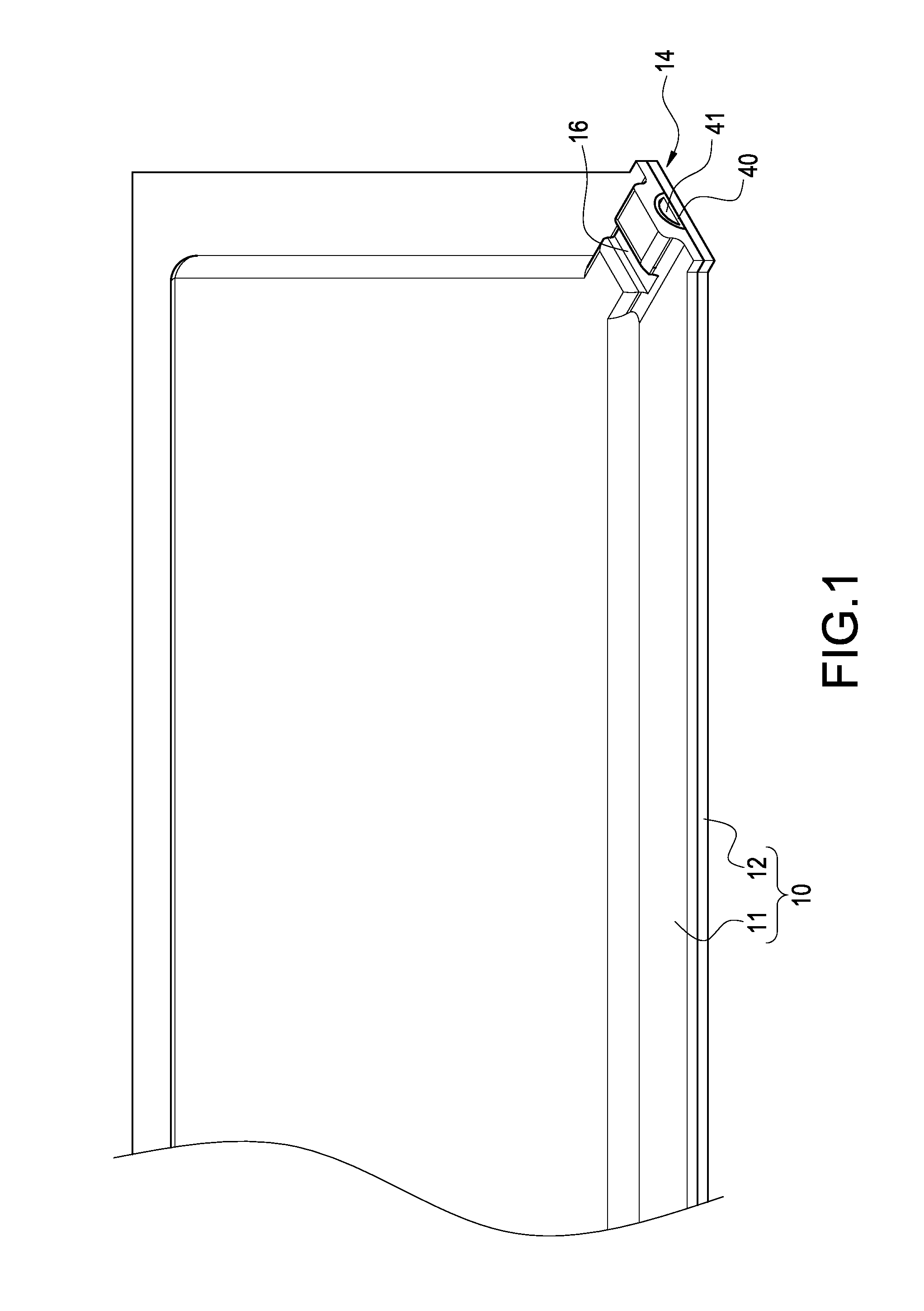

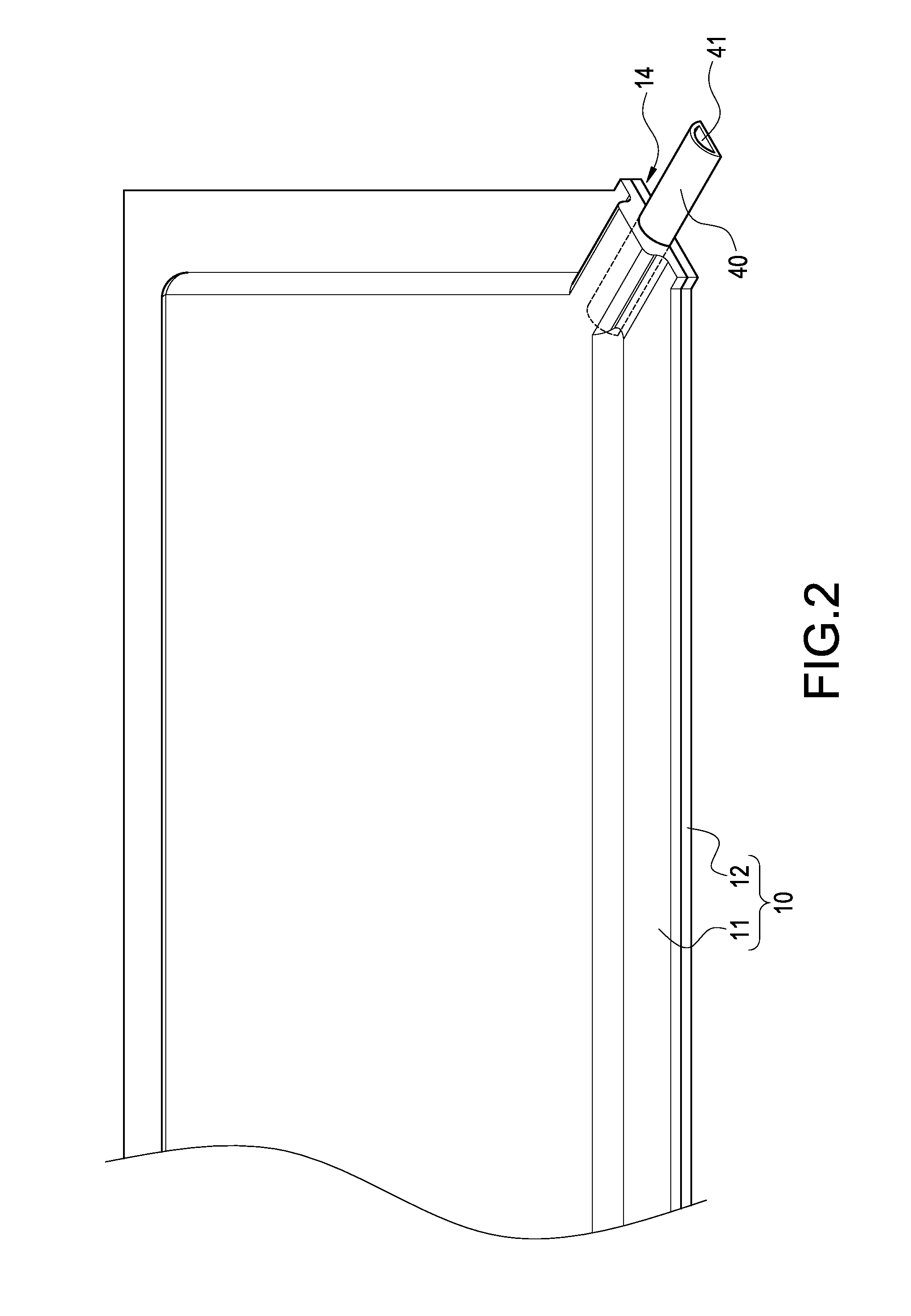

[0017]Please refer to FIG. 1. The vapor chamber of the invention includes a casing 10, a wick structure 20, a working fluid 30 and a filling / degassing tube 40.

[0018]The casing 10 is made of copper or copper alloy. In this embodiment, the casing 10 is composed of an upper plate 11 and a lower plate 12. Each of the two plates 11,12 is of a substantially rectangular shape. A periphery of the overlapping plates 11,12 is sealed by welding to form a chamber 13 therein. An angle of the casing 10 is formed with a truncated angle 14. The upper plate 11 is arced at the truncated angle 14 to form an insert channel 15 which communicates with the chamber 13.

[0019]The wick structure 20 may be metal mesh, fiber bundle or sintered metal powder. It is attached on the plates 11,12 in the chamber 13. The wick structure 20 provides a capillary force to make liquid working fluid 30 flow back.

[0020]The work fluid 30 may be water and is filled in the chamber 13. Under a room temperature, the work fluid 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com