Self sealing waterproof bag

a self-sealing, waterproof bag technology, applied in the direction of handbags, flexible container closures, transportation and packaging, etc., can solve the problems of human intervention, water resistance qualities, and not self-sealing, and achieve automatic, rapid and efficient sealing of containers, and protect valuables free of water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

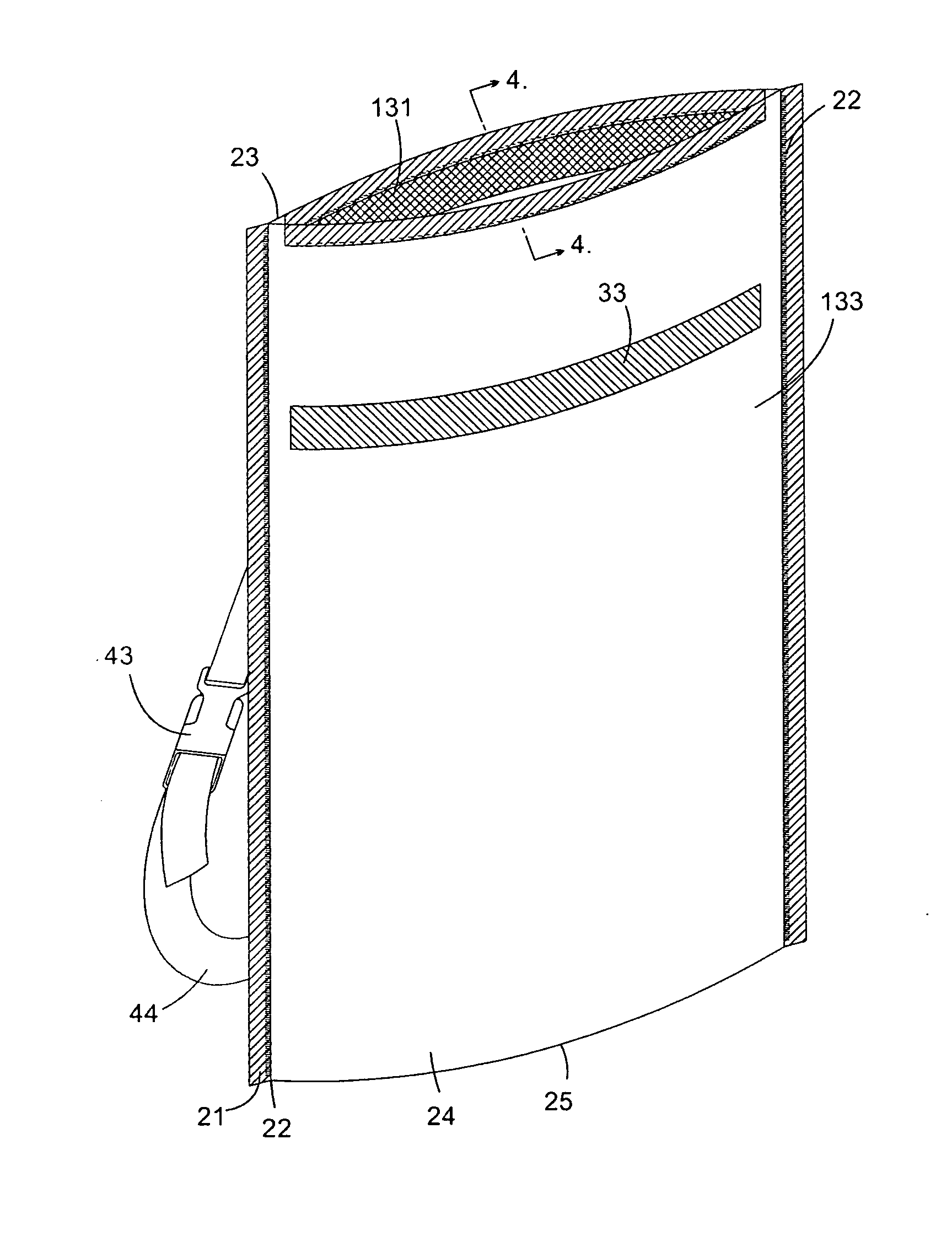

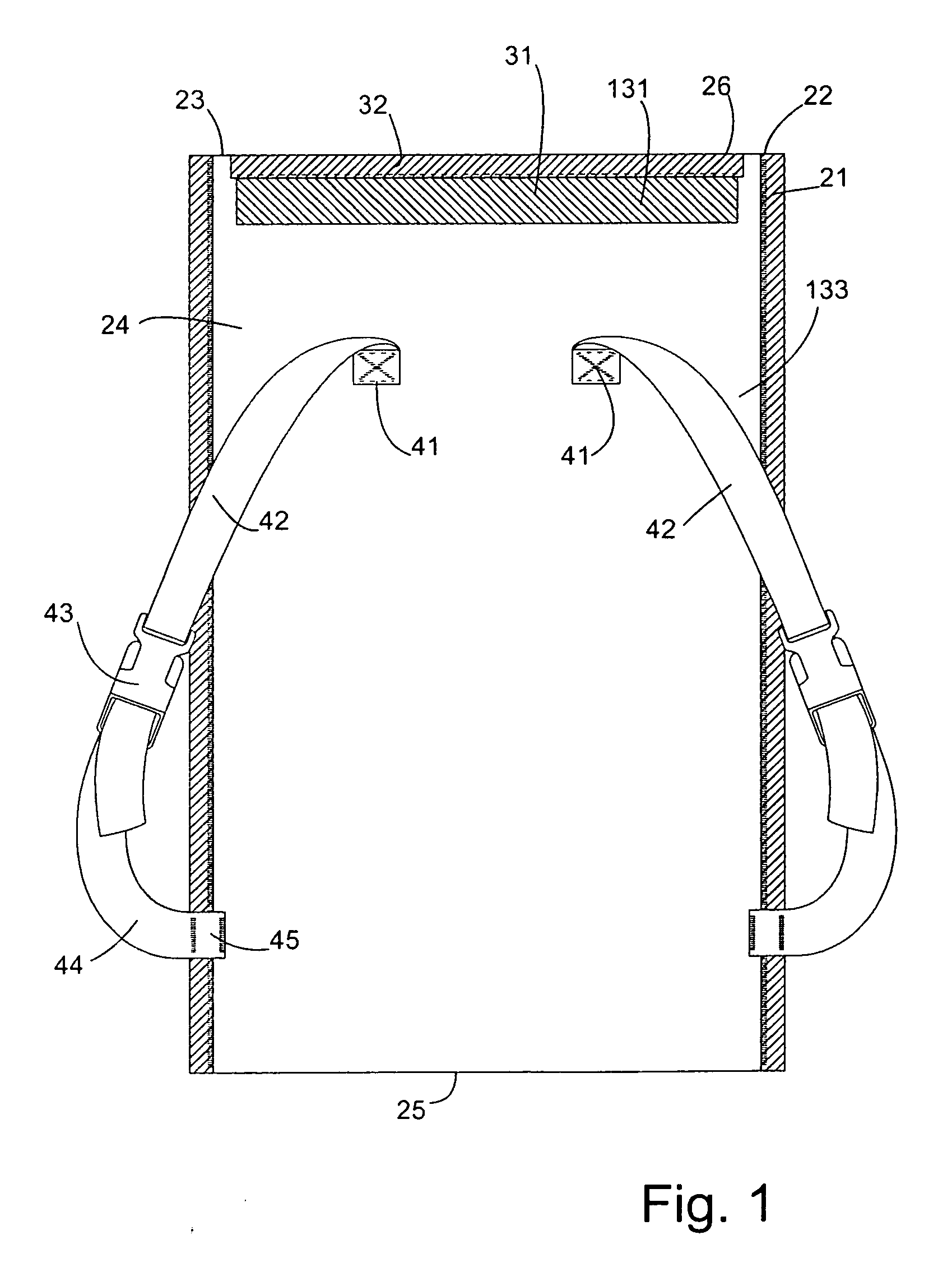

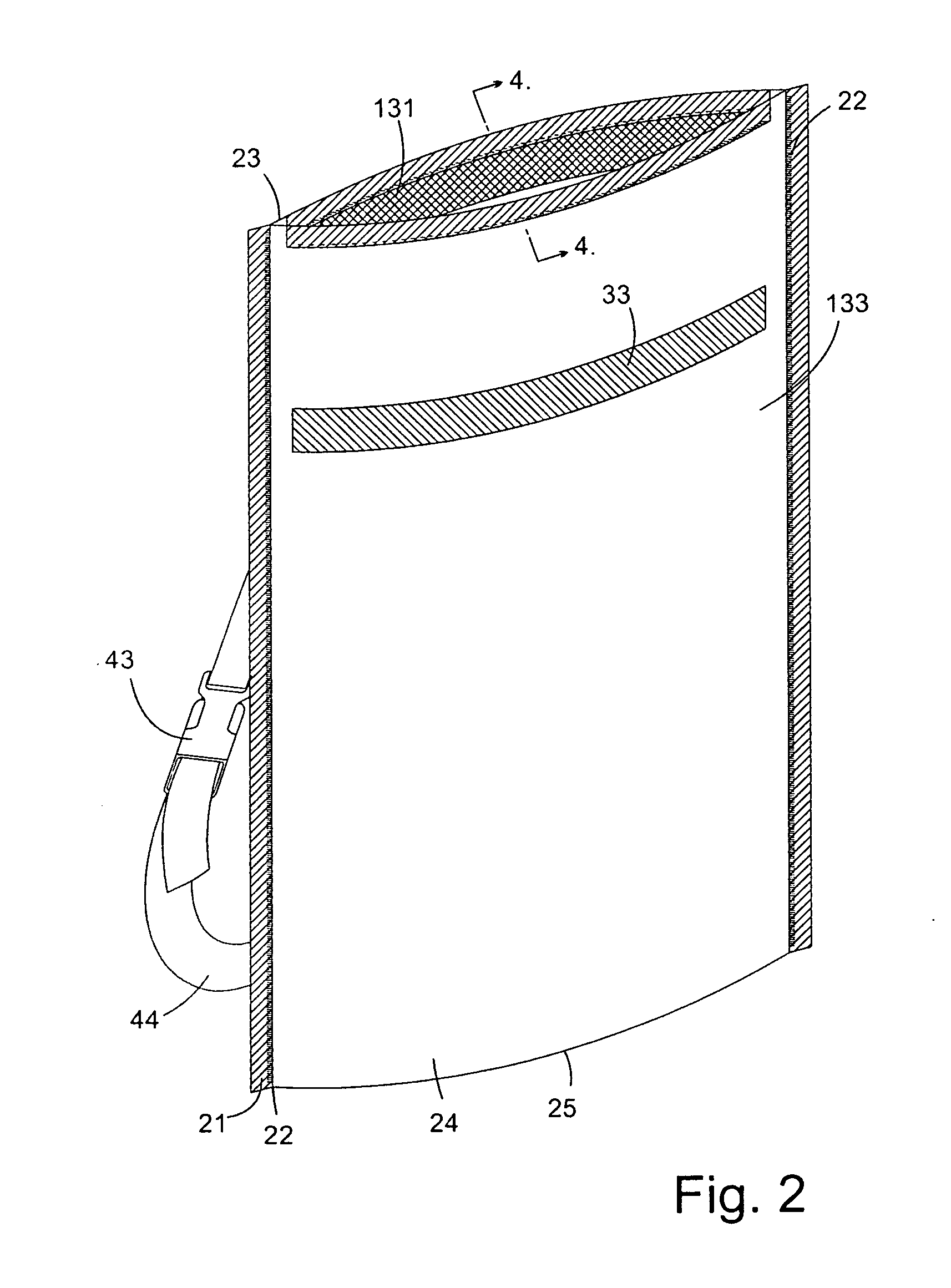

[0061]The self sealing container has one or more openings using magnet to magnet contact, preferably making the container water-resistant and airtight. The specialized magnet to magnet seal may be used in, for example, but not limited to, bags, backpacks, pockets, duffle bags, soft coolers and handbags. More specifically, this invention relates to sealing containers without human intervention and using only flexible magnet-to-magnet contact. When left hands-free, the magnet to magnet contact and bias rods pops the opening closed.

[0062]The present invention is constructed on a sheet of waterproof fabric using a length of fabric and folded so as to have a fold line 88 to form a fold edge 25 at a bottom of the bag. The sides of the bag are stitched with thread and a strip of seal 22 material is laminated over the stitching holes on the inside of the bag. The seal strip 22 is heat laminated and pressed against the stitching holes on the inside of the bag. The seal strip 22 is reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com