Applicator device for applying a cosmetic, applicator element therefor, and cosmetic unit comprising the applicator device

a technology of applicator device and cosmetic, which is applied in the direction of applications, packaging goods, brushes, etc., can solve the problem that the arrangement of the application organ/bristle attached with the flocking method cannot always be predicted accurately, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

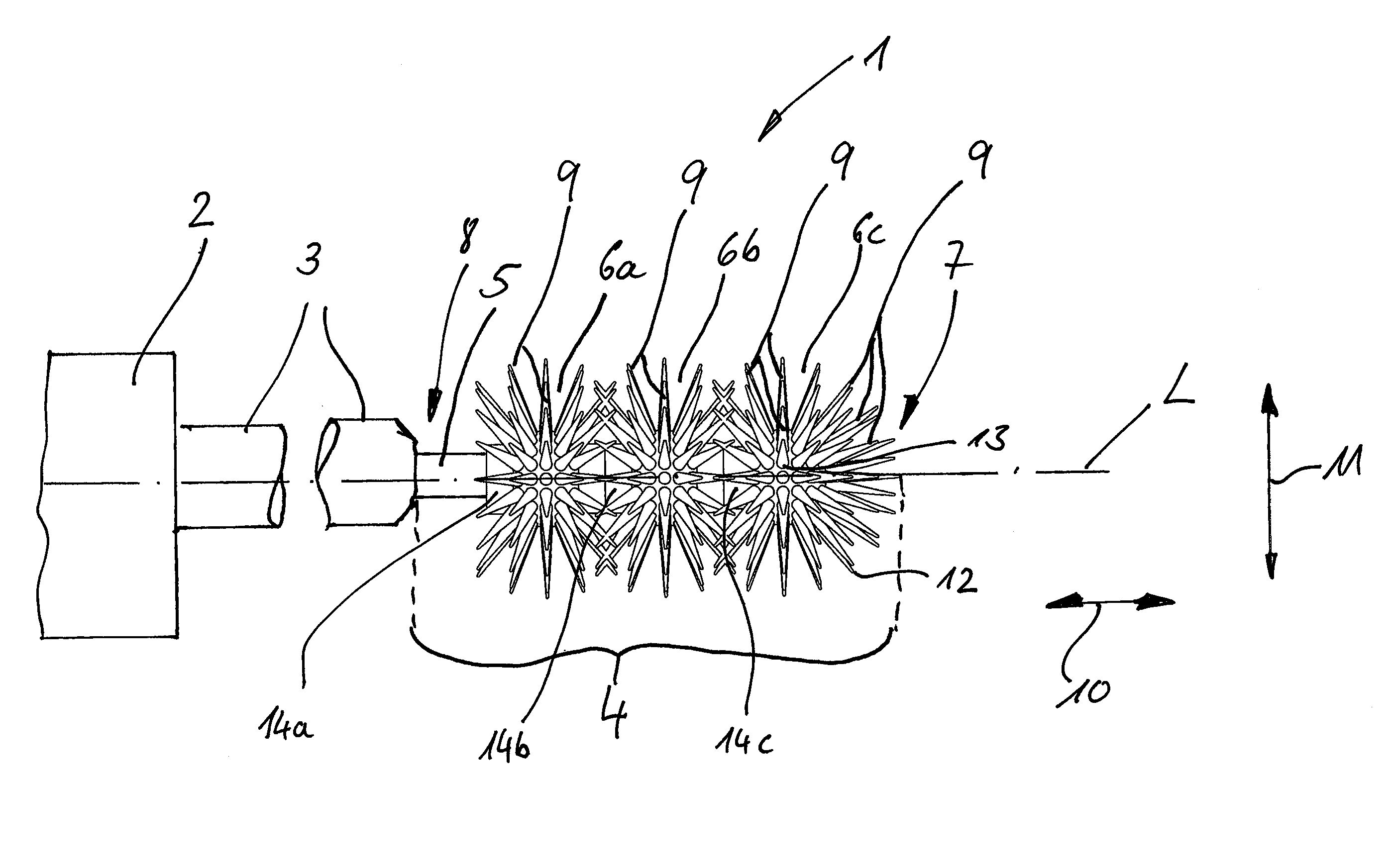

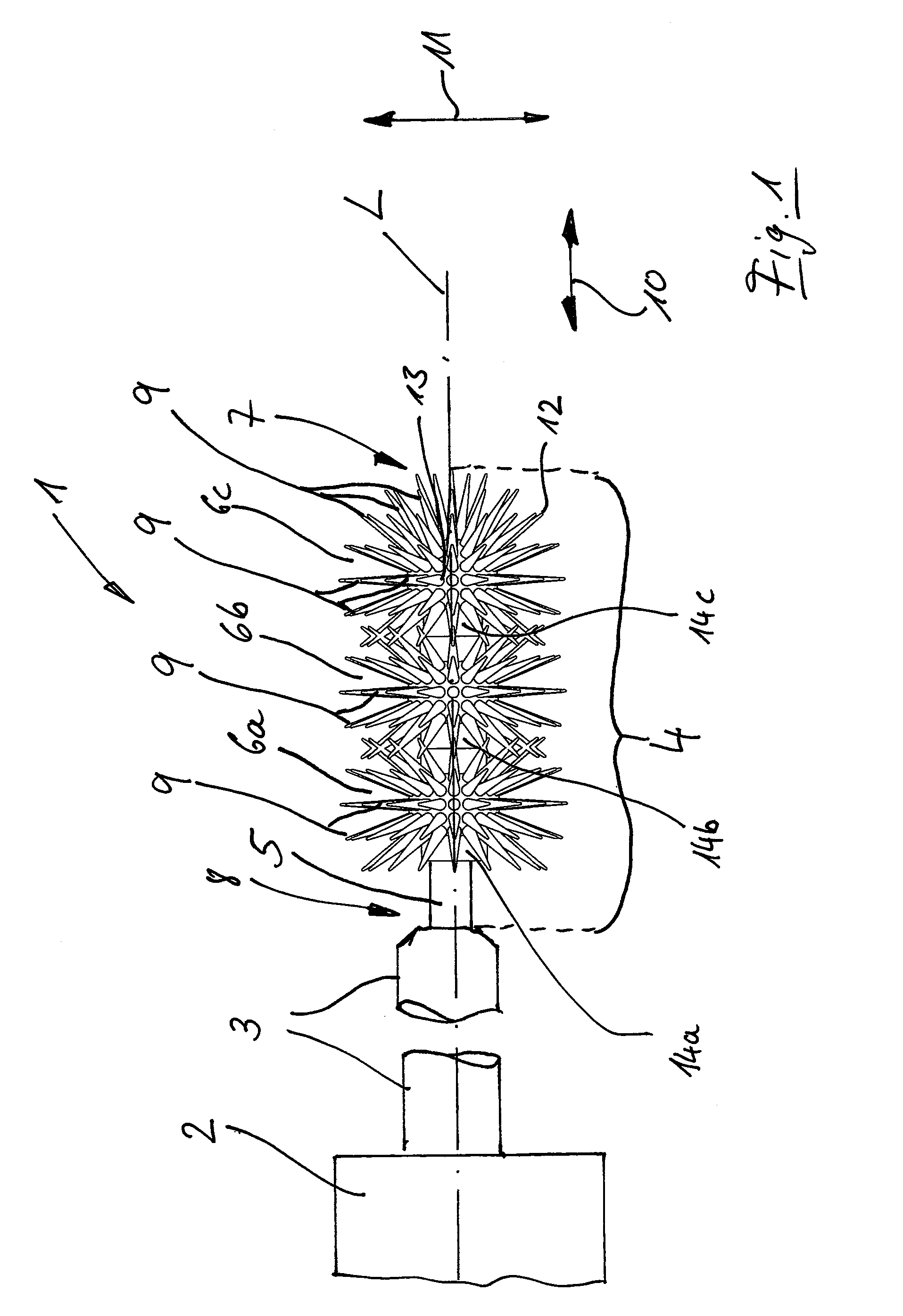

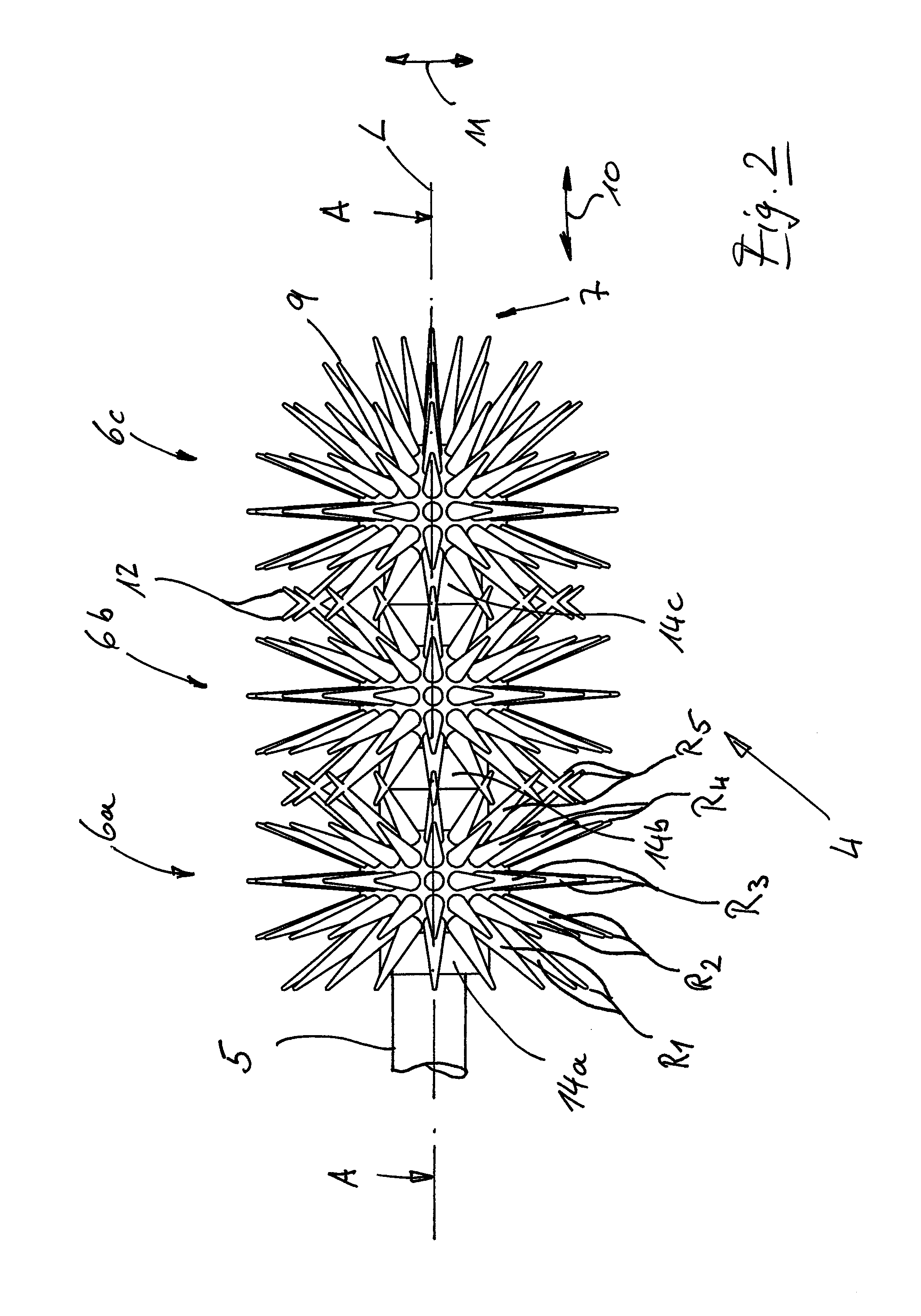

[0063]Hereinafter, the structure of an applicator element 6a, 6b according to the invention will be described with reference to the illustration according to FIG. 3.

[0064]These applicator elements 6a, 6b comprise the base part 14a, 14b. The base part 14a, 14b has an axial longitudinal extent l and is configured, for example, as a tubular-cylindrical body with a through opening 15. An annular groove 15a provided for axially fixing the applicator elements 6a, 6b on the carrier part 5—as is described further below—is disposed in the through opening 15. In a region that is preferably central with respect to the longitudinal extent l, the base part 14a, 14b comprises a bead-like thickened portion 16. The thickened portion 16 is, for example, a ball-like thickened portion 16 with an outer surface 17, from which the bristles 9 protrude approximately perpendicularly with their central axes 9′.

[0065]All the free ends 12 of the bristles 9 of an applicator element 6a, 6b span an imaginary enve...

second embodiment

[0077]FIG. 5 shows an applicator element 6c according to the invention, which is particularly suitable as an applicator element 6c in the region of the distal end 7 of the applicator device 4. Towards the proximal end 8 of the applicator device 4, the applicator element 6c is configured exactly like the applicator elements 6a, 6b with regard to the configuration of the base part 14c and with regard to the bristle covering BF. In contrast to these applicator elements 6a, 6b, the applicator element 6c comprises in the area of the distal end 7 another bristle covering, so that the distal end 7 of the applicator device 4 itself can also be used as an end-face applicator, because a dense bristle covering is provided at the end face.

[0078]In further contrast to the applicator elements 6a, 6b, the applicator element 6c comprises a tapped recess 15b, which also comprises an annular groove 15a, instead of the through opening 15. With the tapped recess 15b, the applicator element 6c—as is des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com