Fluid motor under variable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

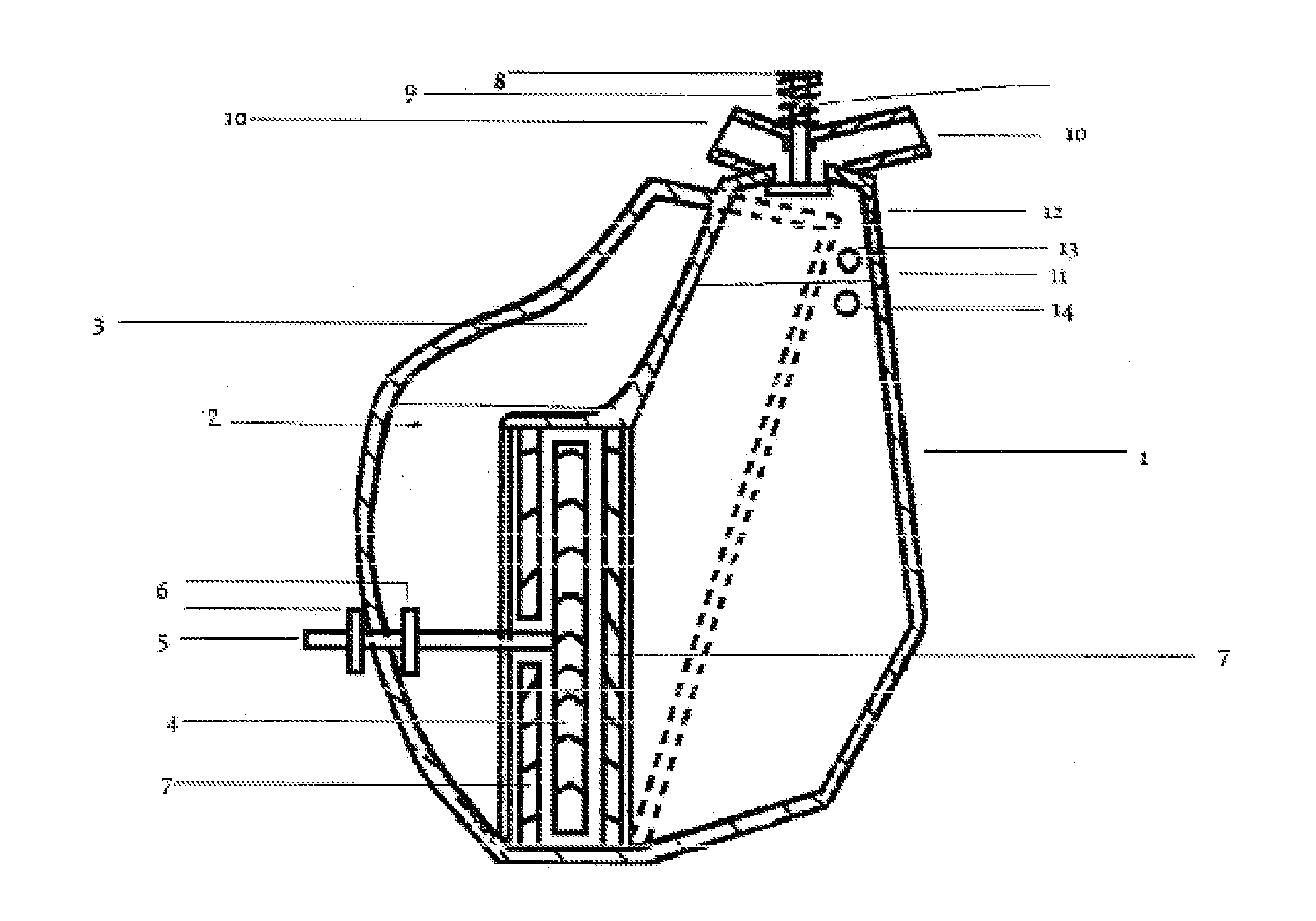

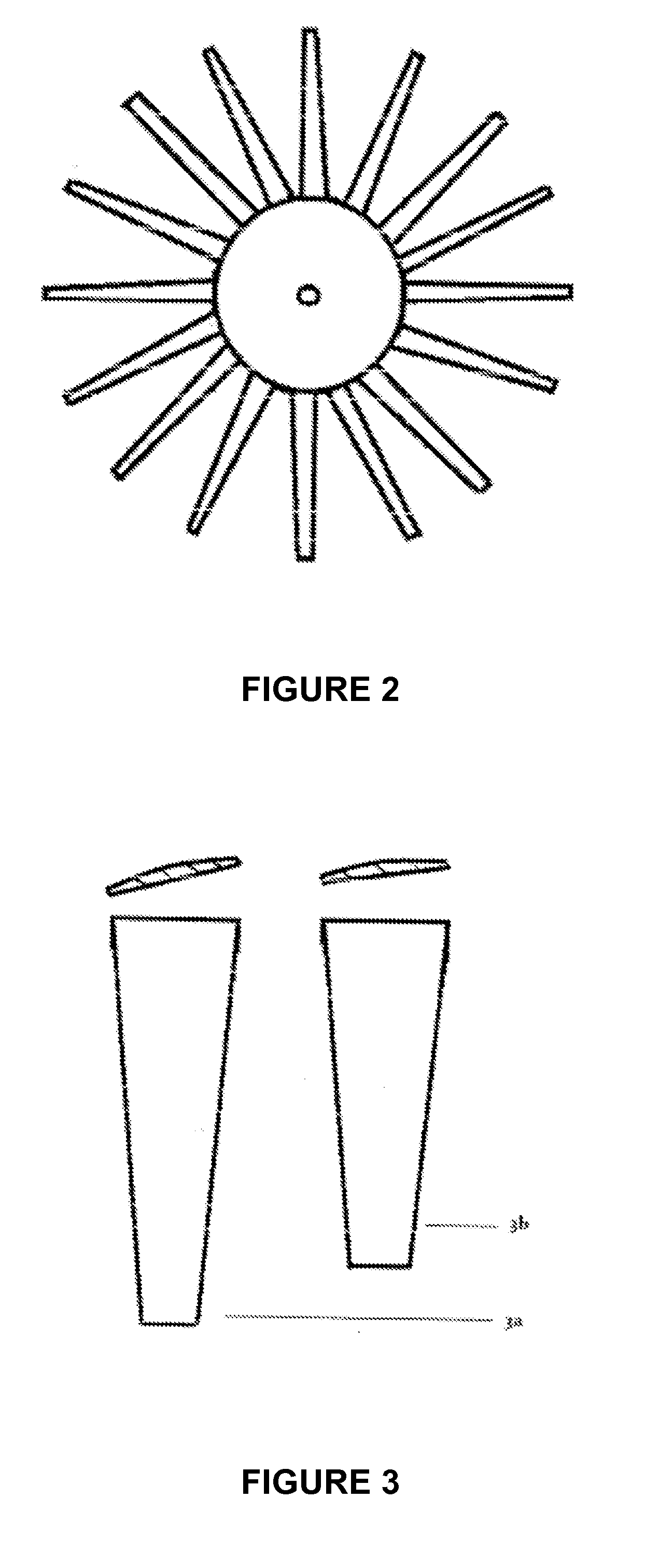

[0011]As can be observed from the drawings, the present invention is comprised of a conical cylinder 1, therein containing liquid 2 and gas flow. The conical cylinder is encompassed almost totally by a cavity 3 that contains also part of the pressurized liquid flow and gas flow.

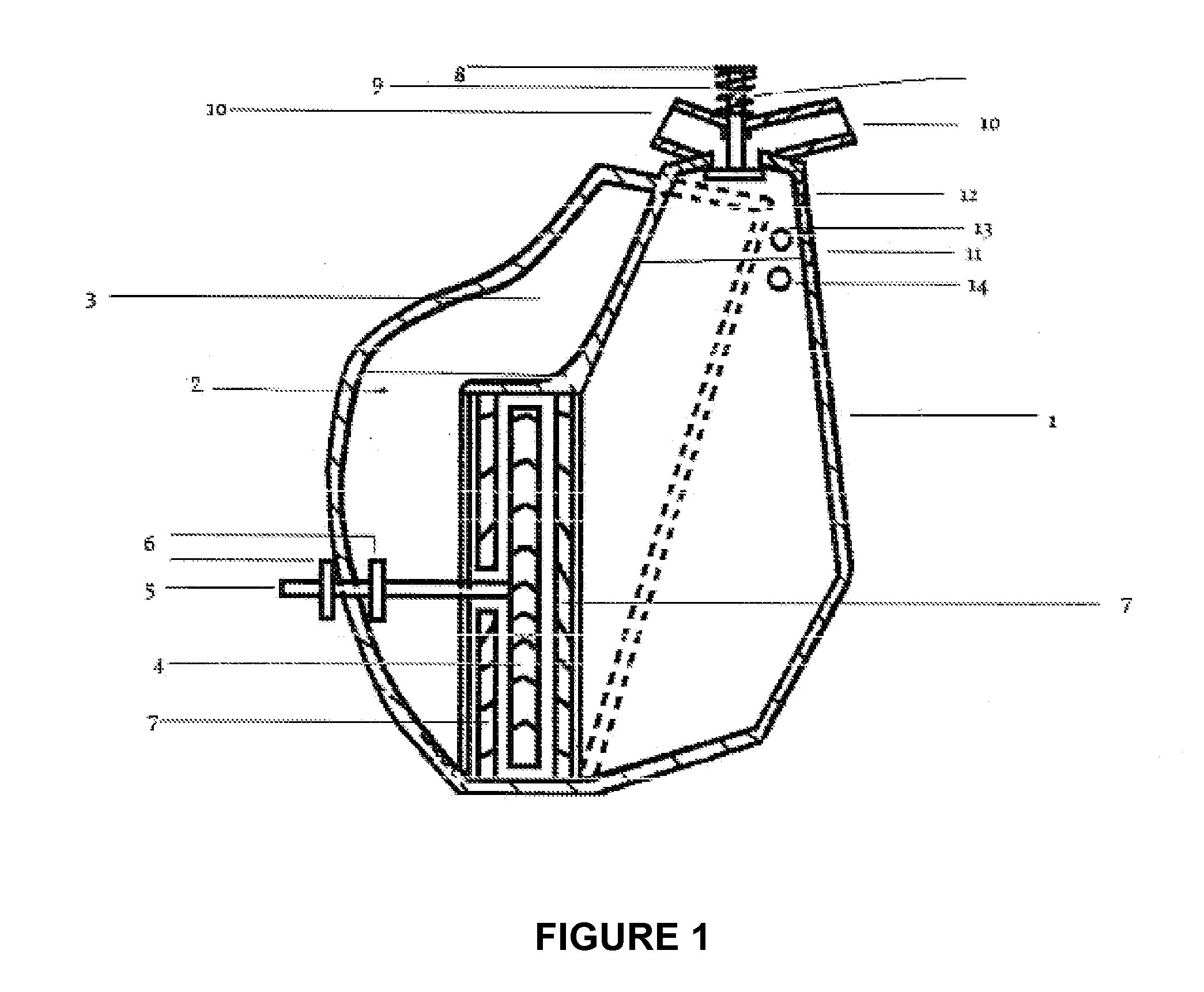

[0012]The conical cylinder 1 contains, also in its interior, a turbine 4 that contains in its shaft 5 two buffer stops that keep it in place; blades 7 deflect the liquid flow towards the turbine. At the upper part of the conical cylinder 1 there is a valve 8 supported by a spring 9, next to it there are gas input and output cavities 10 for placing the injector 11, the spark plug 12 and the ignition sensor 13 and injection 14.

OPERATION

[0013]There follows the description in numbered steps of the operation of such invention:

[0014]1. The injector injects combustible to the air compressed by the liquid flow activated by the compression cavity, then the mixture is initiated through the order of the two injection se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com