Process for Removing Carbon Dioxide From a Gas Stream using Desublimation

a technology of carbon dioxide and gas stream, which is applied in the direction of separation processes, liquefaction, lighting and heating apparatus, etc., can solve the problems of significant additional investment and operating costs of industrial plants, increase of electricity costs in the range of 4 to 5 u.s. cents/kwh, and equipment addition, etc., to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

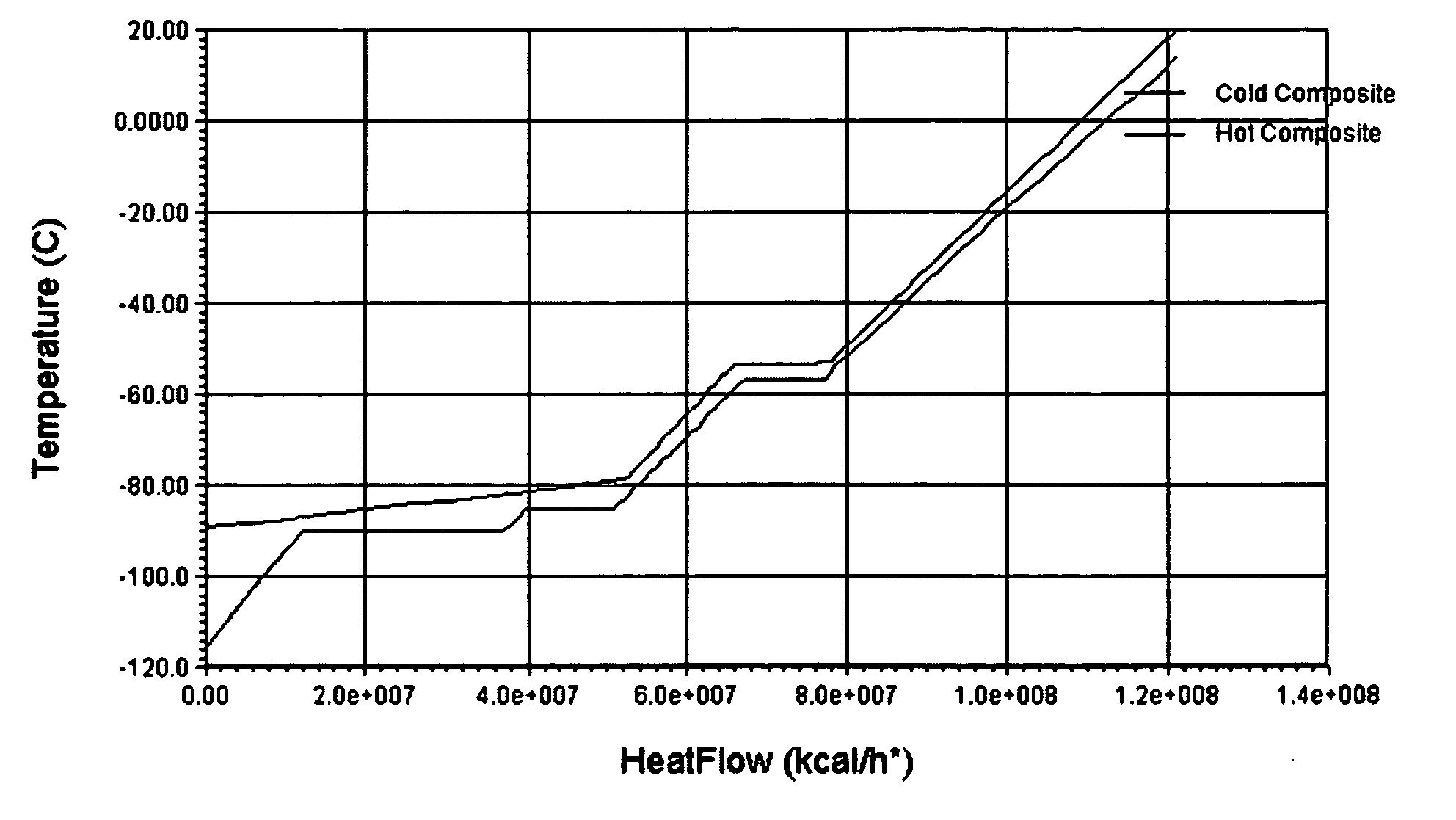

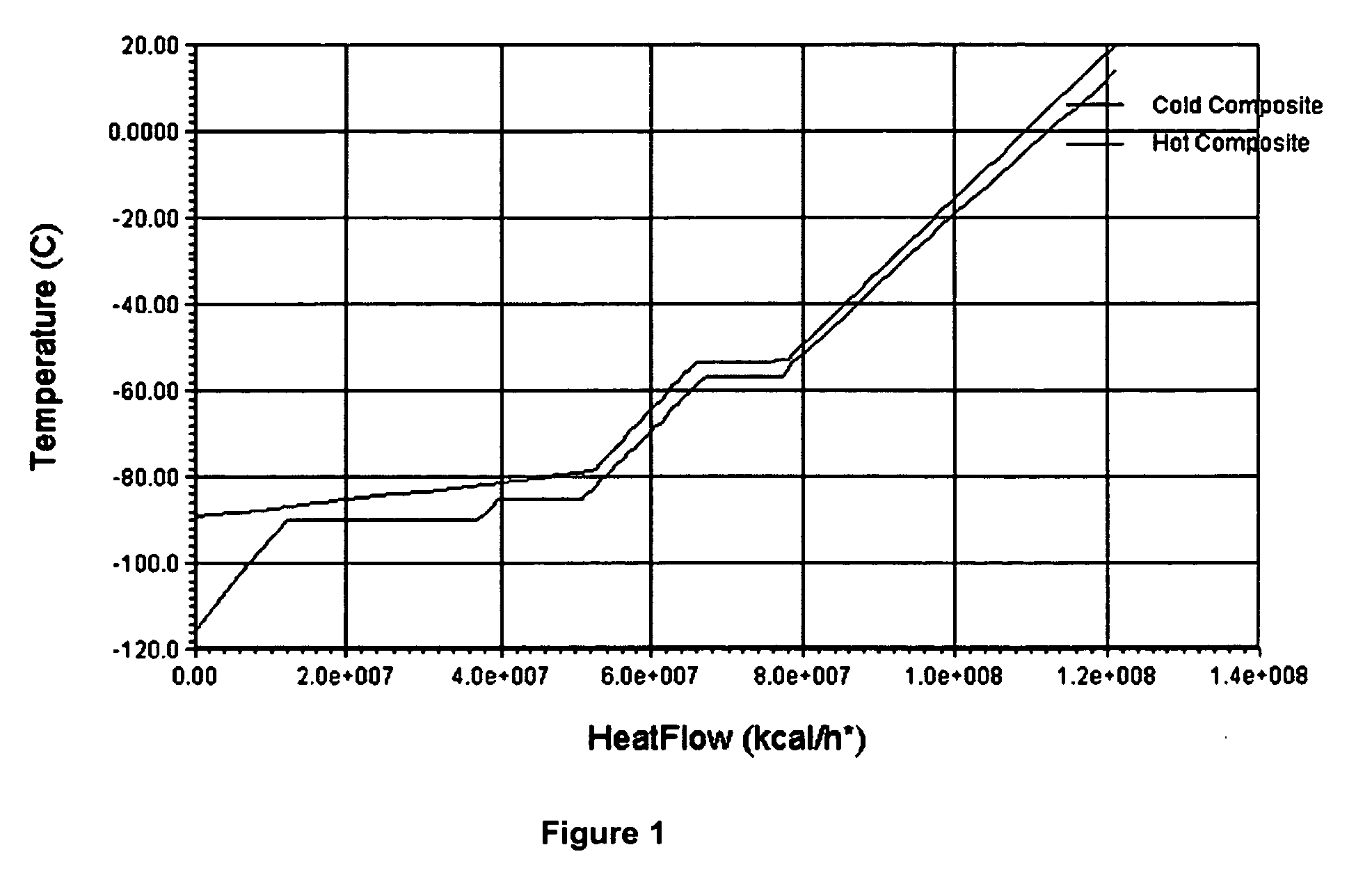

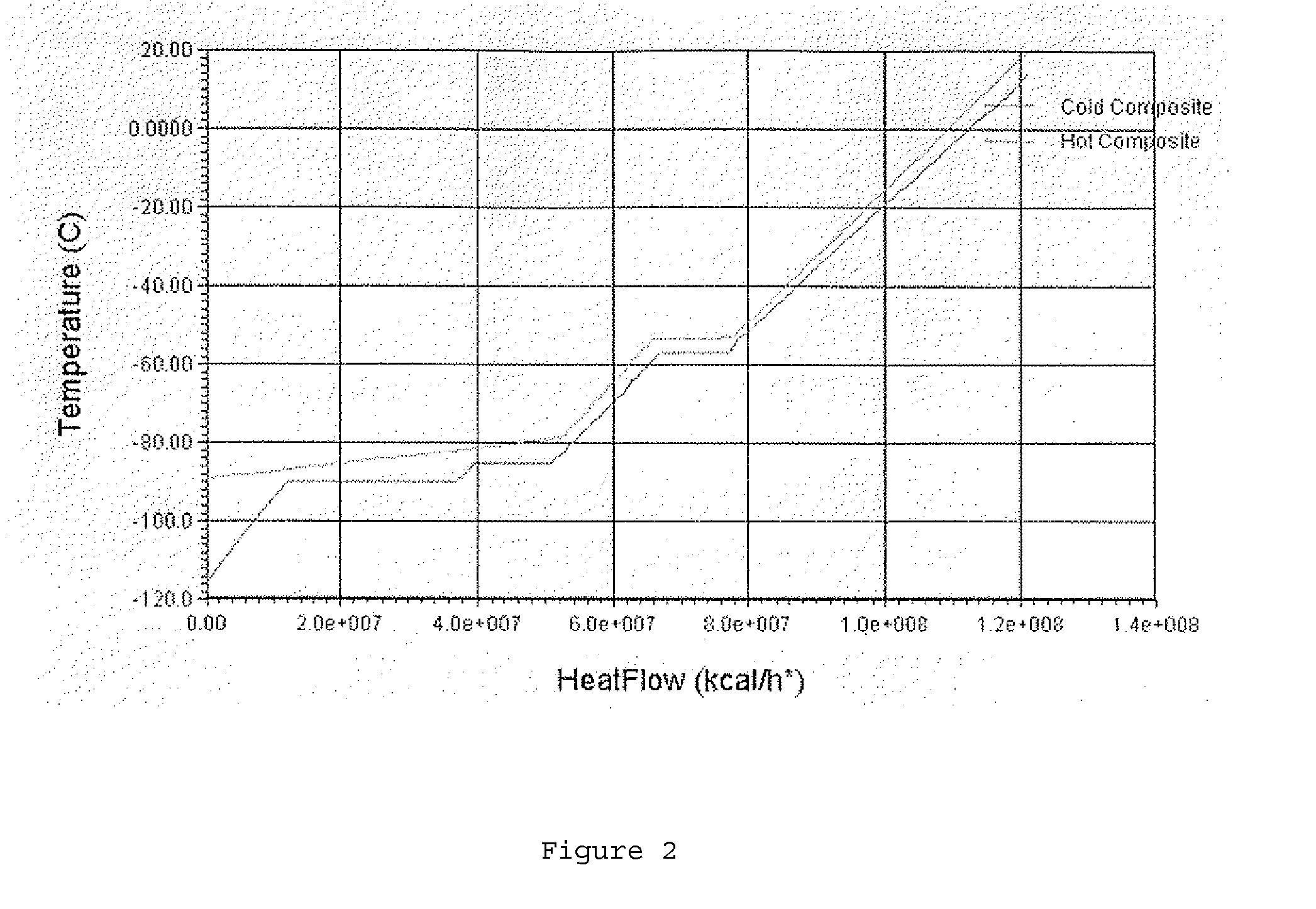

Image

Examples

Embodiment Construction

[0033]The present process relates to a more efficient process for the removal of carbon dioxide from a carbon dioxide containing stream. By capturing the energy associated with the transition of solid carbon dioxide to either a liquid or vapor, it is possible to eliminate or at least significantly minimize the use of the external cooling systems such as additional refrigerant loops including compressors as well as the cooling means for compressed refrigerant that have previously been used in the prior art systems of carbon dioxide removal. The process may be carried out in a direct manner in which the use of the prior art external cooling systems are eliminated or in an indirect manner in which the prior art external cooling systems are minimized (used only to bolster the process).

[0034]With regard to the carbon dioxide containing gas streams that may be treated utilizing either embodiment of the present invention, such streams may be provided from a variety of sources, including bu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap