Funnel to counter out-splashing of a fluid being poured through it

a funnel and fluid technology, applied in the field of conventional funnels, can solve the problems of affecting the use of conventional funnels, and requiring slowdown that is not possible or practical, and is difficult to dispose of maintain conventional funnels upright during us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

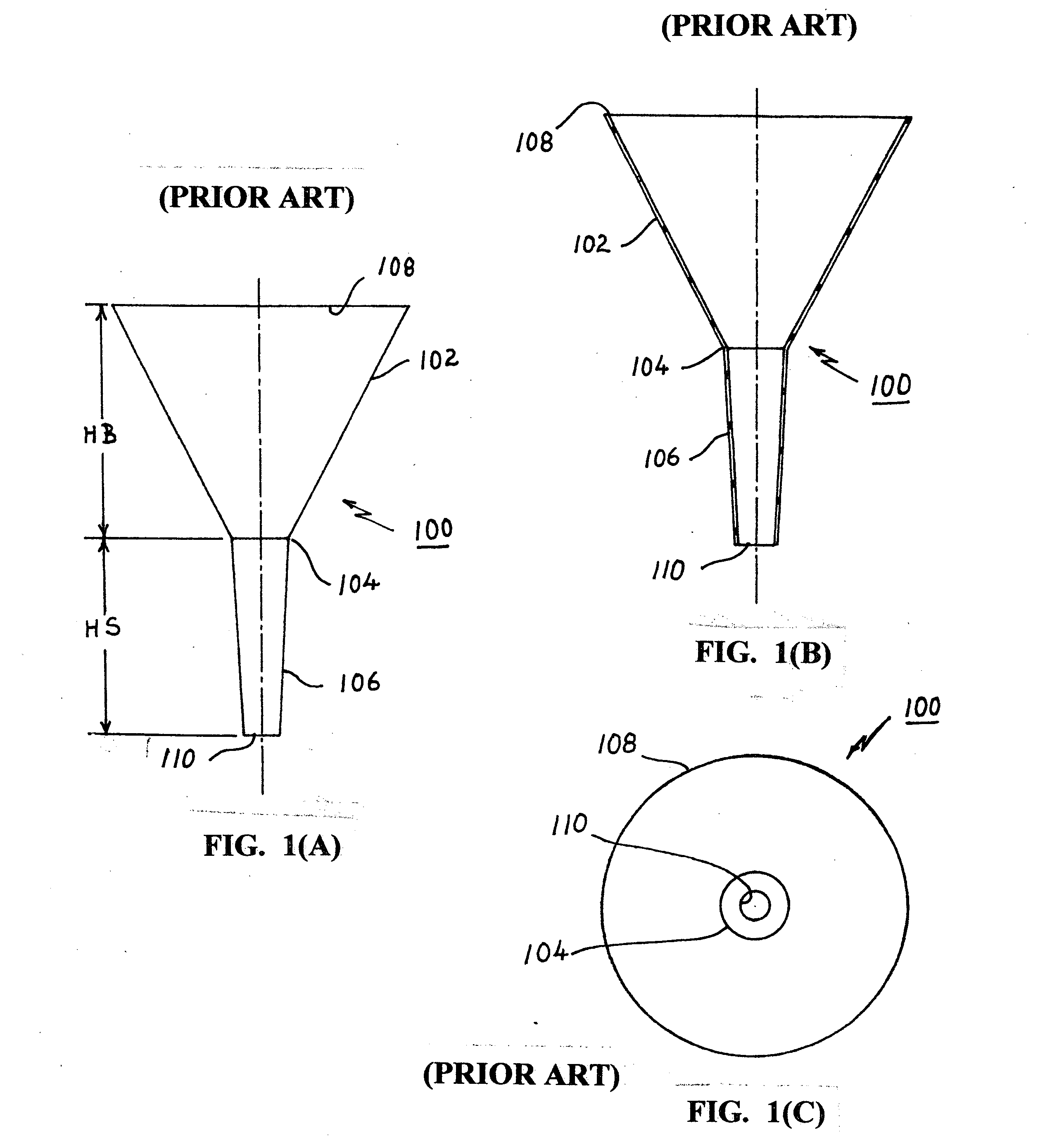

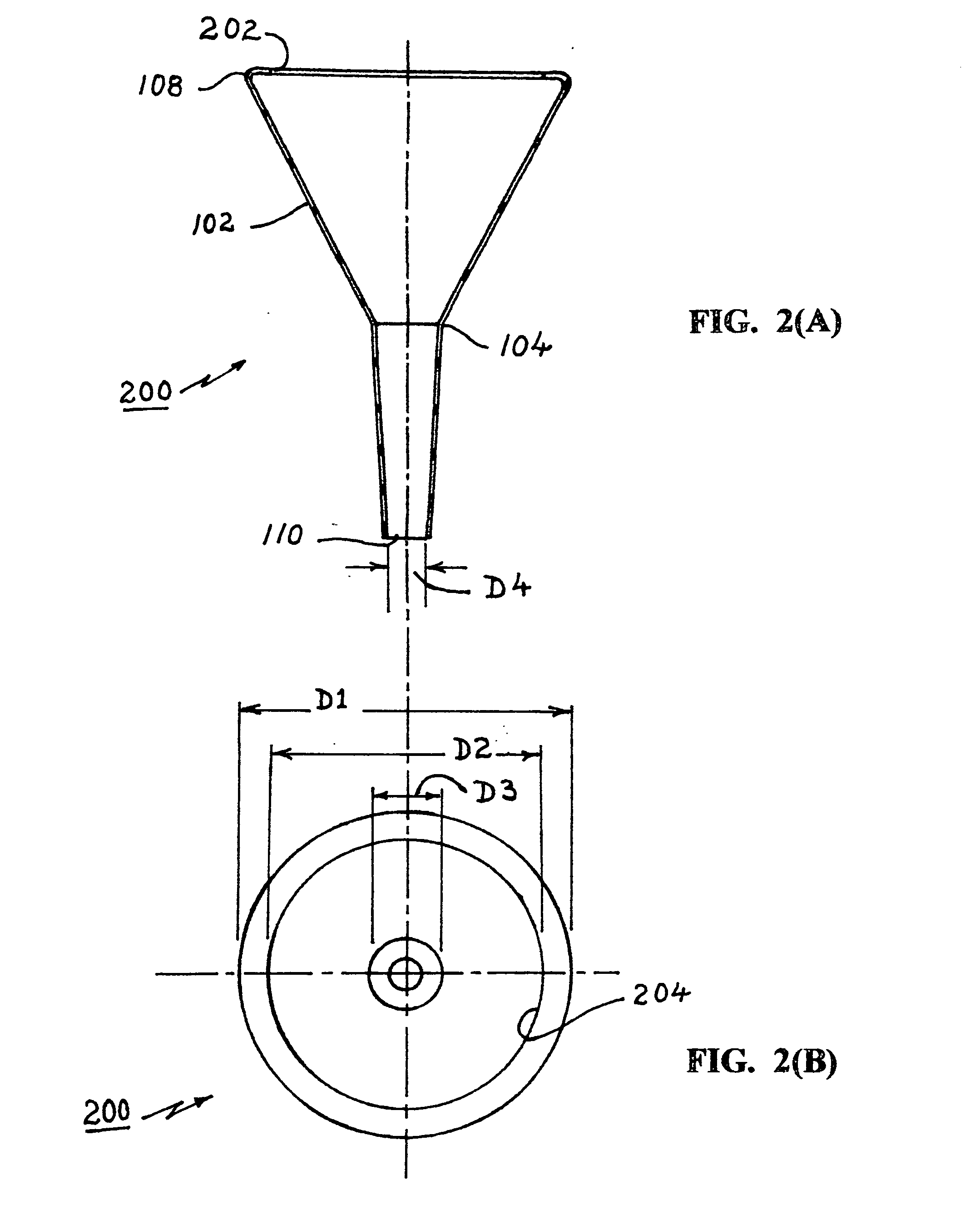

[0048]The improvements presented and claimed below are intended to be selectively applicable, individually or in combination with each other, to funnels of a variety of shapes and sizes, to counter splash-out from them of a variety of fluids—over a wide range of fluid viscosities.

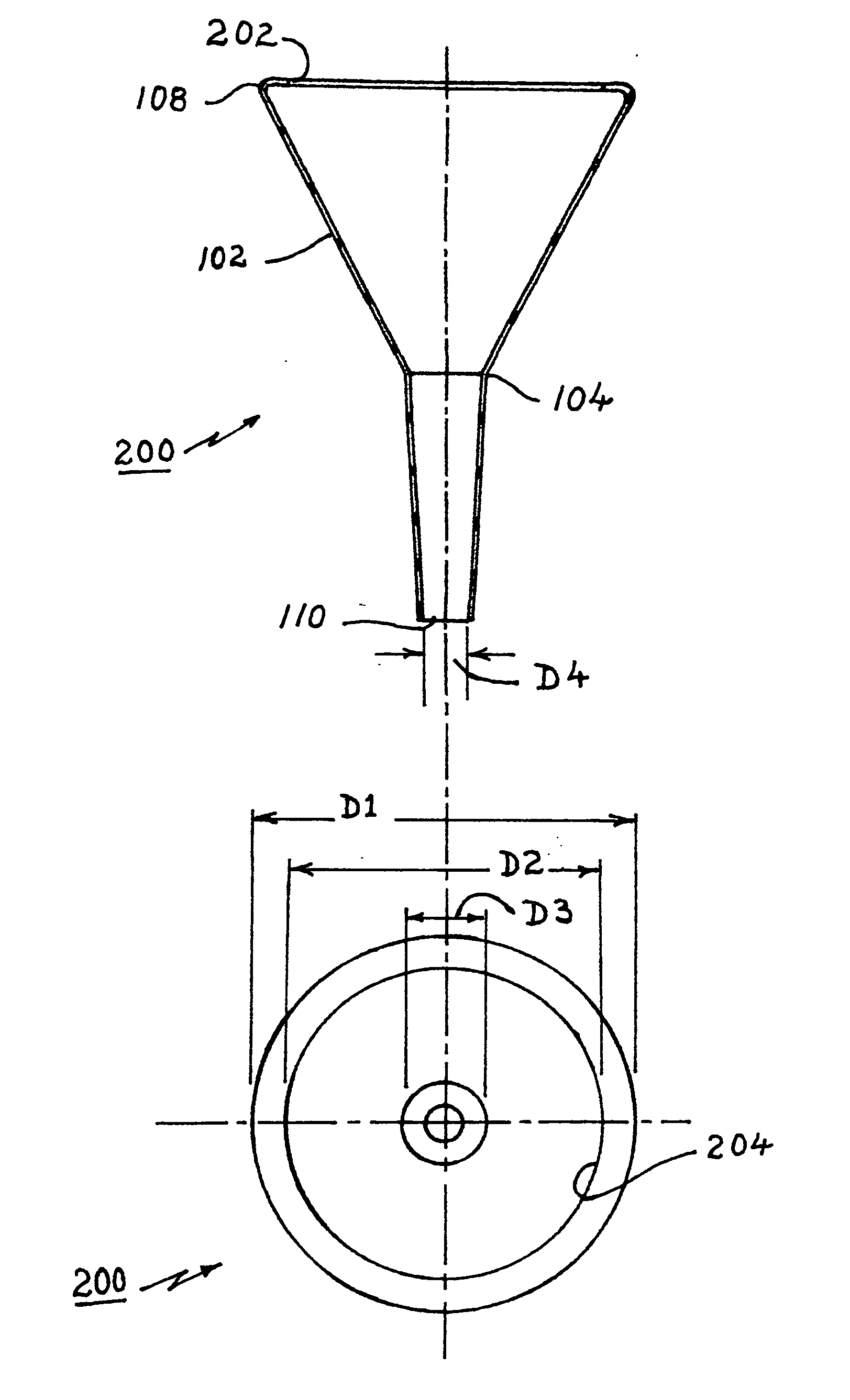

[0049]FIGS. 1(A), 1(B) and 1(C) show elevation, vertical cross-section, and top plan views, respectively, of a known portable funnel of a kind used for the transfer of fluids like milk, syrup, paint, motor oil, anti-freeze, transmission fluid, and the like. Such funnels, while not expensive, are not normally considered disposable and are often cleaned after each use and stored for future use. Non-disposable metal funnels, of the same general shape but generally somewhat larger, also are often used for similar but more substantial fluid transfers. Glass funnels of the same basic shape are often used in laboratories that handle highly reactive acids and / or other poisonous fluids.

[0050]Funnel 100 per FIGS. 1(A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com