Payload delivery system with forward folding stabilizer for cartridges

a cartridge and forward folding technology, applied in the field of cartridges, can solve the problems of difficult manufacturing of these components and cartridges themselves, more complex payloads that require additional complex and expensive components, and the cost of construction, tooling, and tooling, etc., and achieve the effect of precise position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

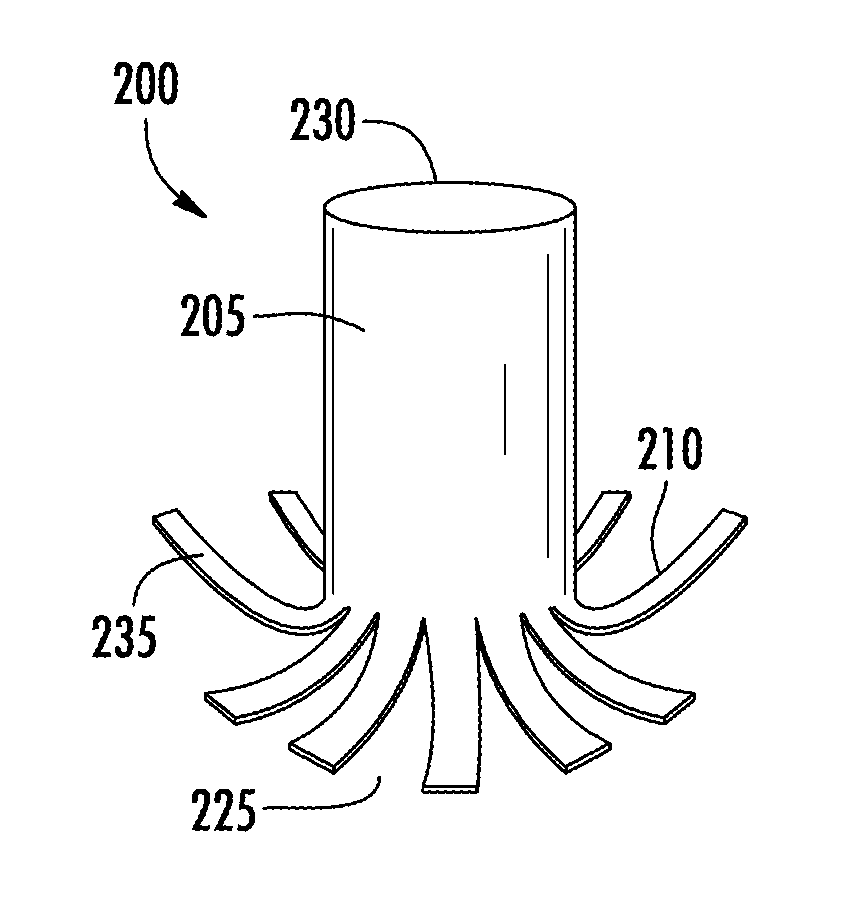

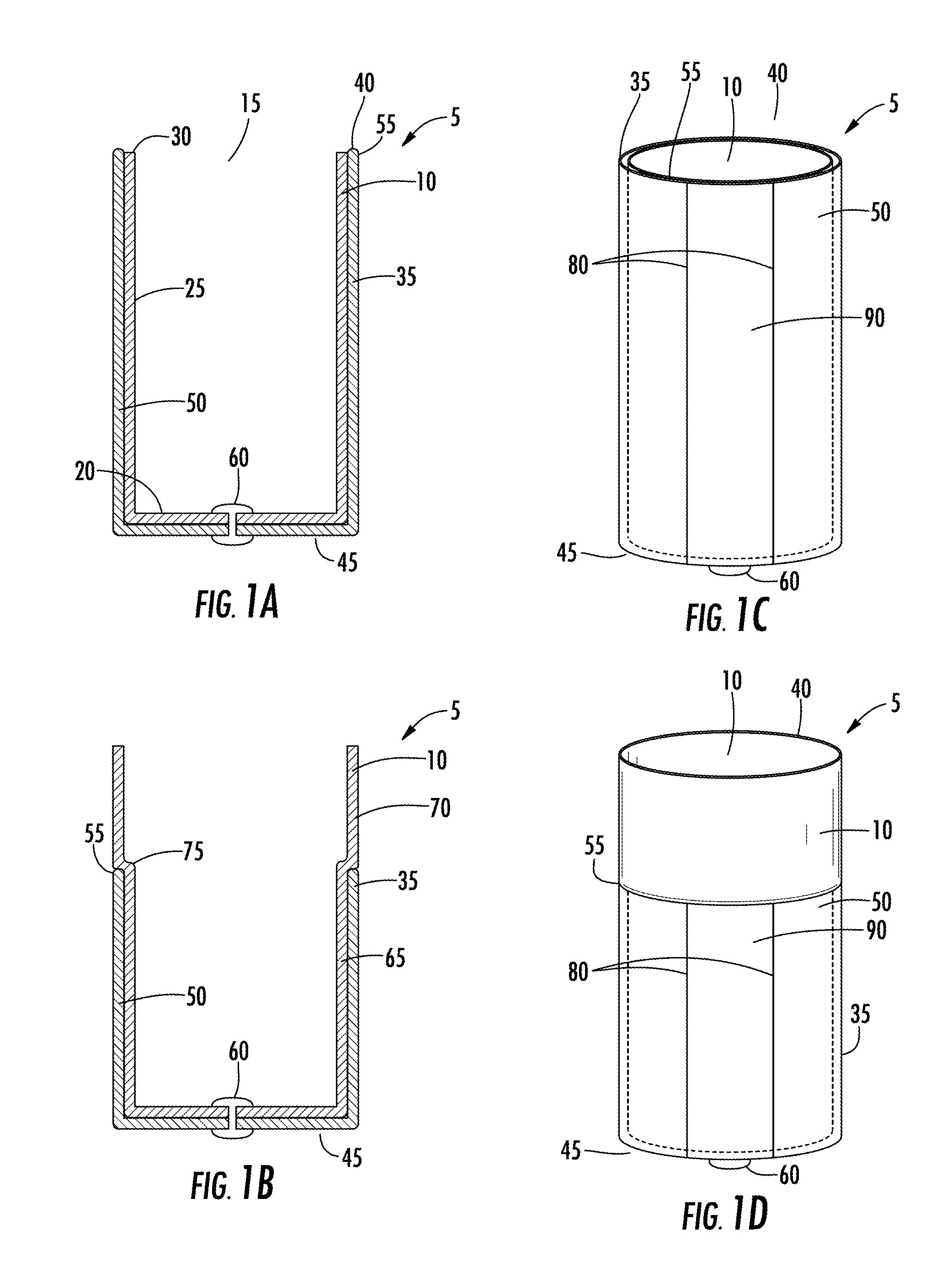

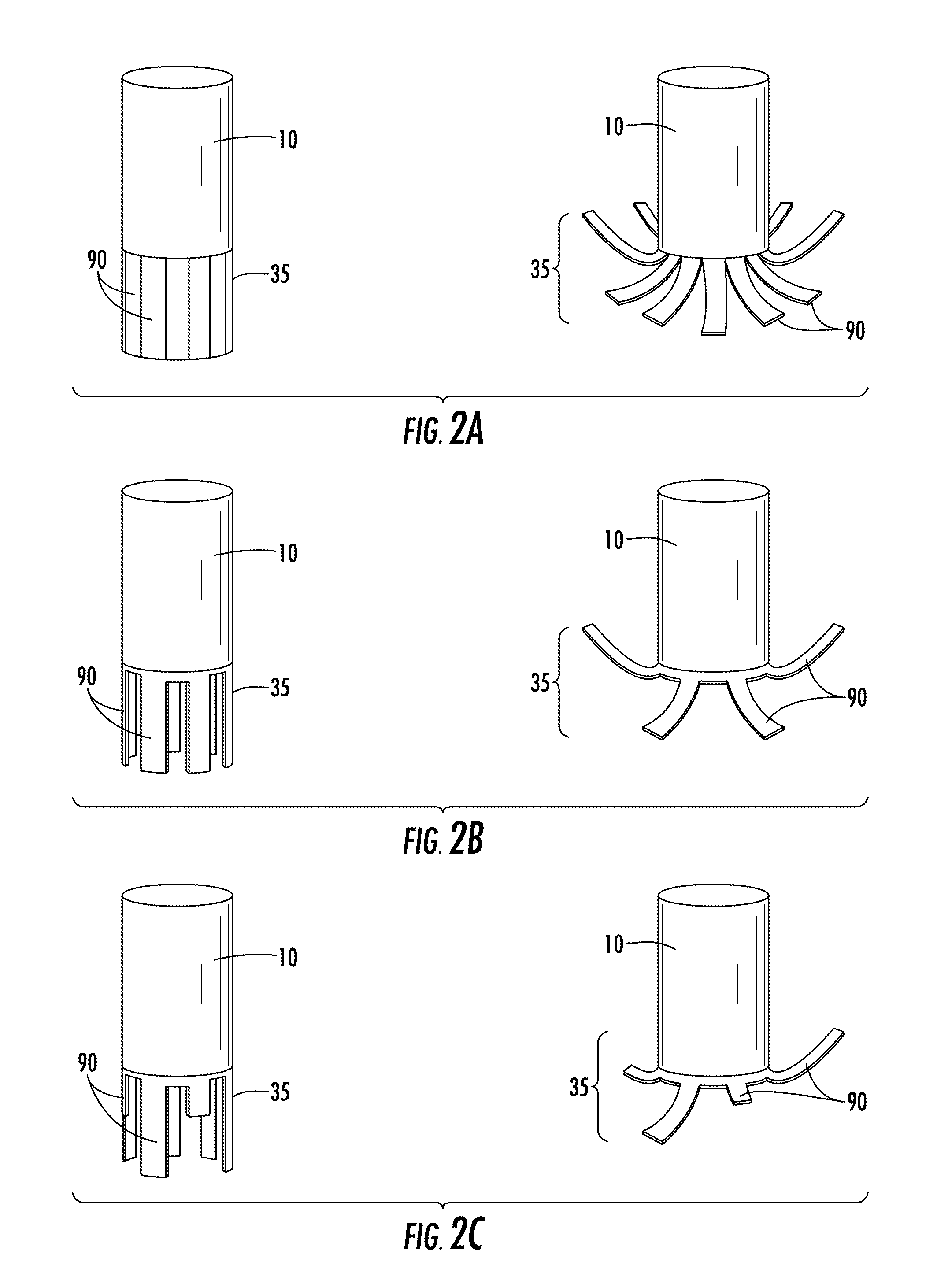

[0062]This disclosure provides for a payload delivery system for use in cartridges or launched in any fashion, the system including a cup-shaped stabilizer that assists in the discharge, launching, and ballistic performance of the payload. In some aspects, the stabilizer can serve as a flight stabilizer for any payload or payload cup to which it is attached. If desired and in some embodiments, other components such as spacers can be used along with the projectiles and the stabilizer. The cup-shaped stabilizer can be adjusted to achieve different degrees of drag for a desired ballistic performance. In other aspects, the cup-shaped stabilizer can contain the payload in its own cavity and function as its own type of payload container or payload cup. In this aspect, after a certain distance downrange, the stabilizer can open and peel back to cleanly separate from its payload. The potential advantages of this payload delivery system include using relatively low-cost components, avoiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com