Barrel rack

a barrel rack and rack technology, applied in the field of barrel racks, can solve the problems of difficult cleaning, damage to the barrel, and unsuitable storage of barrels, and achieve the effect of economic construction and high adaptability to storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

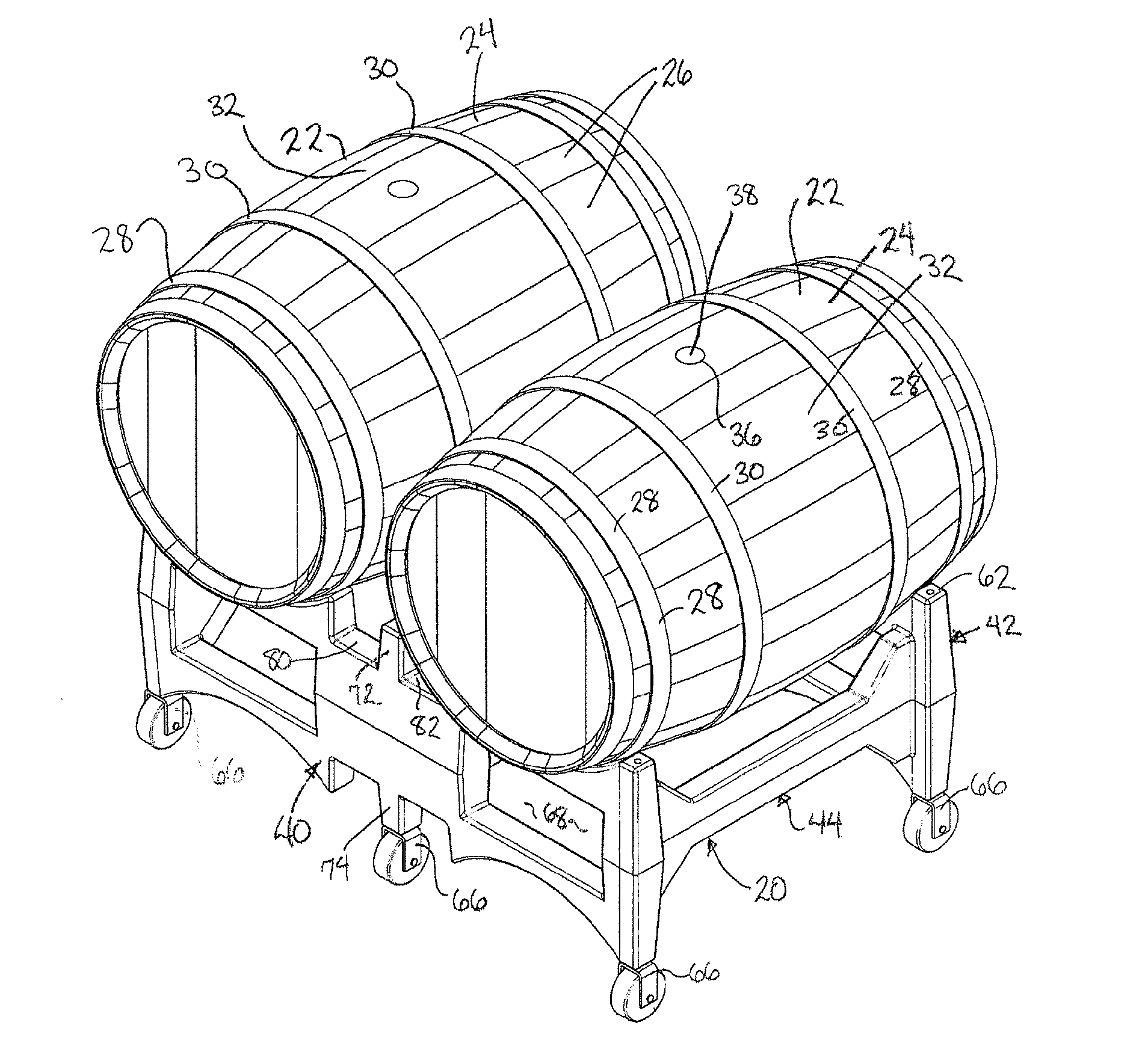

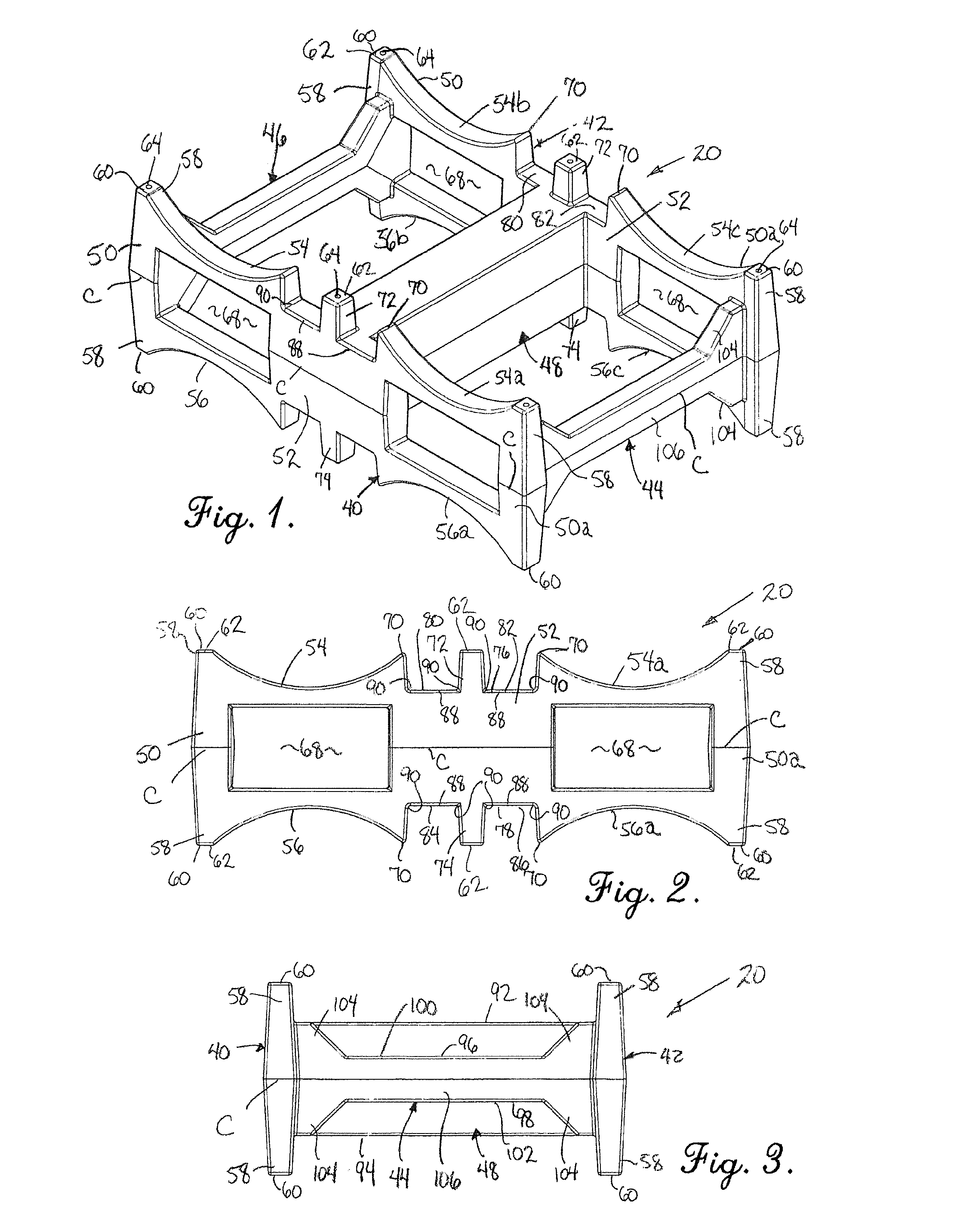

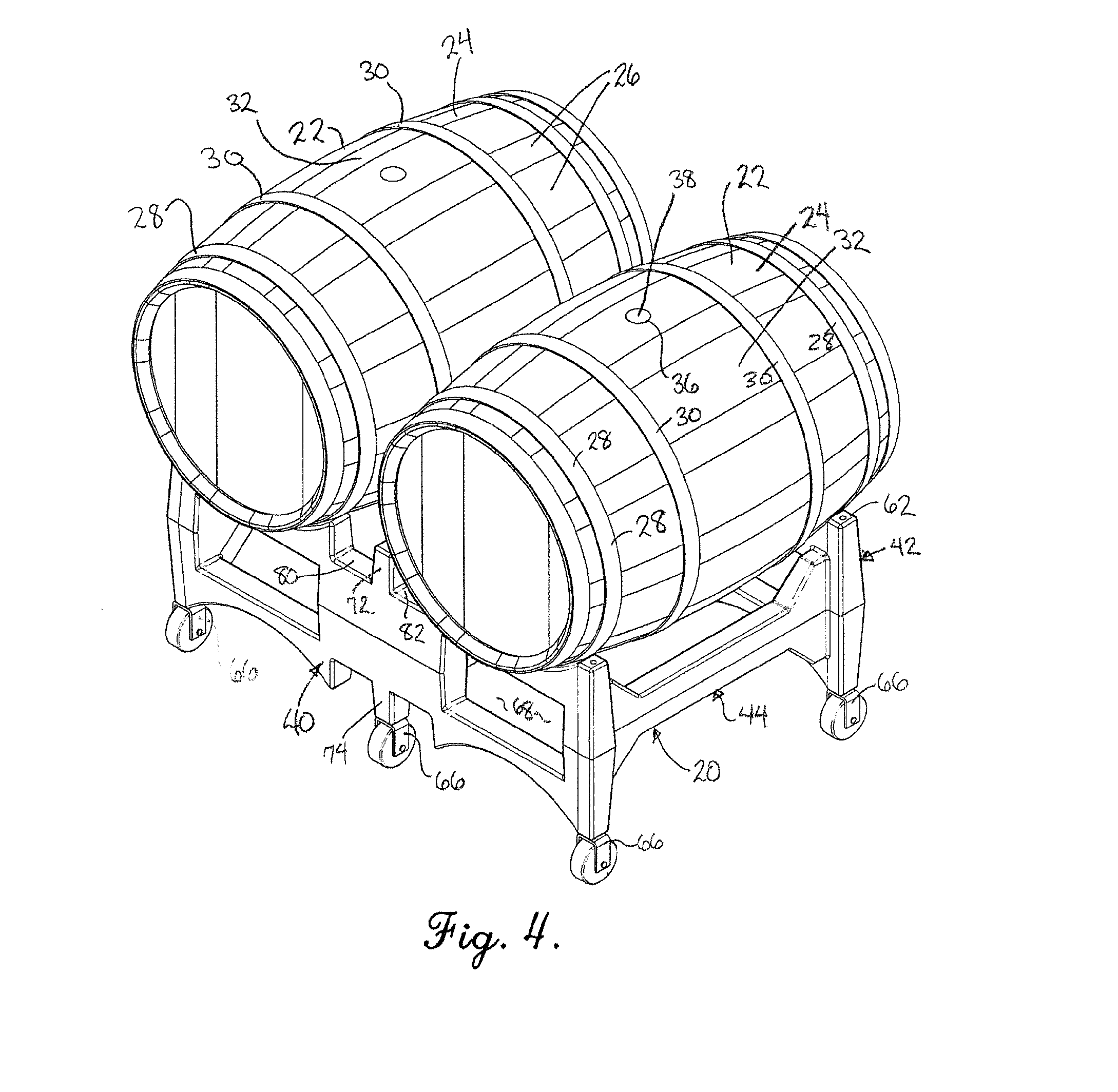

[0042]Referring now to the drawings, a barrel rack 20 may be advantageously rotationally molded in a unitary, symmetrical configuration of synthetic resin such as high density polyethylene (HDPE) as a single, one-piece unit and configured to receive one or a plurality of barrels 22. The barrel rack 20 as shown in the drawing is configured for receiving two barrels 22 thereon, but could also be constructed in an elongated configuration for receiving three, four or more barrels as will be appreciated by those skilled in the art. The barrels 22 may be of different shapes and sizes (e.g. 30 gal., 50 gal., 59 gal. or other sizes) and the dimensions of the barrel rack 20 when molded maybe changed so as to advantageously receive and retain a barrel of a selected size.

[0043]Barrels 22 typically stored on the barrel rack 20 may be of different materials or configurations, but most typically would be barrels 22 used for storing wine, spirits or the like. Such barrels 22 are traditionally made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com