Nuclear reactor refueling methods and apparatuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

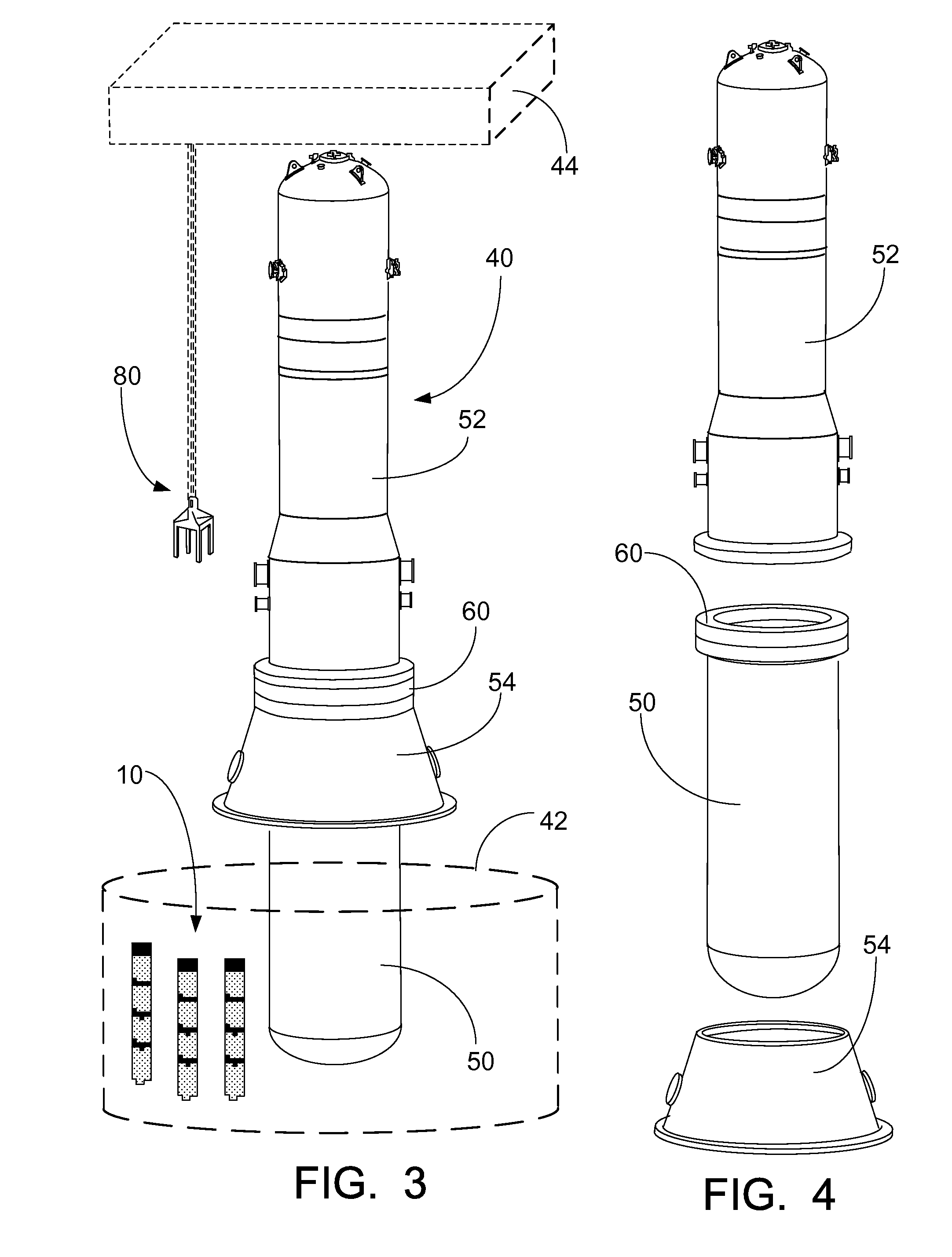

[0026]With reference to FIGS. 3-5, an illustrative nuclear reactor is shown. FIG. 3 shows the nuclear reactor 40 in conjunction with a diagrammatically indicated spent fuel pool 42 and a diagrammatically indicated crane 44. FIG. 4 shows an exploded view of the pressure vessel of the nuclear reactor of FIG. 3. The pressure vessel includes a lower vessel portion 50, an upper vessel portion 52, and a skirt or support structure 54. In the illustrative arrangement, the pressure vessel is mounted vertically (as shown) with at least part of the lower vessel portion 50 disposed below ground level. The bottom of the skirt or support structure 54 is at ground level and supports the pressure vessel and / or biases the pressure vessel against tipping. In the illustrative example of FIG. 3, the spent fuel pool 42 is a below-ground pool containing water and optional additives such as, by way of illustrative example, boric acid (a soluble neutron poison). FIG. 5 shows an exploded perspective view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com