Carburizing steel having excellent cold forgeability and method of manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

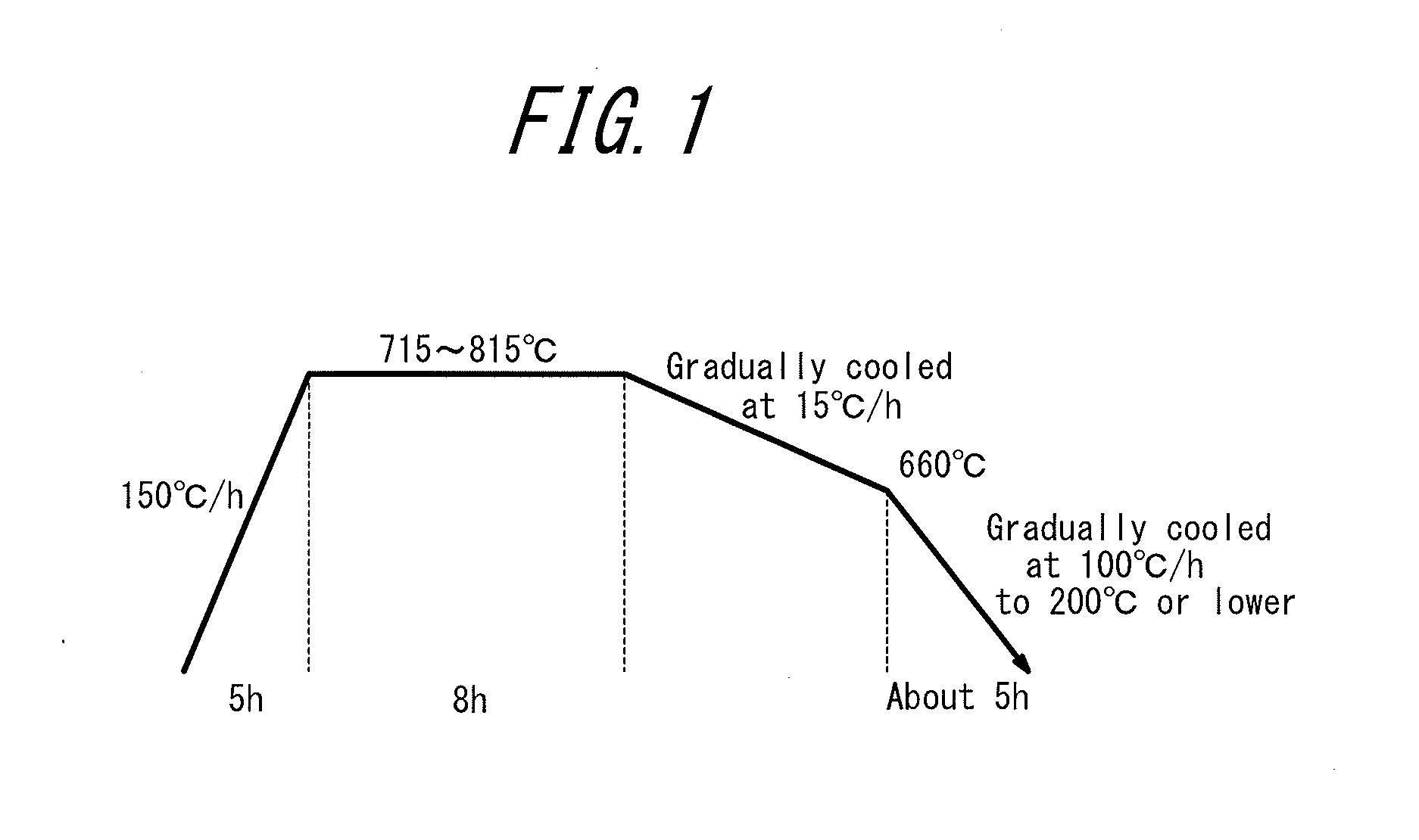

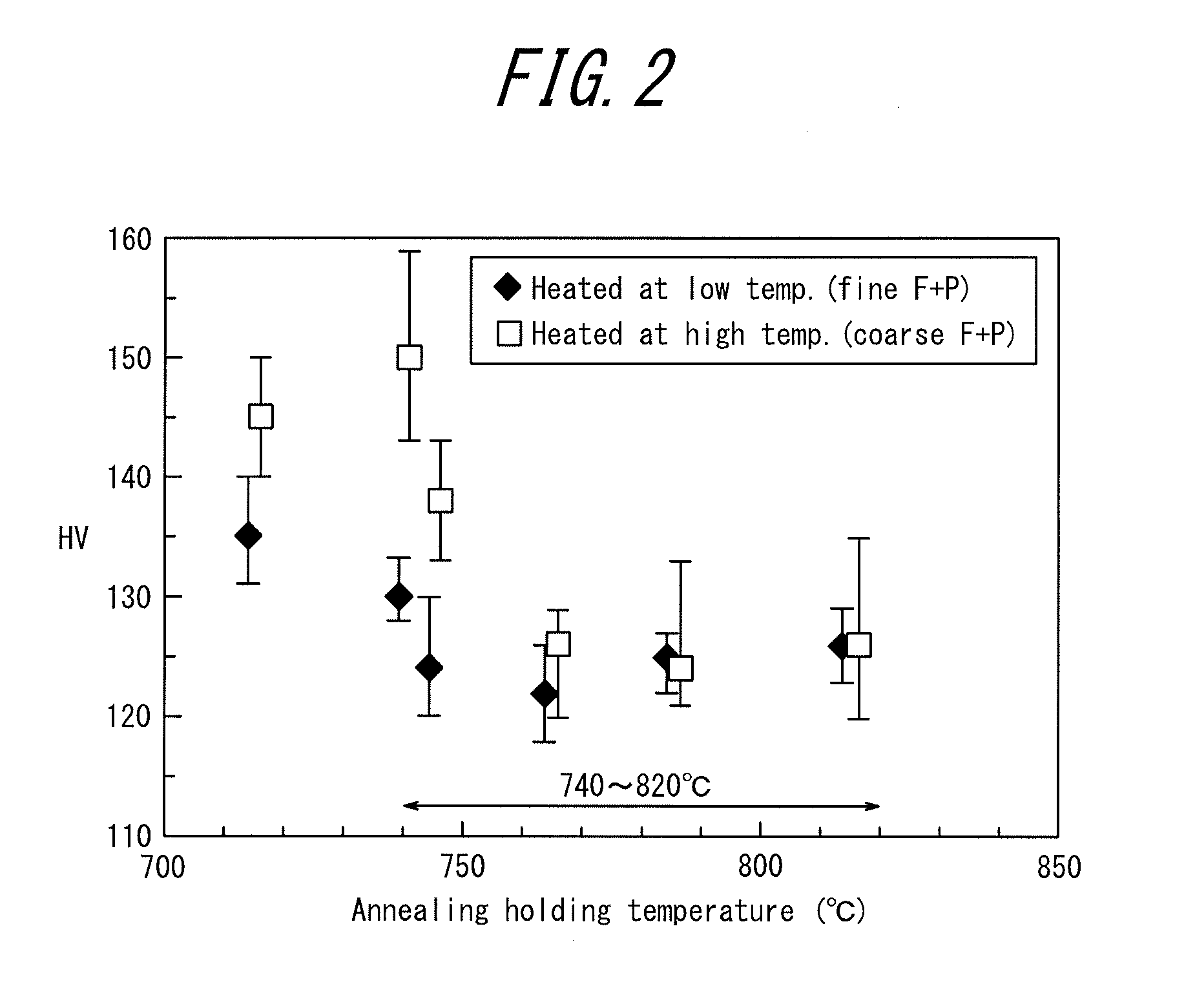

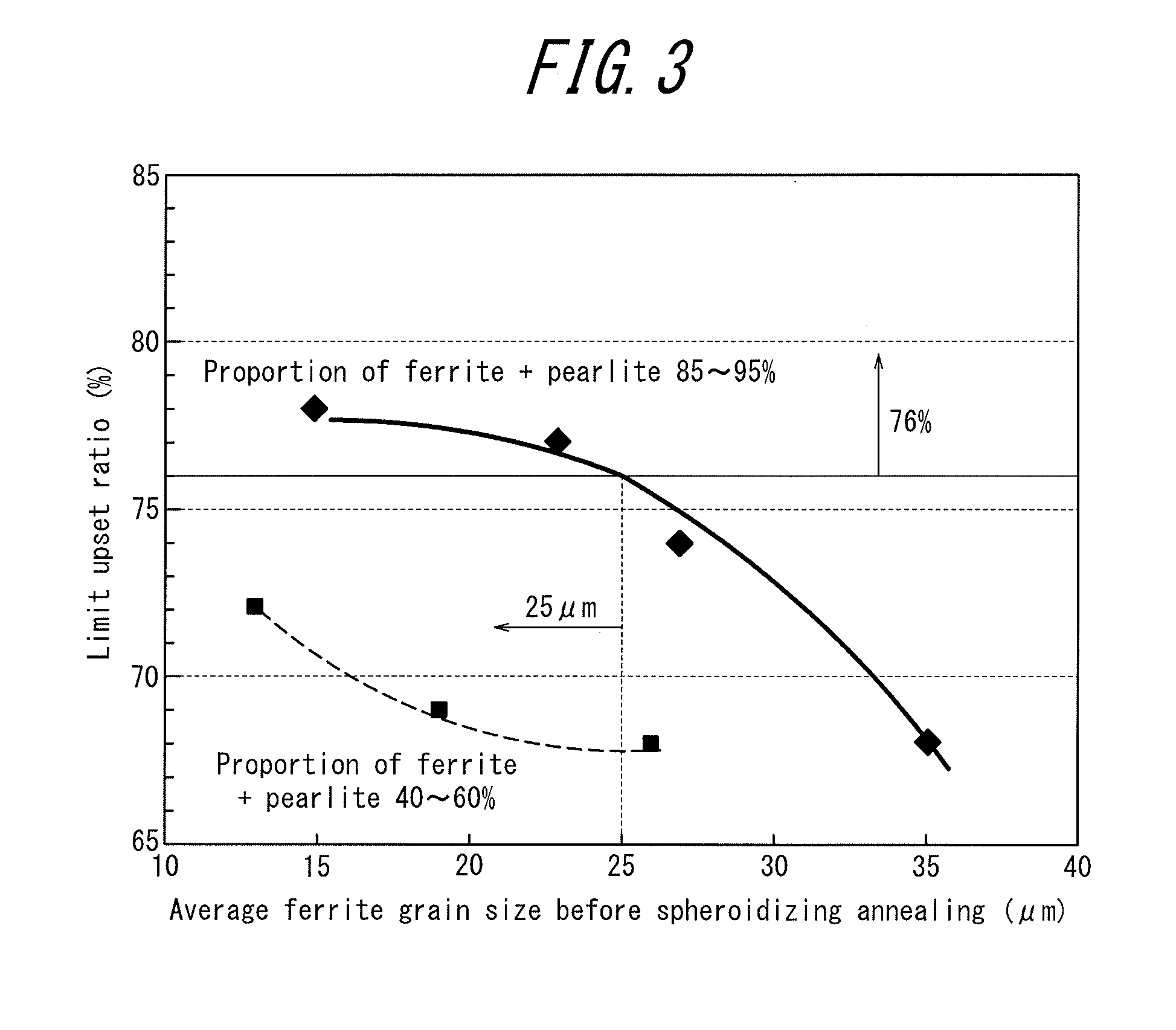

[0133]Steel samples having different chemical compositions shown in Table 1 were prepared by steelmaking in a 100 kg vacuum melting furnace to produce cast steel products, which in turn were subjected to rolling under the hot working and cooling conditions as shown in Table 2 to be finished to steel bars. That is, the steel samples were subjected to the first stage hot working where they were heated at respective heating temperatures as shown in Table 2, then cooled to 450° C. or lower, and thereafter subjected to the second stage hot working where they were heated, rolled and cooled under the conditions as shown in Table 2 relating to the heating temperature, total reduction rate and cooling rate, to thereby obtain steel bars. The resulting steel bars were evaluated for their microstructure proportion and average ferrite grain size, cold workability, spheroidizing heat treatability, properties of carburized portions, and fatigue properties. The evaluation was made under the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com