Convertible dishwasher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

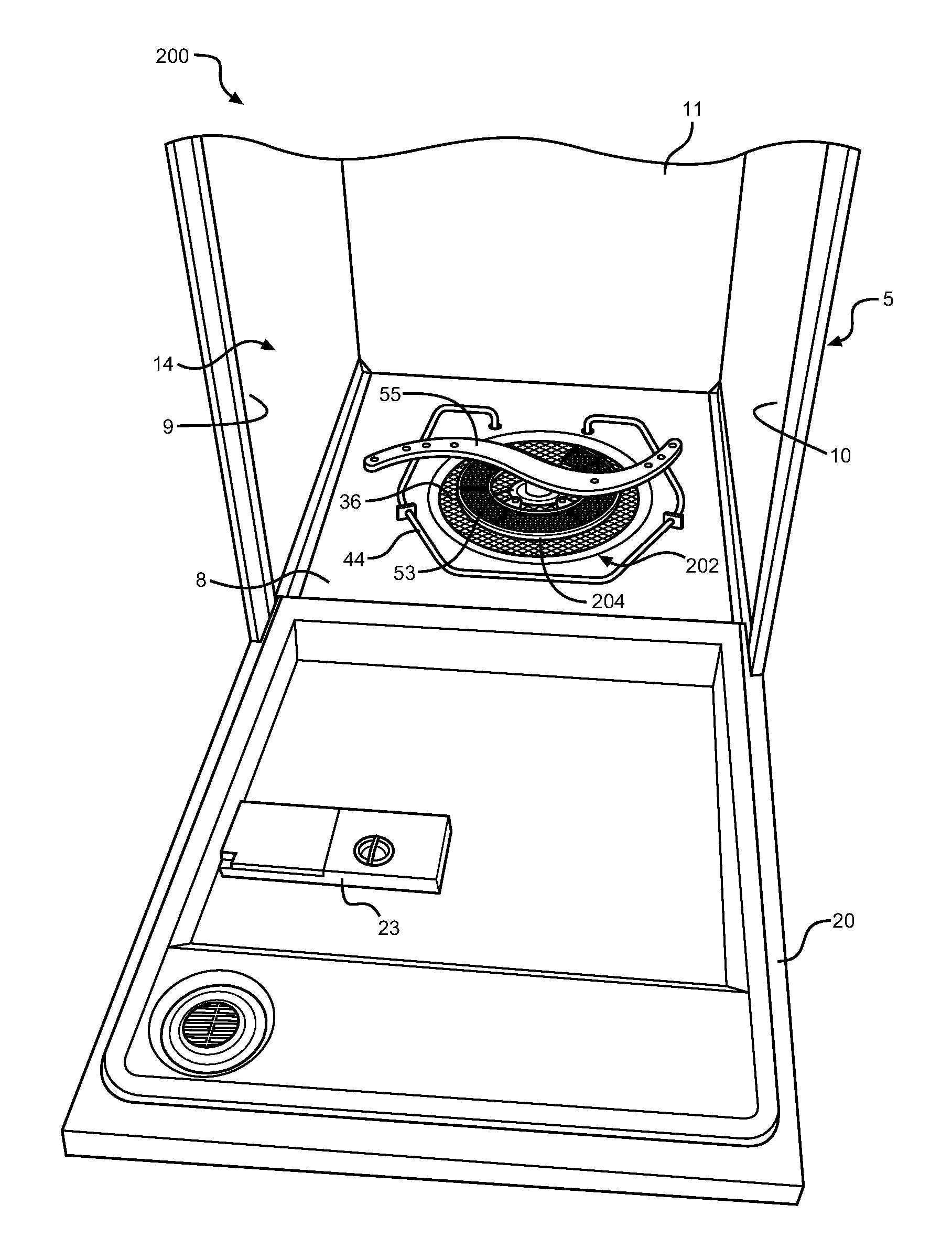

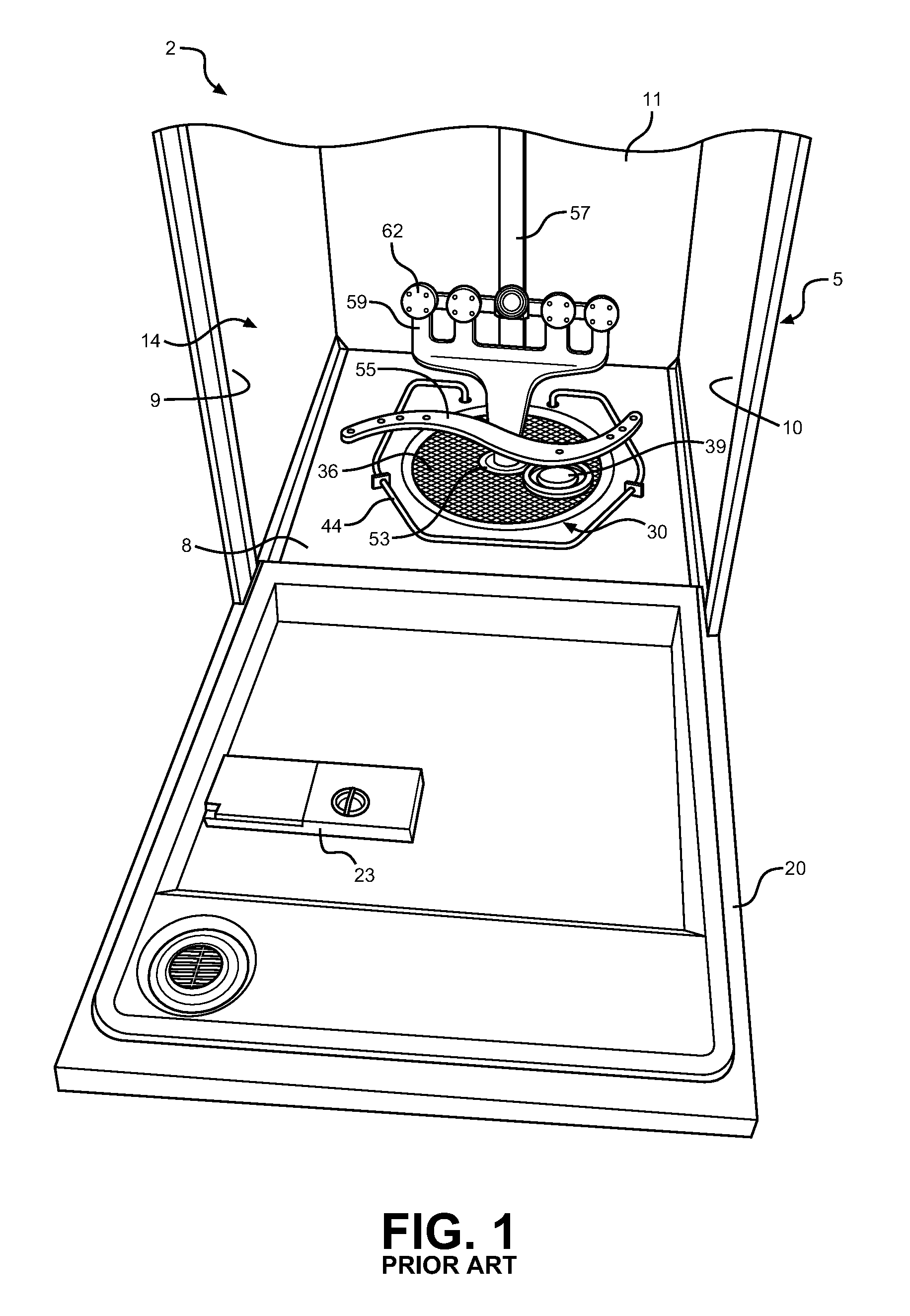

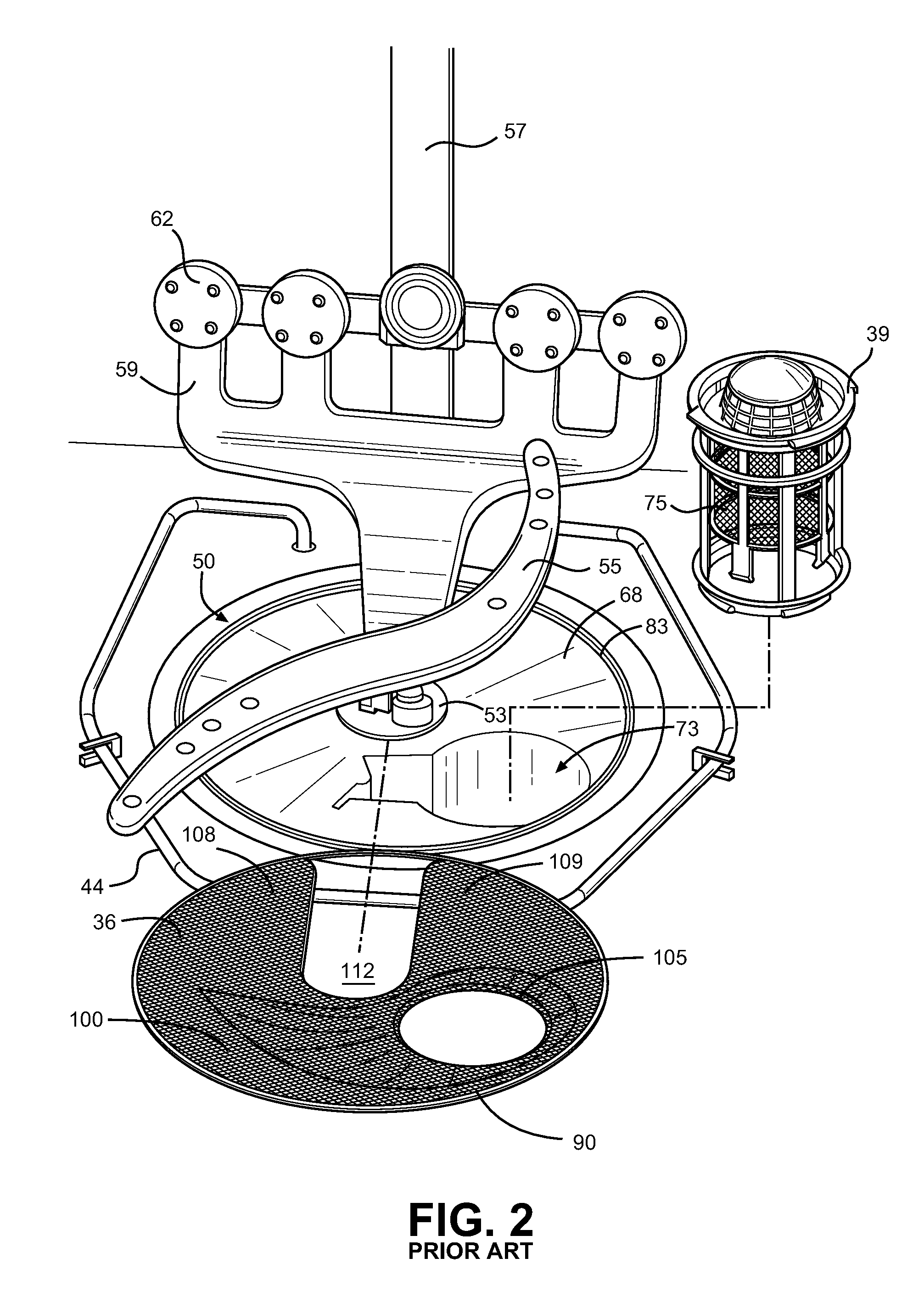

[0024]The manner in which washing fluid is channeled to a drainage pump 230 and recirculation pump 213 will now be discussed with reference to FIG. 7. In a first embodiment, filtration system 202 is utilized in a chopping type dishwashing arrangement. In use, washing fluid flowing into sump unit 50 during the dishwashing cycle will flow by gravity through central main strainer 36′ into recessed main intake 73. Central main strainer 36′ acts as a coarse particle strainer to prevent coarse particles from entering recessed main intake 73. However, washing fluid flowing into recessed main intake 73 may carry fine particles which are carried with the washing fluid into recirculation intake port 80 to a recirculation pump inlet generally indicated at 232 and to a chopper assembly 233. In a manner known in the art, chopper assembly 233 macerates particles entrained within washing fluid to be recirculated to fluid supply hub 206 by recirculation pump 213. Various types of chopping mechanism...

second embodiment

[0027]In a second embodiment, filtration system 202 is utilized in a filtration only dishwashing arrangement. More specifically, when a filtration with accumulator only dishwashing arrangement is desired, accumulator 204 and check valve cover 210 are inserted into recessed main intake 73 in the manner described above, followed by, or as part of, fine filter 212. See FIG. 7. Preferably, bottom wall 212a of fine filter 212 mounts or is otherwise secured to check valve cover 210, and top wall 212b of fine filter 212 extends to accumulator 204 or up to filter screen 36, such that fluid entering upper fluid recirculation chamber 254 from tub 5 is filtered by fine filter 212 before entering recirculation pump inlet 232. In the embodiment shown in FIG. 7, bottom wall 212a of fine filter 212 fits within a filter receiving aperture 257 within check valve cover 210 to secure fine filter 212 to check valve cover 210. However, fine filter 212 could also be made part of check valve cover 210. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com