Method and apparatus in a pneumatic material conveying system, and a waste conveying system

a conveying system and waste technology, applied in the field of pneumatic material conveying systems, to achieve the effect of efficient distribution, reliable operation, and effective dimensioning and cost of the drive device of the conveying devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

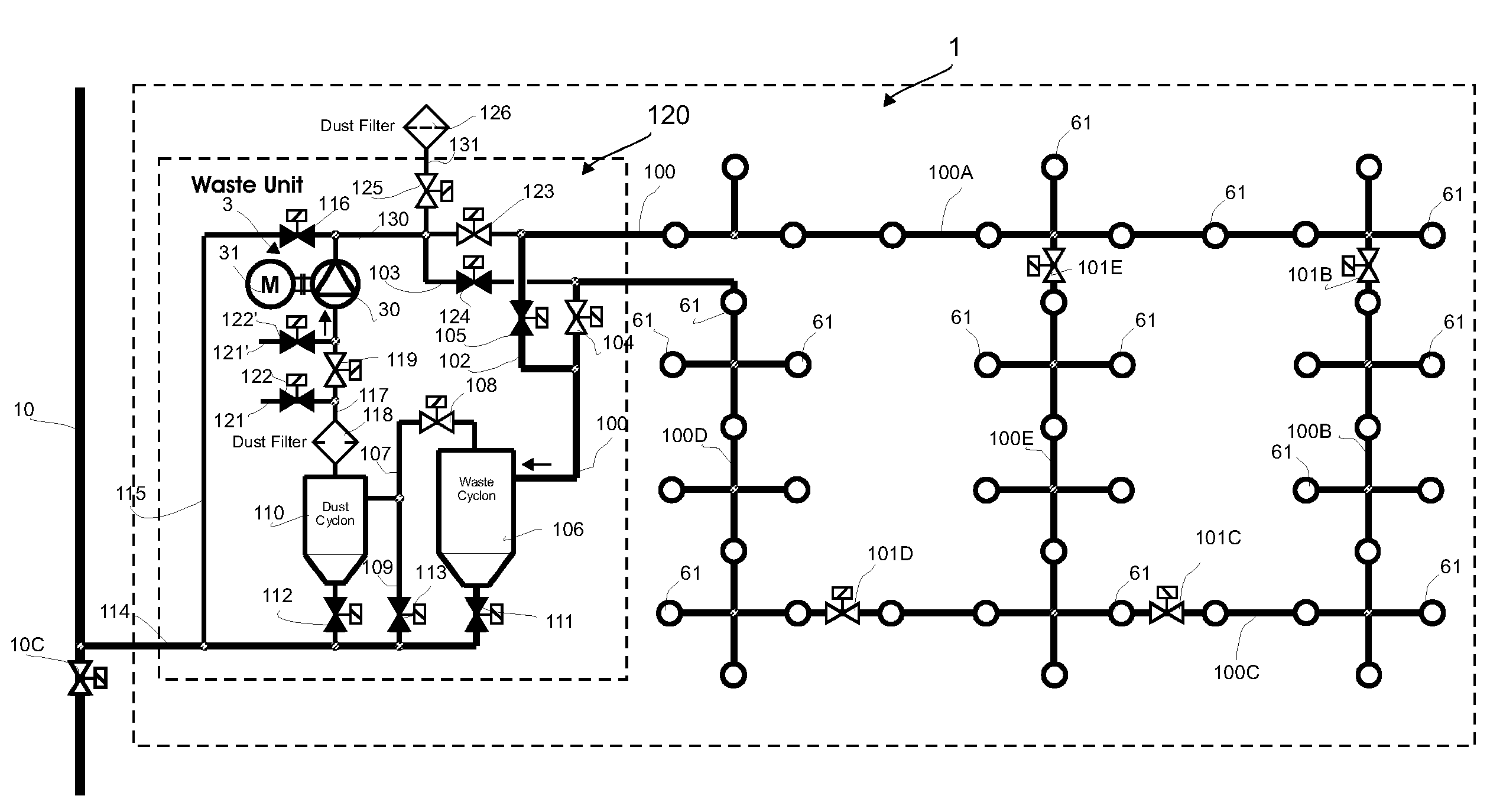

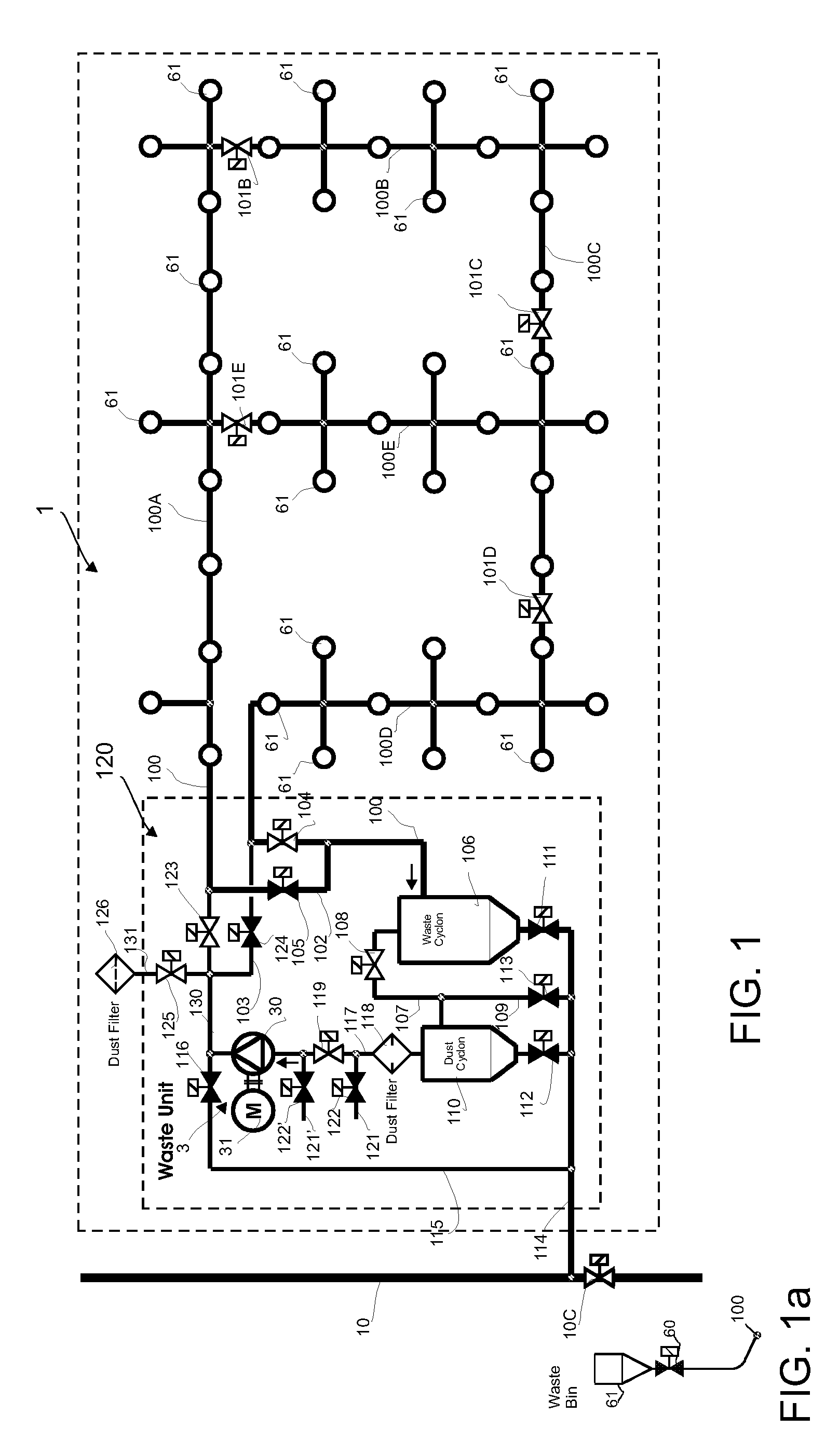

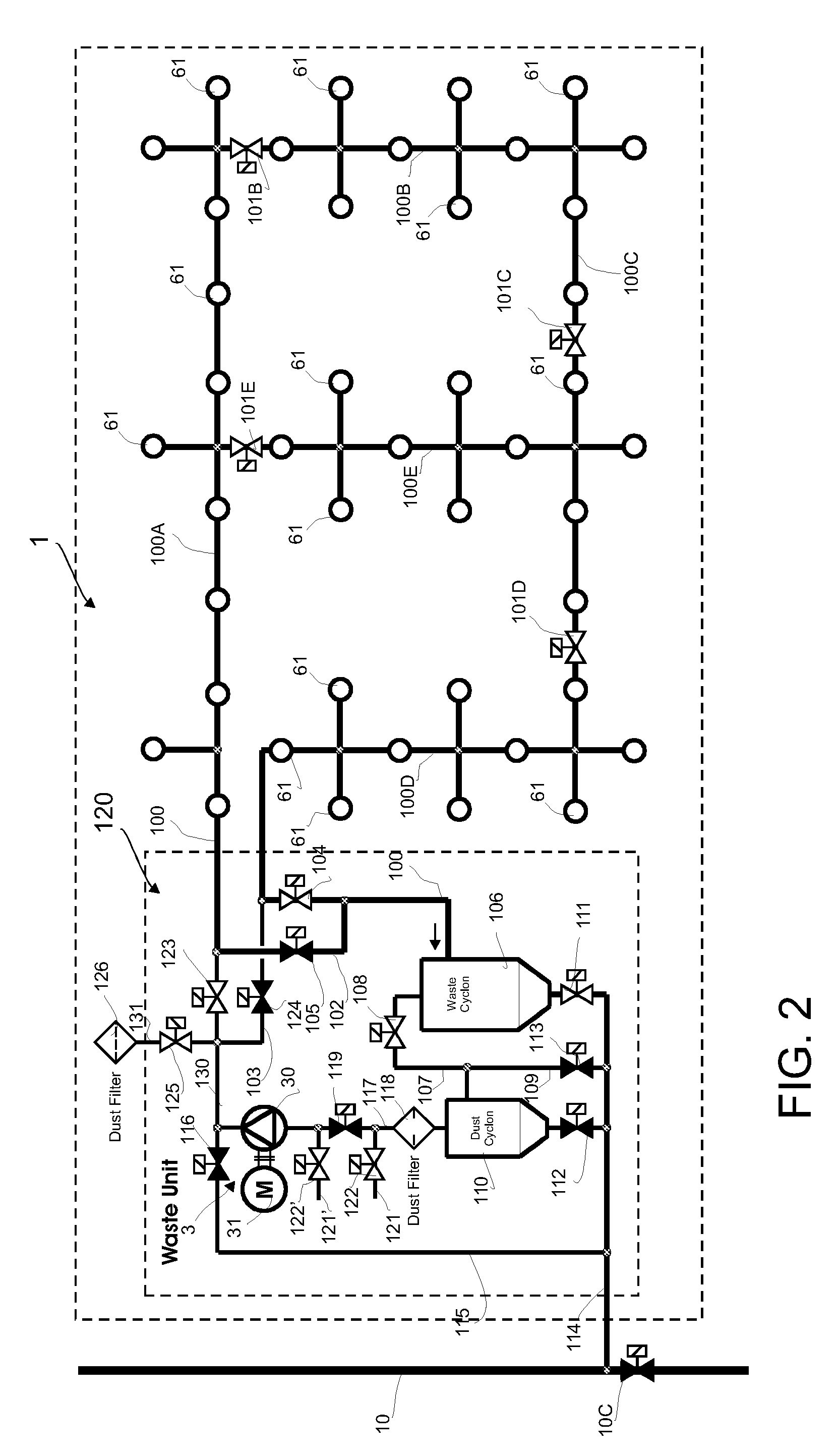

[0031]FIGS. 1-6 present the operation of a subsystem 1 of a material conveying system according to the invention, in different operating phases. FIG. 7 presents the total system, which comprises five subsystems 1 (I, II, III, IV, V) and also a waste station 2 and the necessary conveying piping 10, 11, 12, 114 between the subsystems 1 (I, II, III, IV, V) and the waste station 2.

[0032]FIG. 1 presents a subsystem 1, which comprises a material conveying pipe 100, along the side of which at least one, typically many, input points 61 are arranged. An input point 61 is a feed-in station of material, more particularly of waste material, intended to be conveyed, from which station the material, more particularly waste material, such as household waste, intended to be conveyed is fed into the conveying system. The feed-in station 61 can also be a refuse chute, into which material is fed from input apertures on different floors of a building. The system can comprise a number of feed-in station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com