Vessel hull configuration

a technology for hulls and vessels, applied in the field of marine vessels, can solve the problems of increased construction costs and injustification of extra length for longer vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

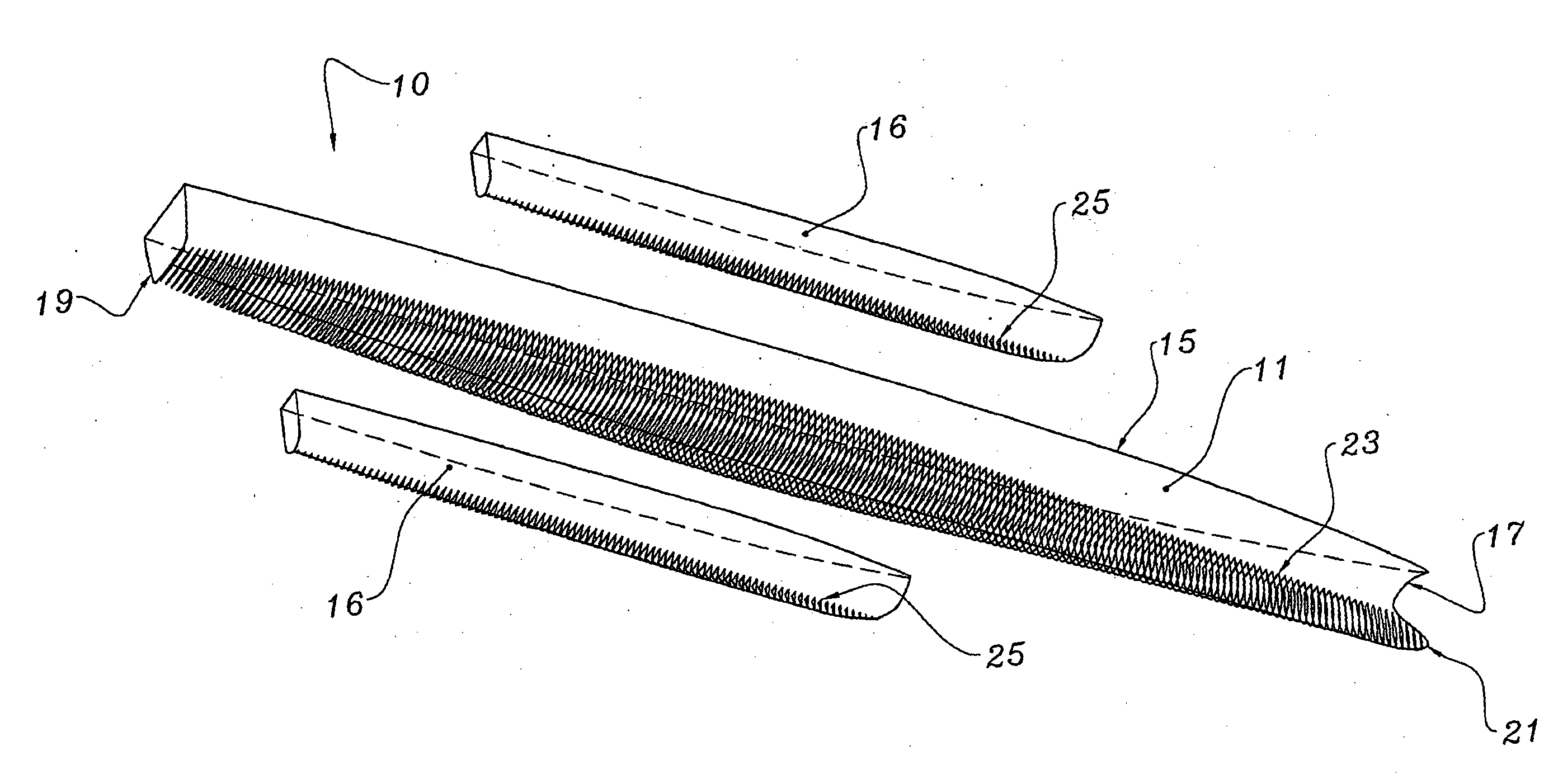

[0035]The embodiment shown in FIGS. 4 and 5 of the drawings is directed to a multi-hulled vessel 10 according to the embodiment. In the arrangement shown, the vessel 10 comprises a three-hulled vessel (being a trimaran) configured as high speed commercial or military vessel, such as a ferry, for passenger and cargo transport, including vehicle transport.

[0036]Typically, the trimaran 10 has a waterline length between 24 metres and 250 metres, although it is of course not limited thereto.

[0037]The triamaran 10 comprises an understructure 11 and a superstructure (not shown), both constructed primarily of aluminium. The waterline in relation to the understructure 11 is identified in FIG. 3 by reference numeral 13.

[0038]The under structure 11 comprises a centrally located main hull 15 and two laterally spaced side hulls 16 commonly known as amahs.

[0039]The main hull 15 has a forward end terminating at a bow 17 and an aft end terminating at a stern 19. The bow 17 may incorporate a forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com