Firearm with dual charging handles

a charging handle and firearm technology, applied in the field of firearms, can solve the problems of difficulty in operation of the top-mounted charging handle, the time between failures, and the size of the charging handle for use by someone wearing gloves and protective clothing, so as to improve the appreciation of the contribution to the art

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

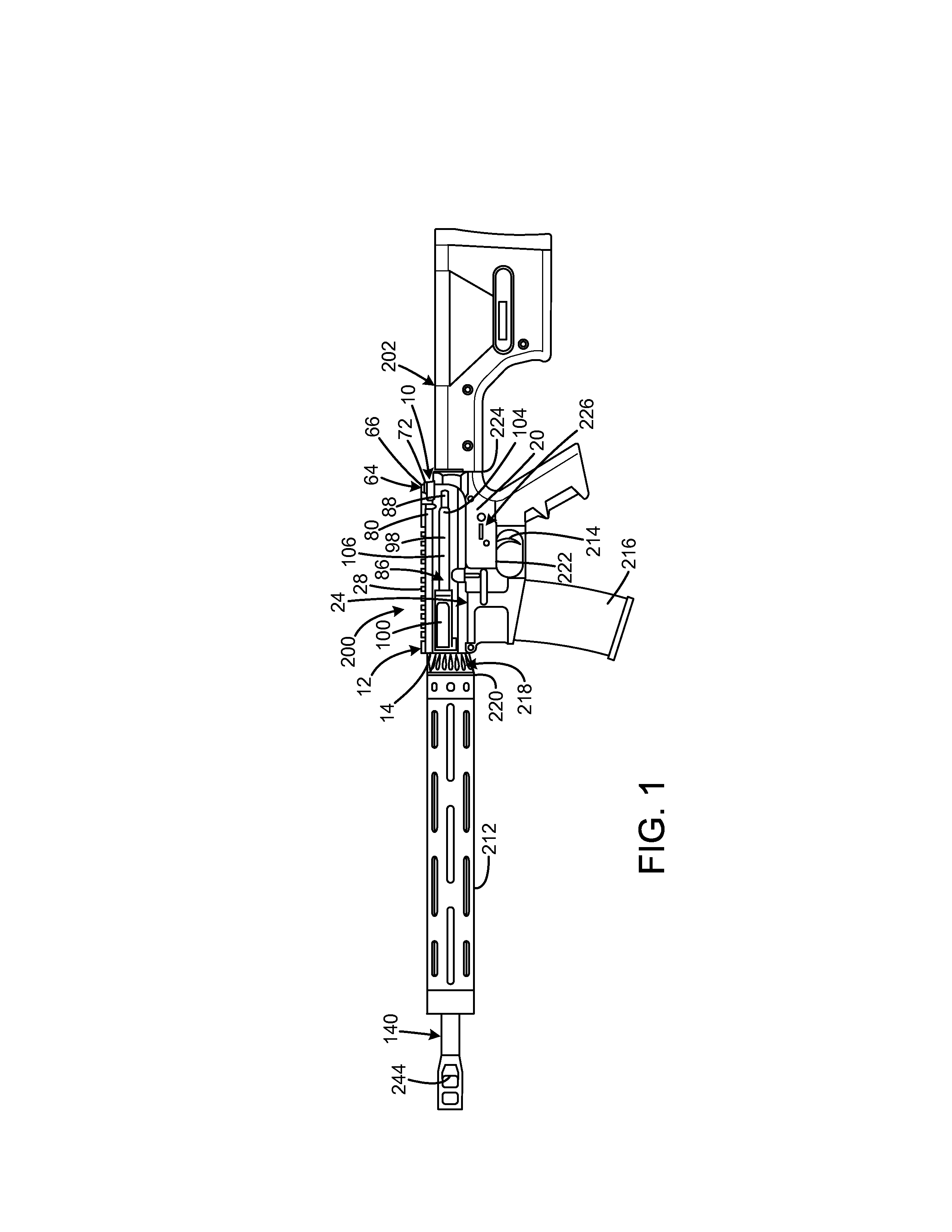

[0032]An embodiment of the firearm with dual charging handles of the present invention is shown and generally designated by the reference numeral 200.

[0033]FIG. 1 illustrates the improved firearm with dual charging handles 200 of the present invention. More particularly, the firearm is a rifle having an upper receiver assembly 10 with a stock 202 extending rearward from the rear 224 of the lower receiver 226. A trigger 214 and a magazine 216 extend downwardly from the lower receiver's bottom 222.

[0034]The muzzle 244 end of a barrel 140 extends forwardly from the front 14 of the upper receiver 12. The barrel has a central bore 142. A hand guard 212 removably encircles the barrel with the hand guard's rear 220 abutting the front of the barrel nut 218, and the barrel nut abuts the front 14 of the upper receiver.

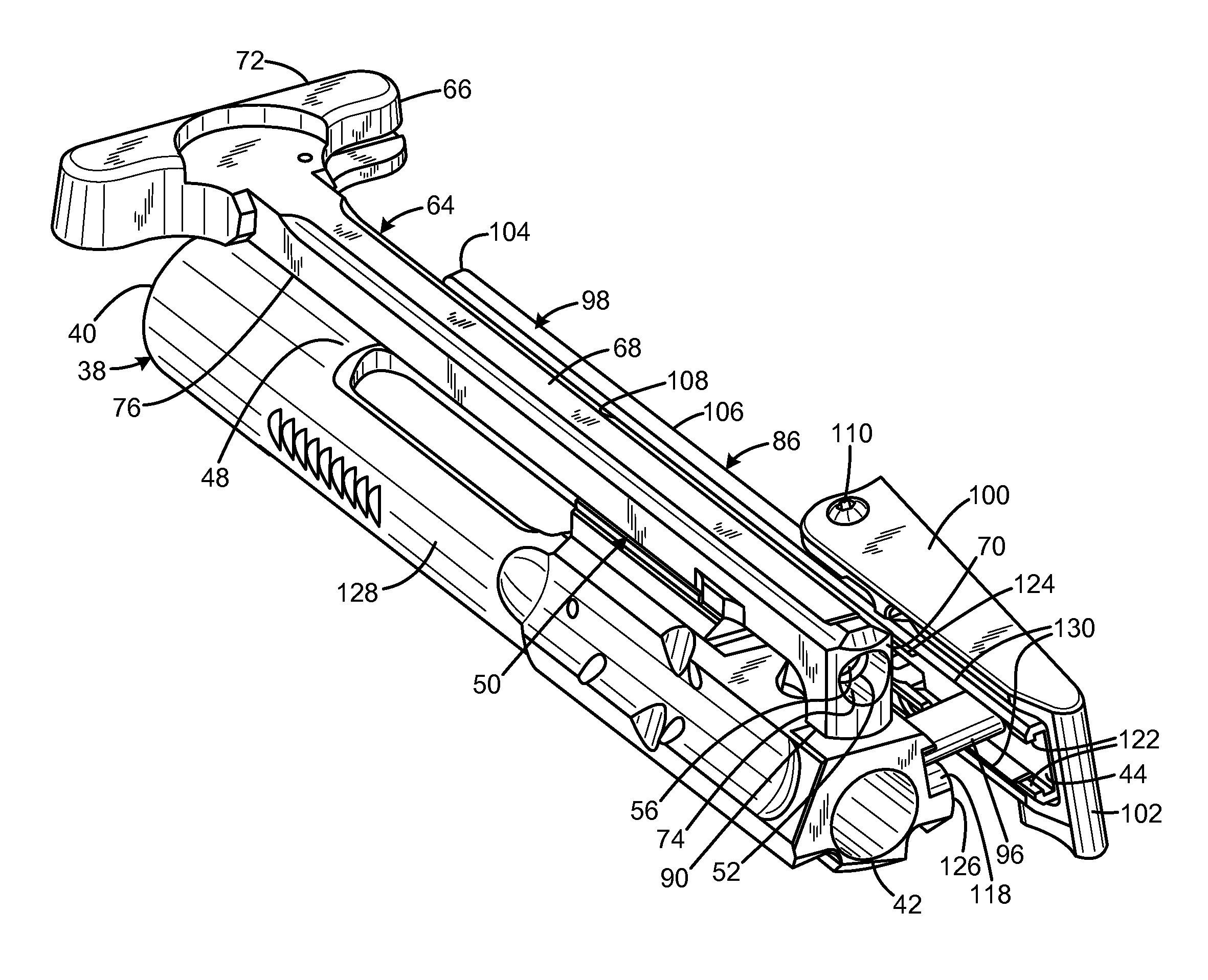

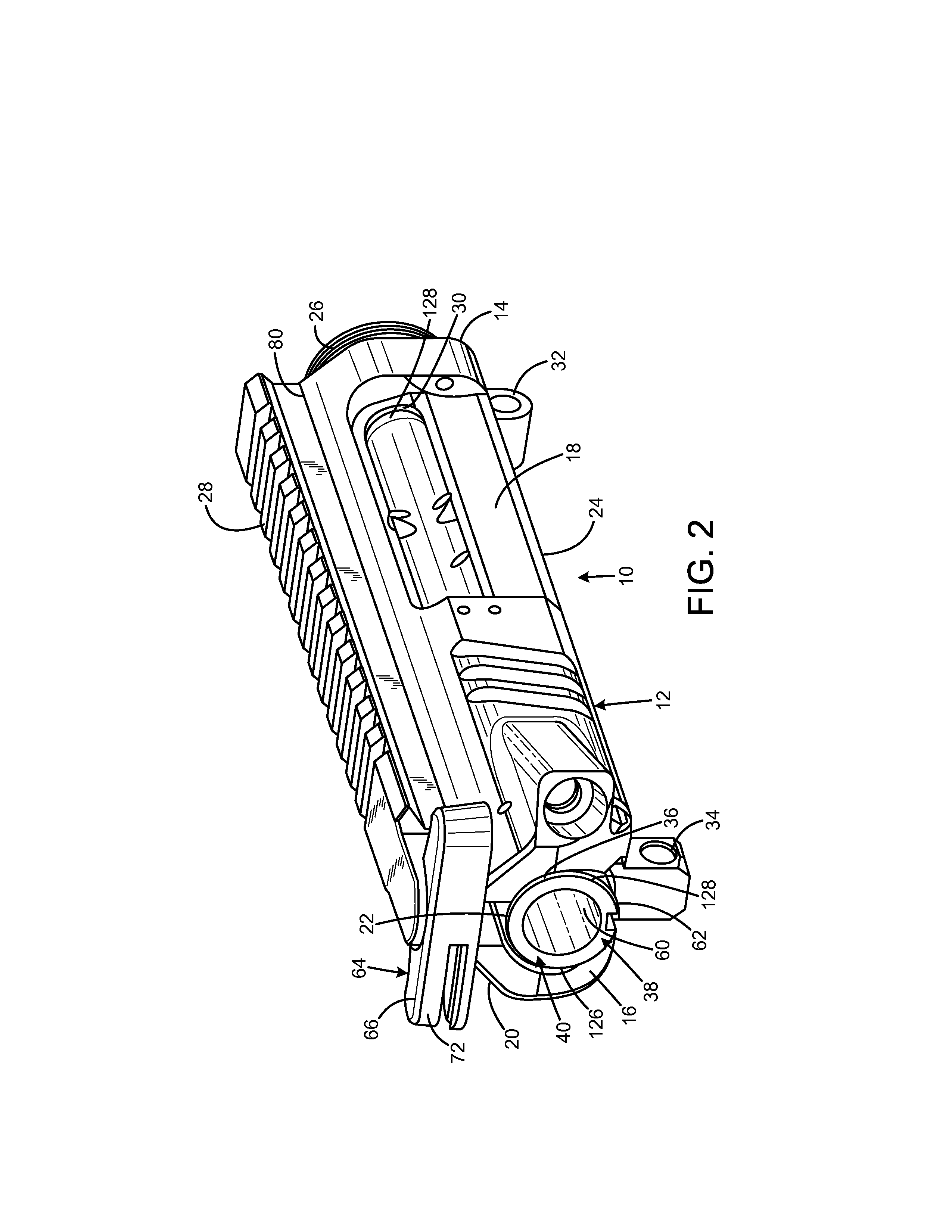

[0035]FIGS. 2-4C illustrate the improved upper receiver assembly 10 of the present invention. More particularly, the upper receiver assembly has been removed from the firearm 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com