Beverage filter cartridge

a technology for filter cartridges and beverages, applied in the field of beverage filter cartridges, can solve the problems of poor flow of brewed liquid, insufficient volume of single serving cartridges, and insufficient volume of ground coffee, and achieve the effects of less non-biodegradable waste, enhanced stability, and stabilized caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

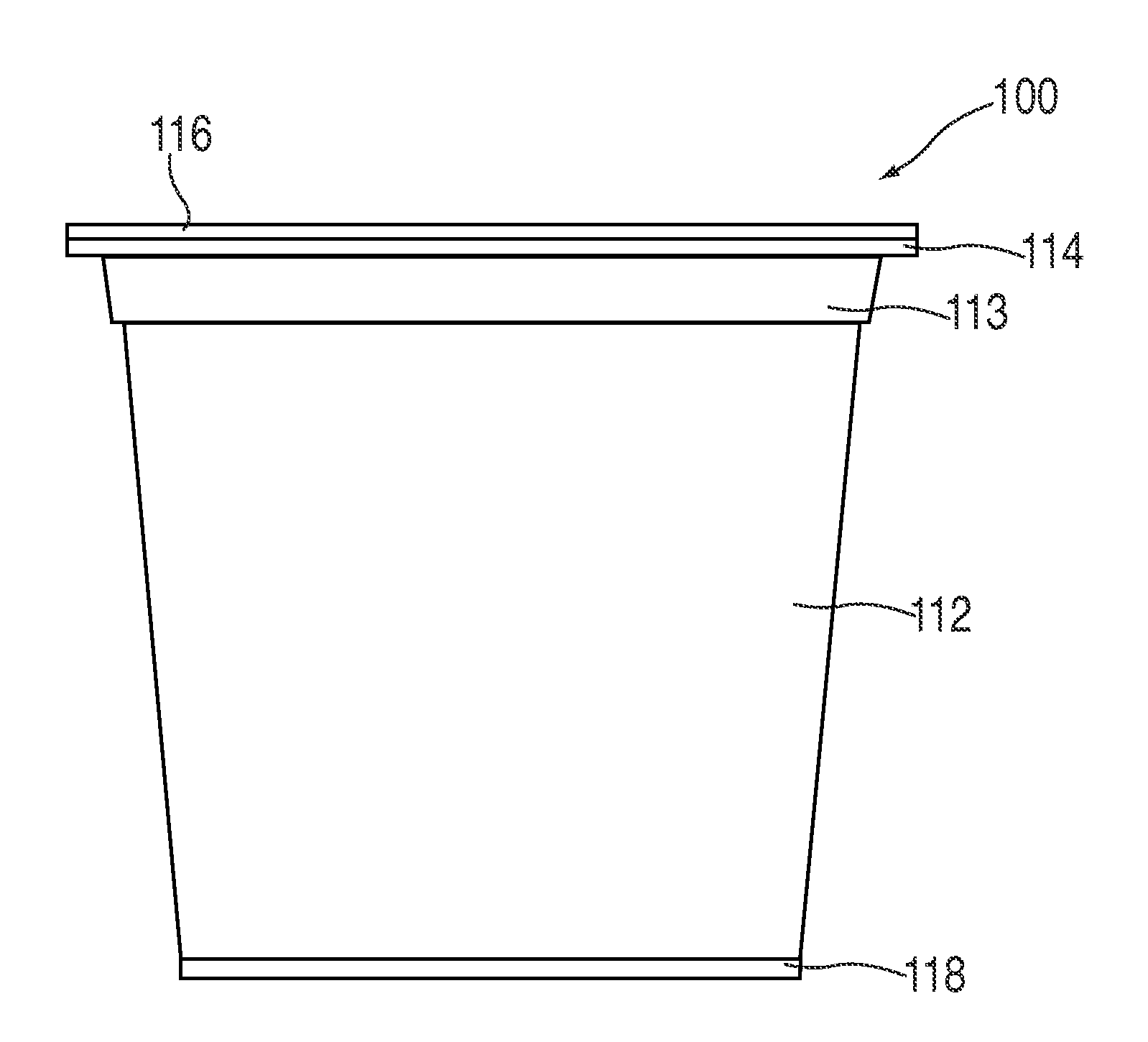

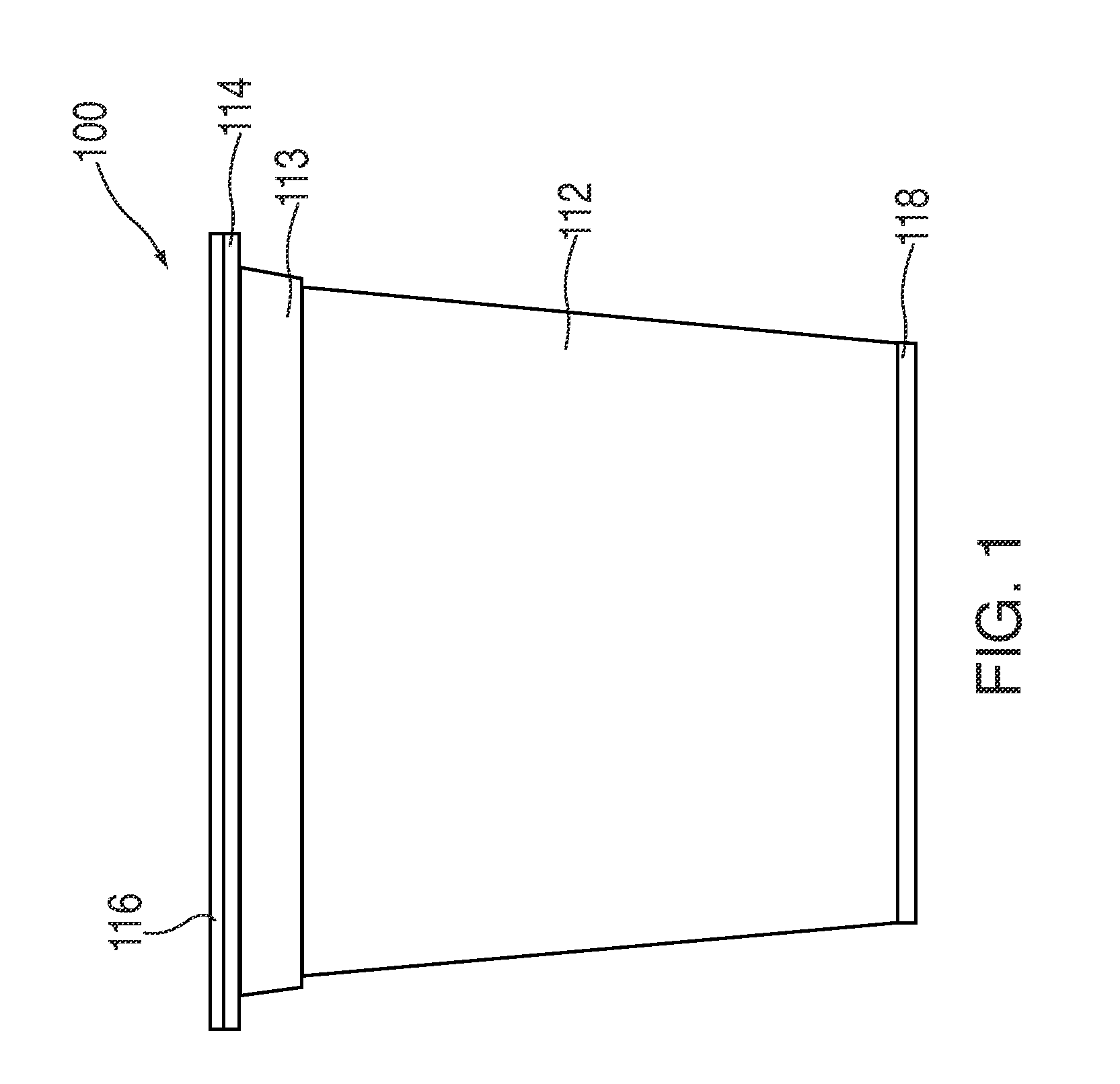

[0043]Reference is made to FIGS. 1-7, wherein the single serving beverage container, generally indicated as 100, constructed in accordance with a preferred embodiment of the invention, is depicted. As seen in FIG. 1, beverage cartridge 100 includes central body 112, upper flange 114, top number 116 and bottom cover 118. In the current preferred embodiment the top cover 116 and the bottom cover 118 are oxygen impermeable layers which can be made either of foil or plastic layers which seal to the flange 114 at the top of body 112 and to the bottom of body 112 as shown more particularly in other views.

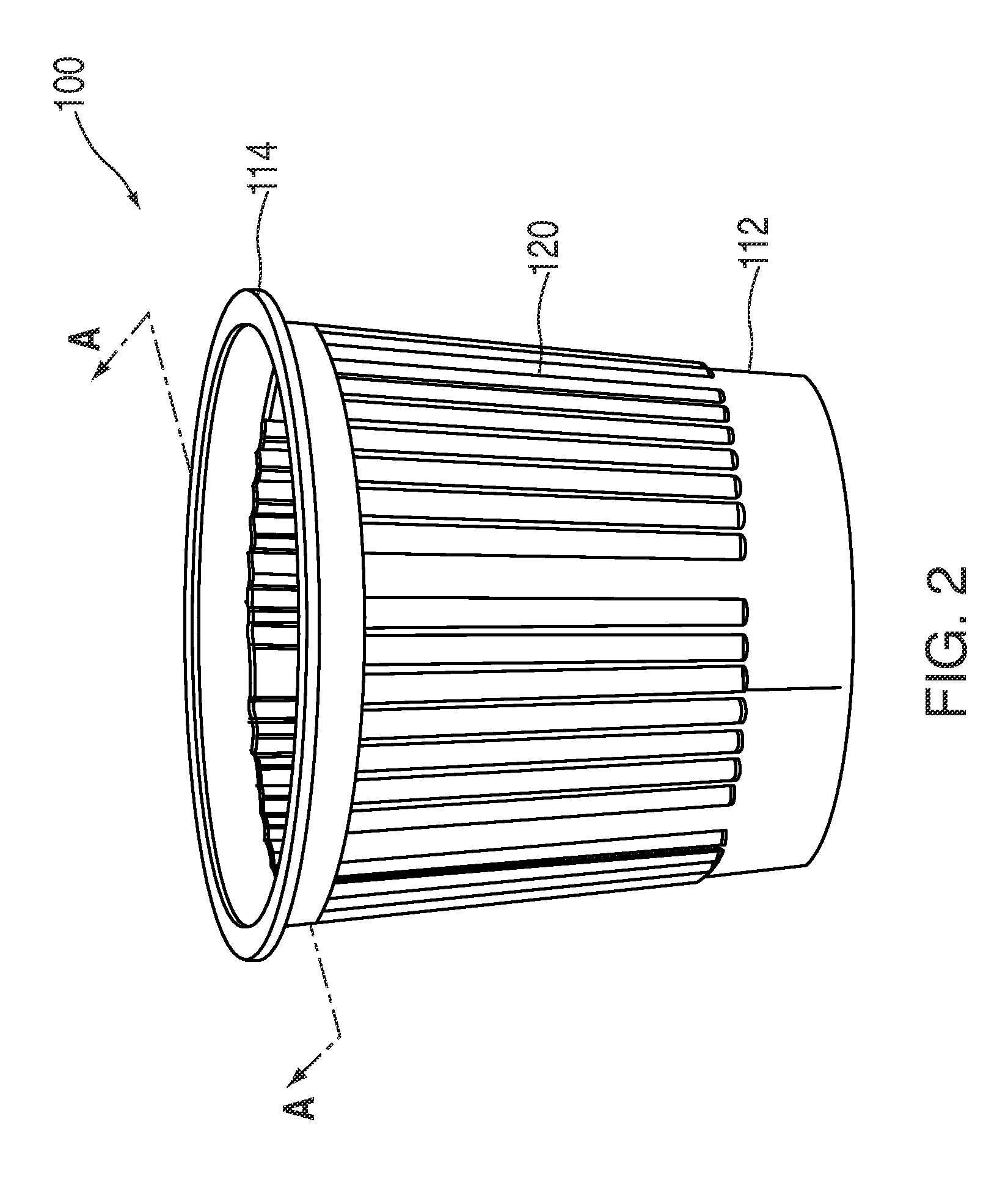

[0044]Reference is next made to FIG. 2, which is a perspective view of beverage cartridge 100 without top cover 116. As can be seen, body 112 has a series of channels 120 vertically oriented running from proximate the top surface of body 112 to proximate the bottom of body 112. The channels are made in the sides of beverage cartridge 100 in a fashion best seen in FIGS. 3, 4 and 5.

[0045]Wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com