Inclined manhole cover riser assembly

a manhole cover and assembly technology, applied in the direction of artificial islands, foundation engineering, construction, etc., can solve the problems of depression in the roadway, difficulty and cost of raising the existing manhole frame sufficiently, and the resurfacing of the roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

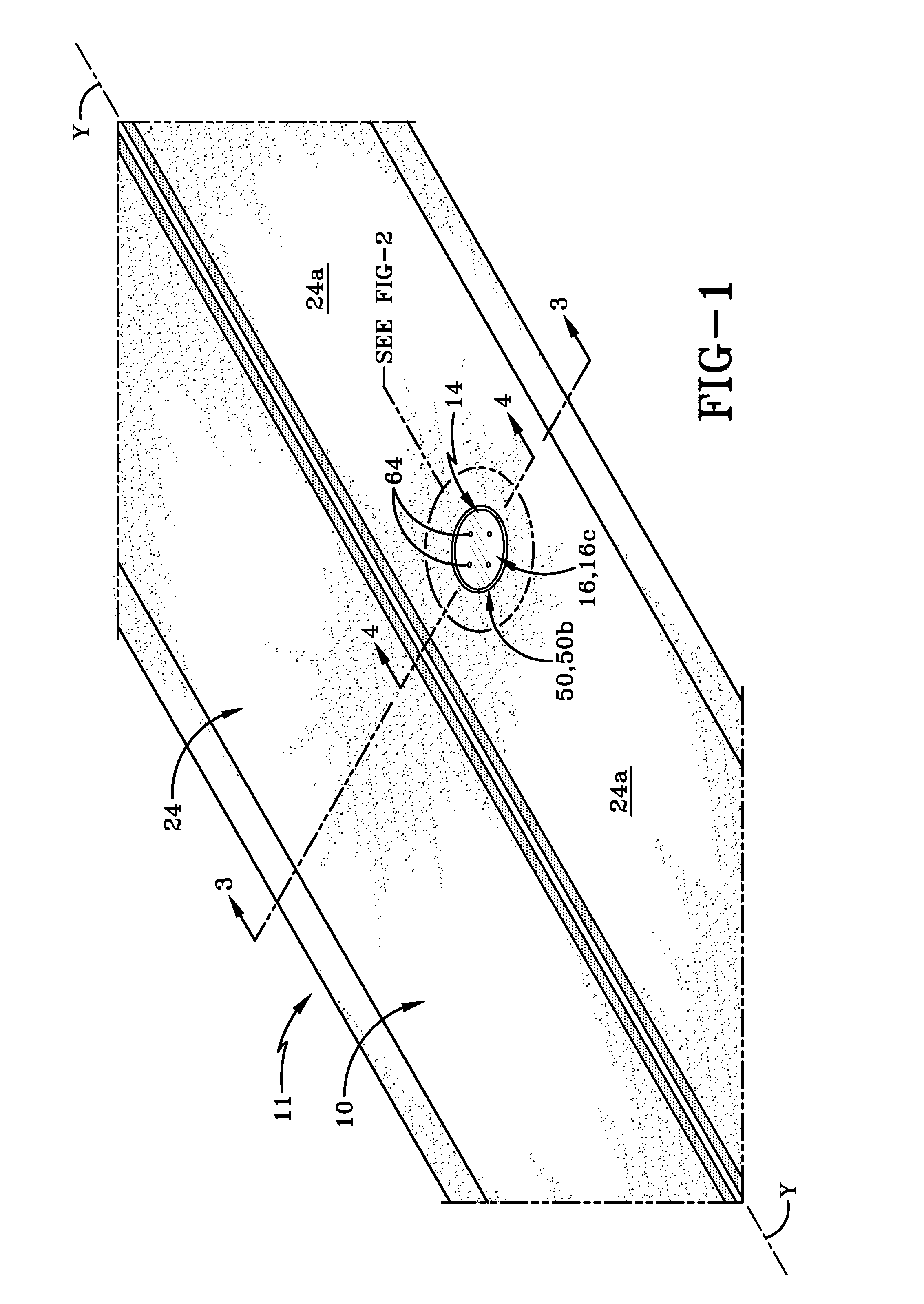

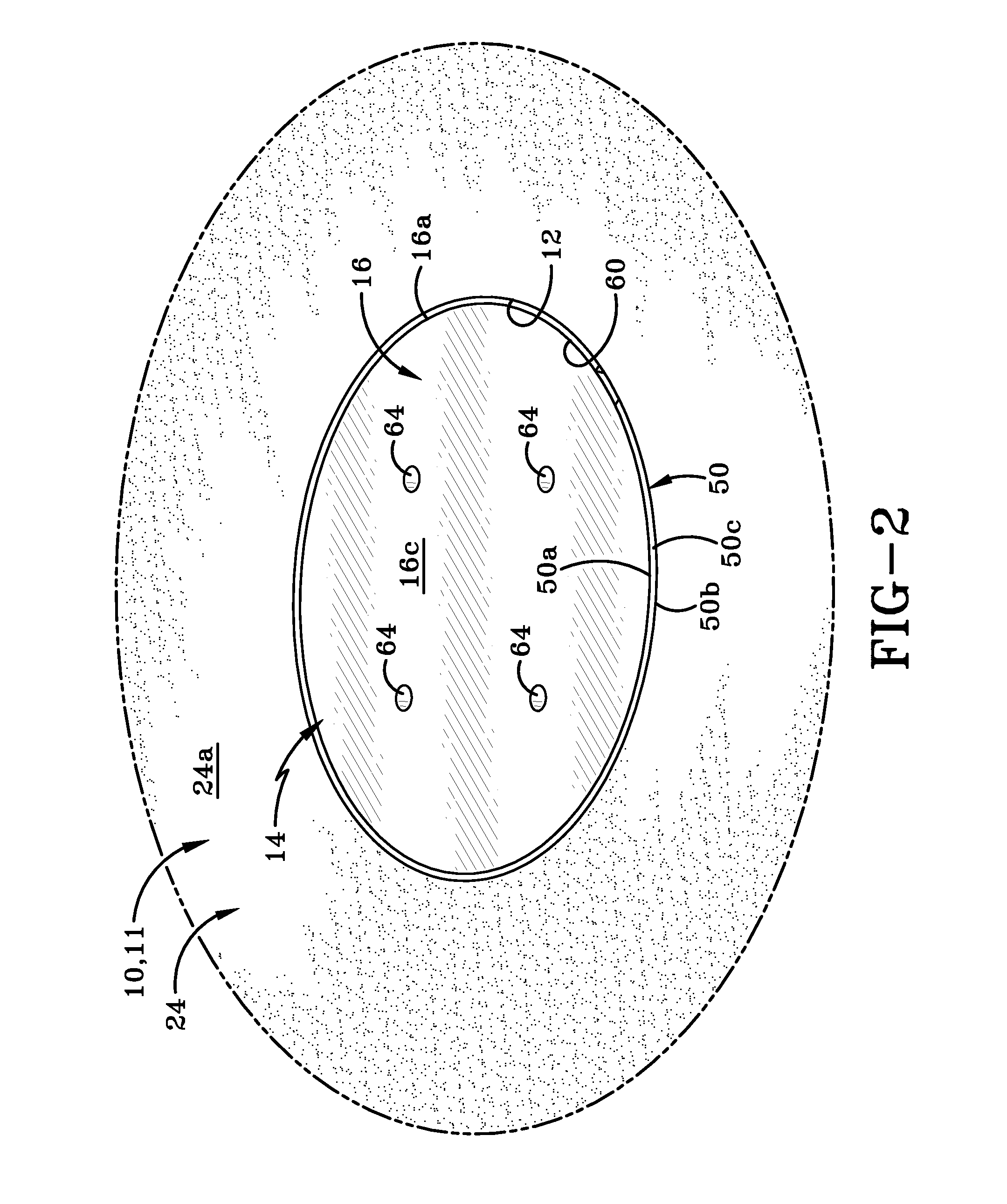

[0035]Referring to FIGS. 1 and 2, there is shown a paved surface or pavement 10 in which is defined an access hole 12 to a manhole assembly 14. A manhole cover 16 is engaged with manhole assembly 14 to close off access hole 12. Pavement 10 may be any type of surface including a road, a parking lot, a sidewalk etc. that includes a manhole assembly 14 and the paving material applied to pavement 10 may be asphalt, concrete or any other type of material that is applied in layers to form a rigid surface over which people and / or vehicles travel. In particular, the area of pavement 10 surrounding manhole assembly 14 is sloped in any one of a number of directions.

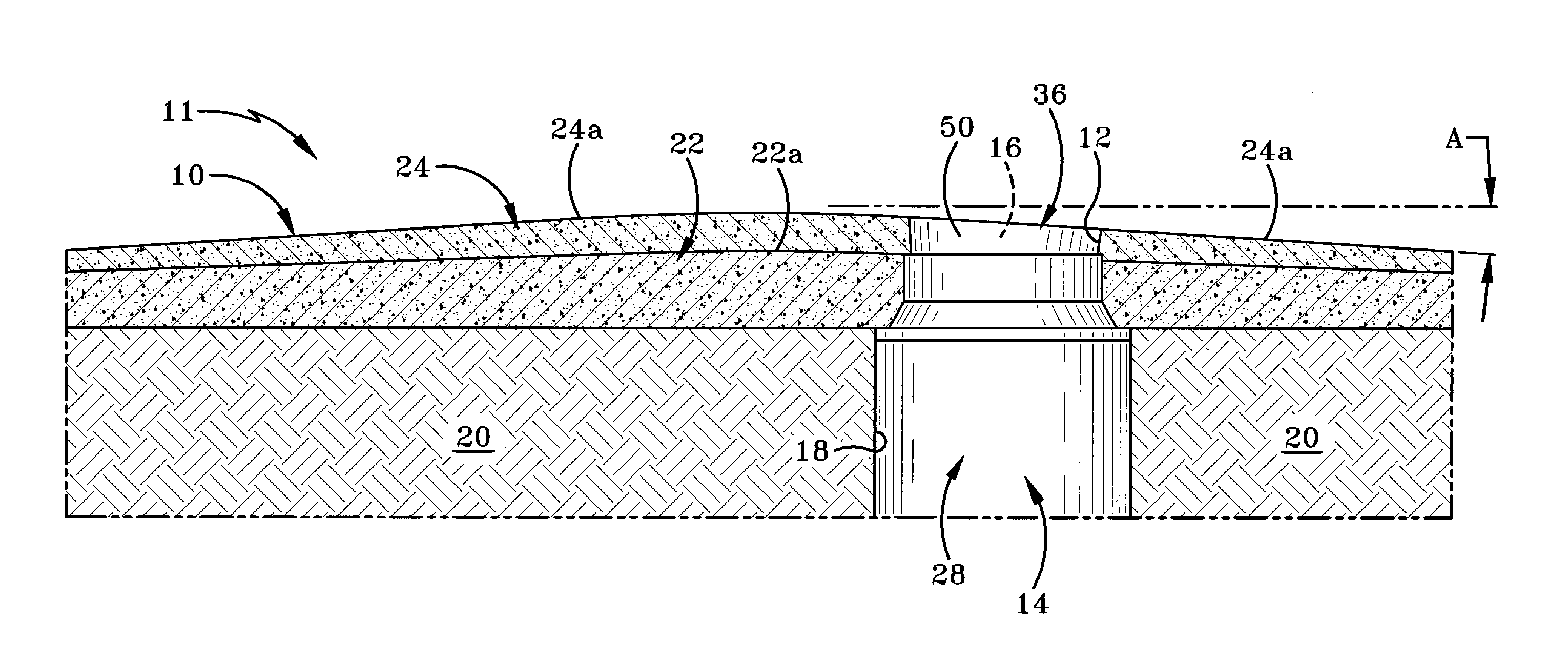

[0036]FIGS. 3 and 4 are cross-sections through pavement 10. FIG. 3 shows that manhole assembly 14 includes a manhole frame 28 disposed in a cavity 18 formed in a brick or masonry storm drain system 20 which is disposed beneath pavement 10. Pavement 10 comprises an original layer 22 of paving material and a new layer 24 of paving ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com