Optionally Heated Moss Inhibitive Gutter Guard

a gutter guard and inhibitive technology, applied in the field of gutter guard systems, can solve the problems of blocking debris, non-provision for the inclusion or insertion of an intrinsic heating method or the area receiving a heating method, etc., and achieve the effect of reducing preventing or eliminating the growth of moss mold or mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

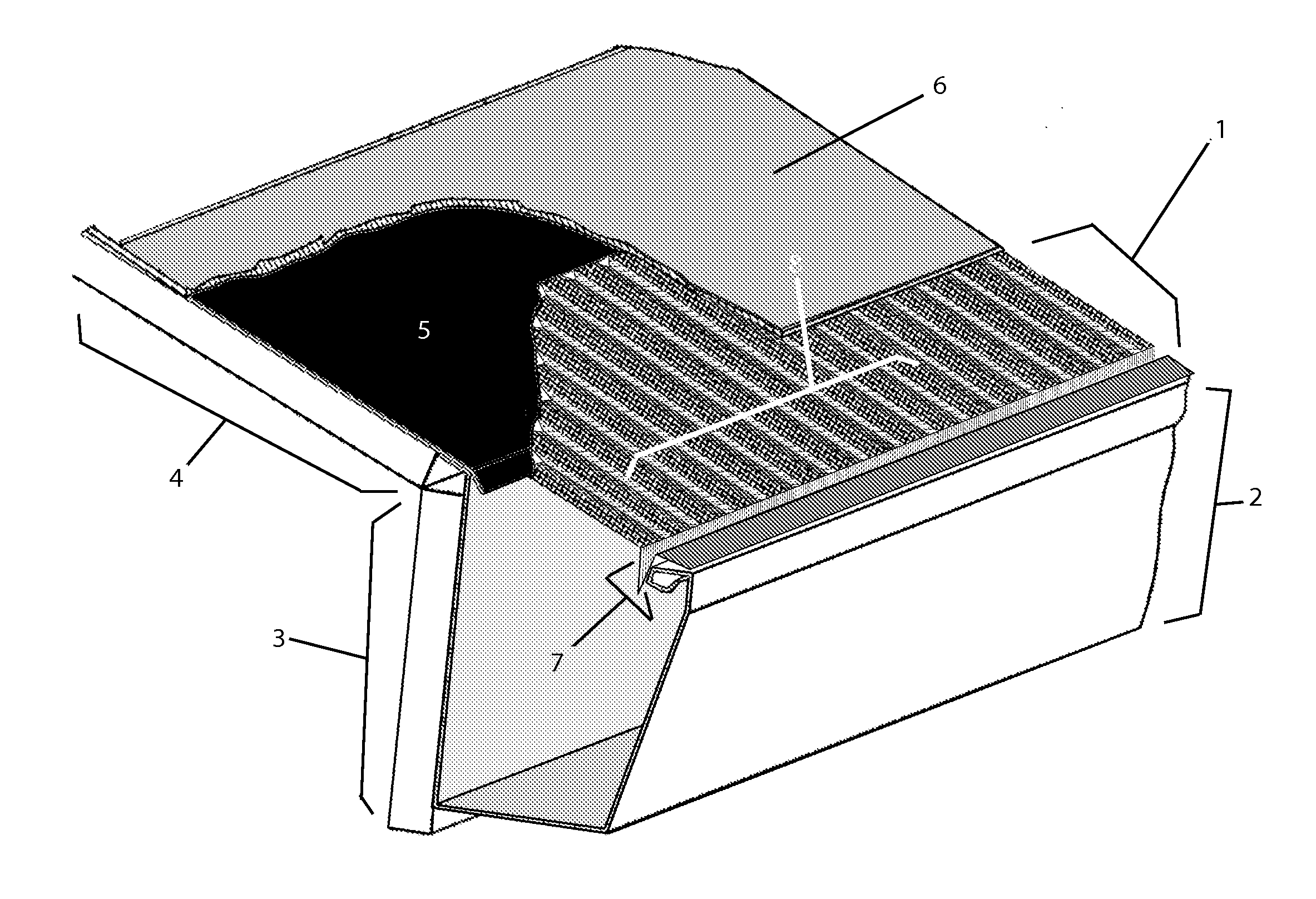

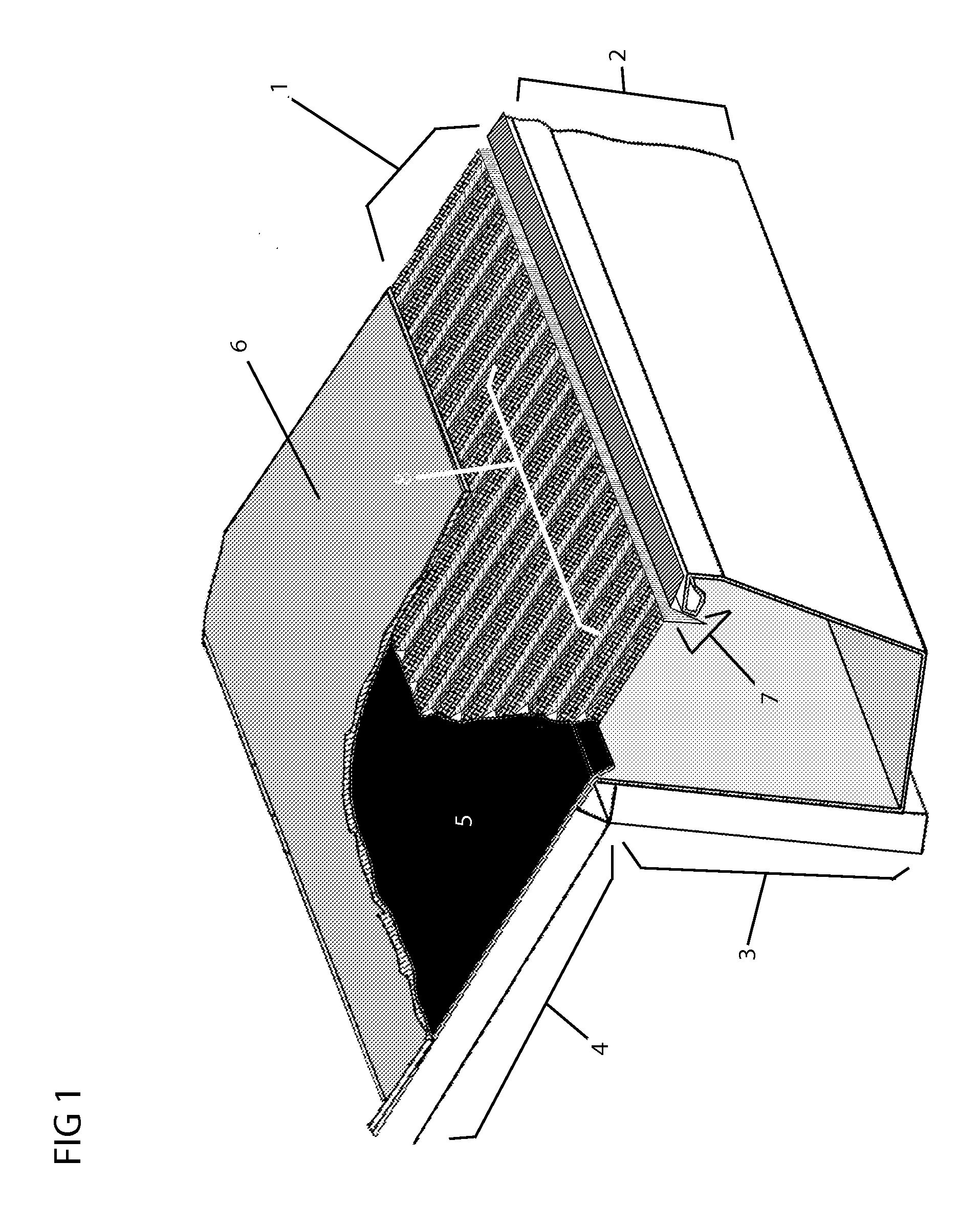

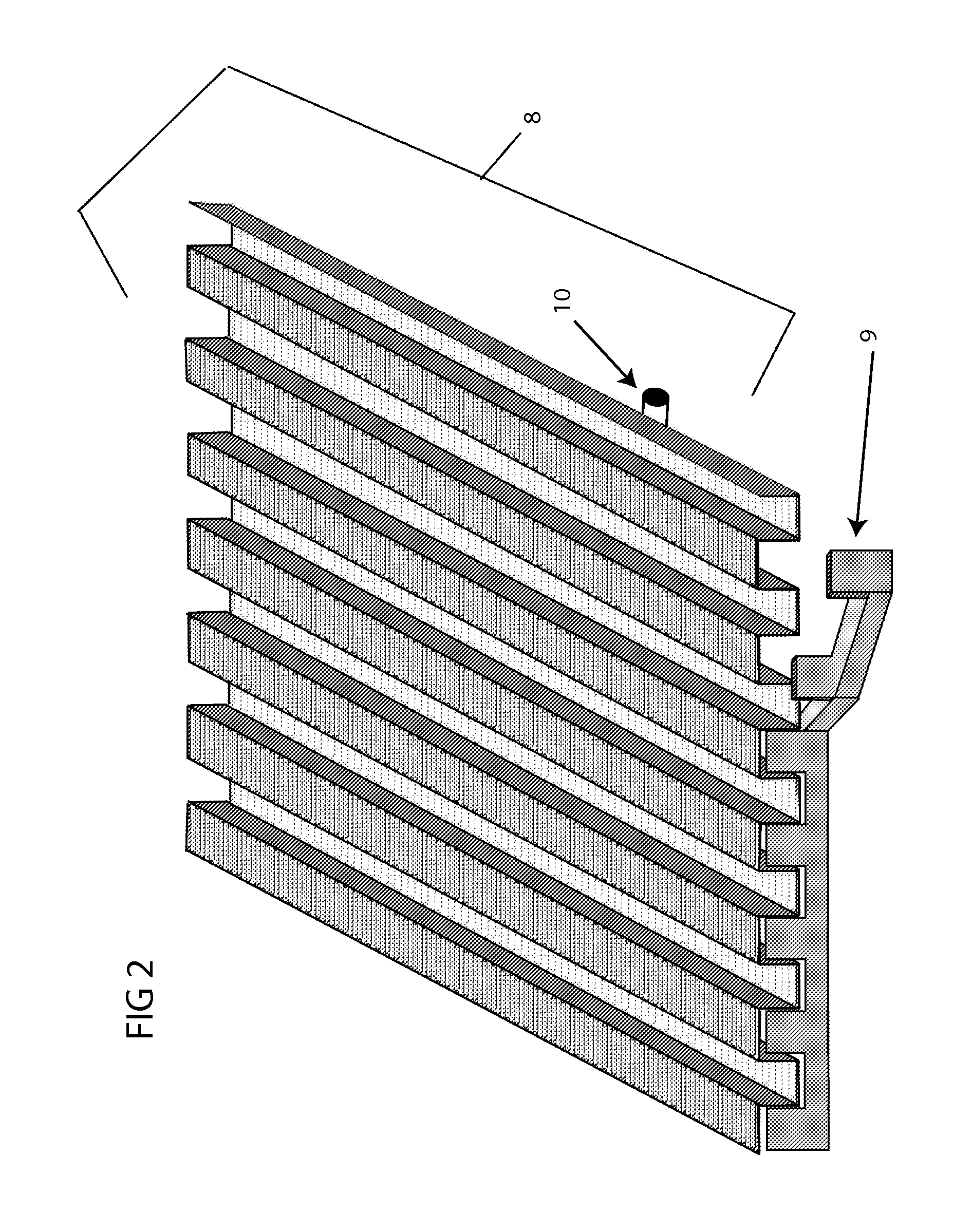

[0036]Referencing the drawings wherein like reference numerals represent like parts throughout the various figures, viewing (FIGS. 1 and 2) reference numeral 1 is directed to a gutter guard system mountable overlying an opening on an upper portion of a gutter 2. The gutter 2 is attached to a fascia 3 along a lower edge of a roof 4 to capture water running off of shingles or other roof cover 6 supported over a moisture barrier 5. Water runs off the shingles 6 and then down onto the gutter guard system 1 overlying the gutter 2. Viewing (FIG. 2)8, the system is primarily formed of screen or other porous material shaped into a corrugated form, the porosity enabling water to pass through and downward to the underside of the rear wall 18 of downward extending L-shaped plane 15 extends to a height greater than the top surface of areas 8C and 8B. water flowing along the top and bottom surface of area 8B of the corrugated screen 8 will be impeded in its forward flow upon encountering rear wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com