Friction lining carrier plate

a technology of friction lining and carrier plate, which is applied in the direction of friction lining, actuators, brake types, etc., can solve the problems of high weight of friction lining carrier plate and thick sheet steel, and achieve the effect of reducing the amount of friction lining, less friction lining material, and reducing the total weight of friction lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

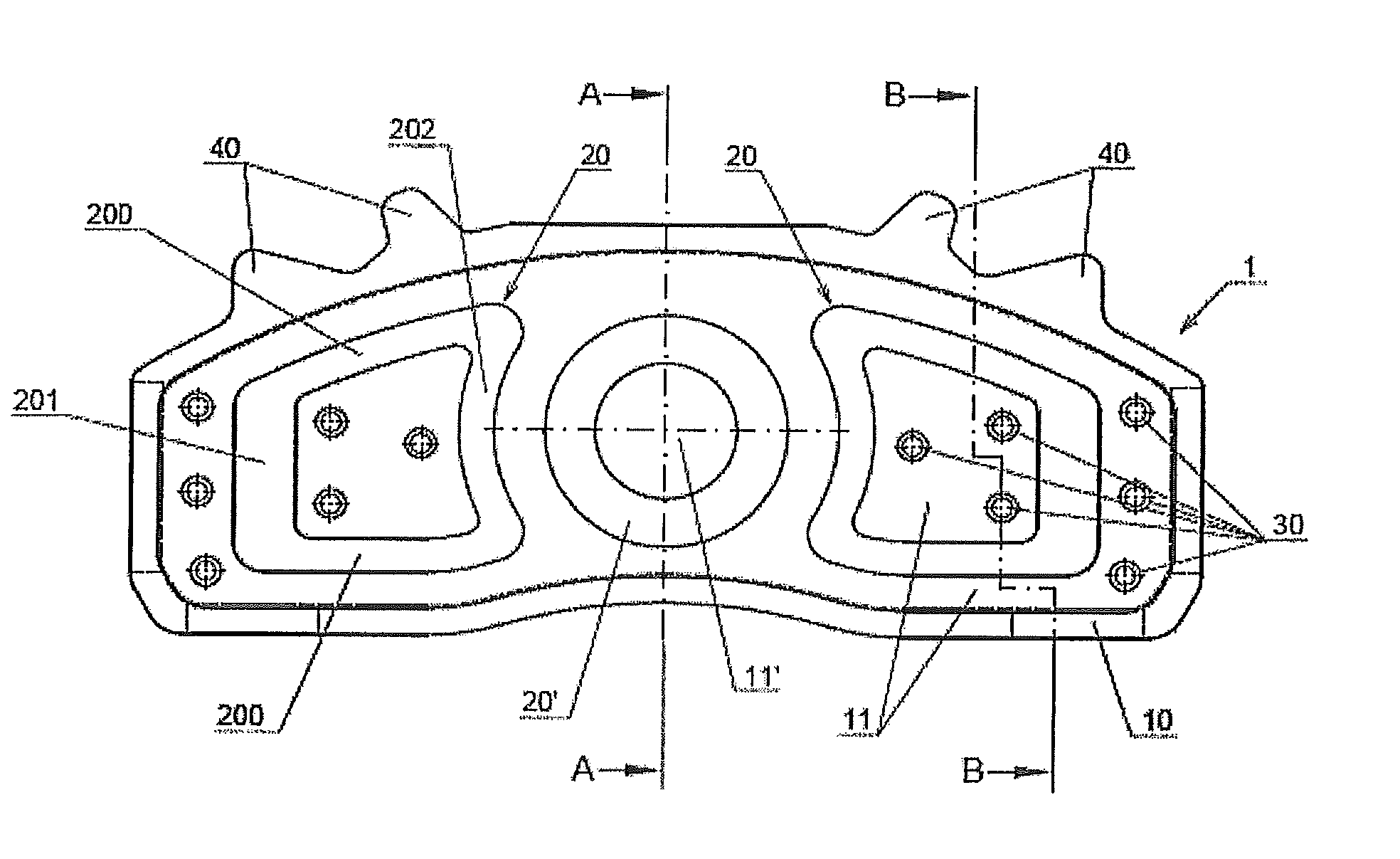

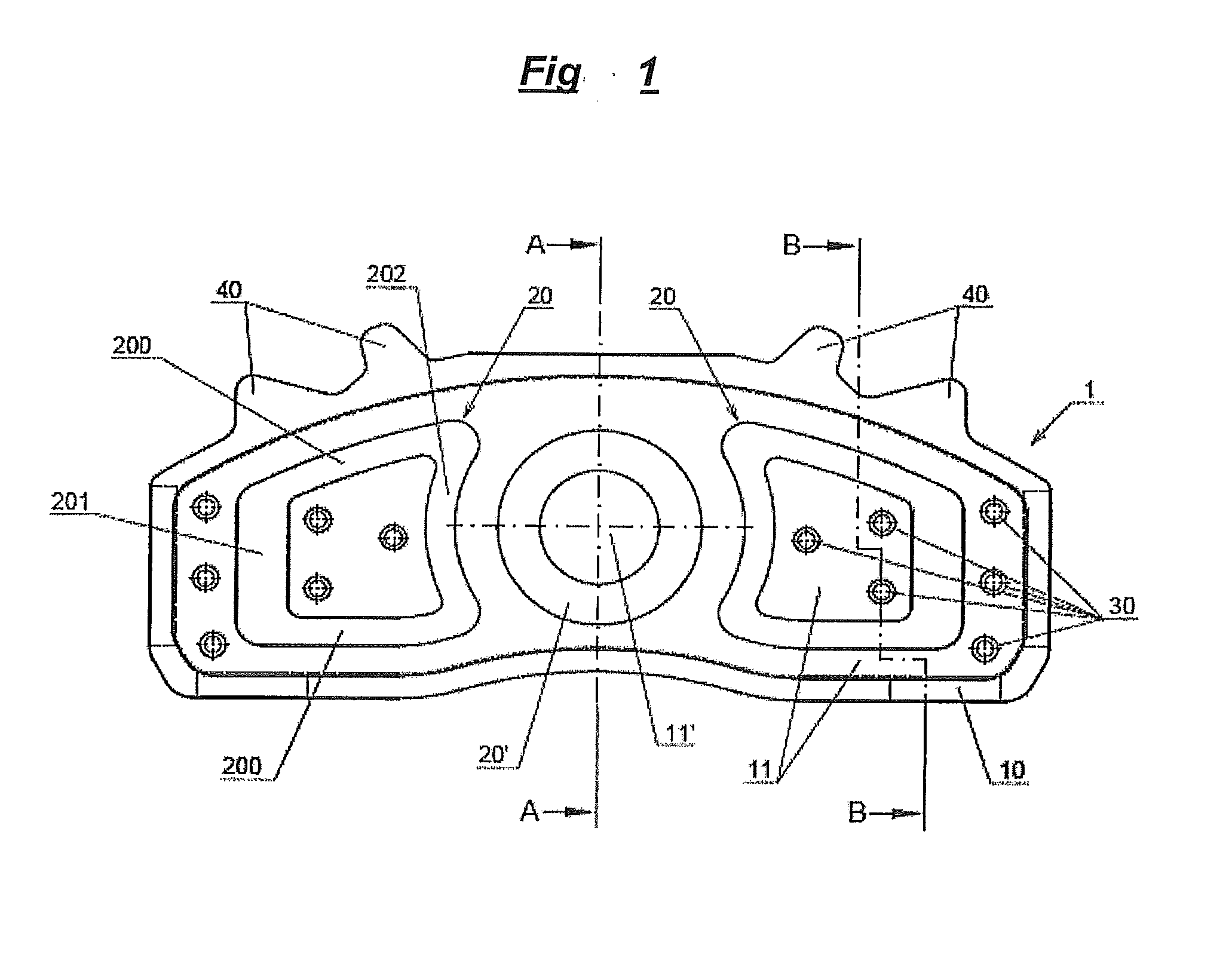

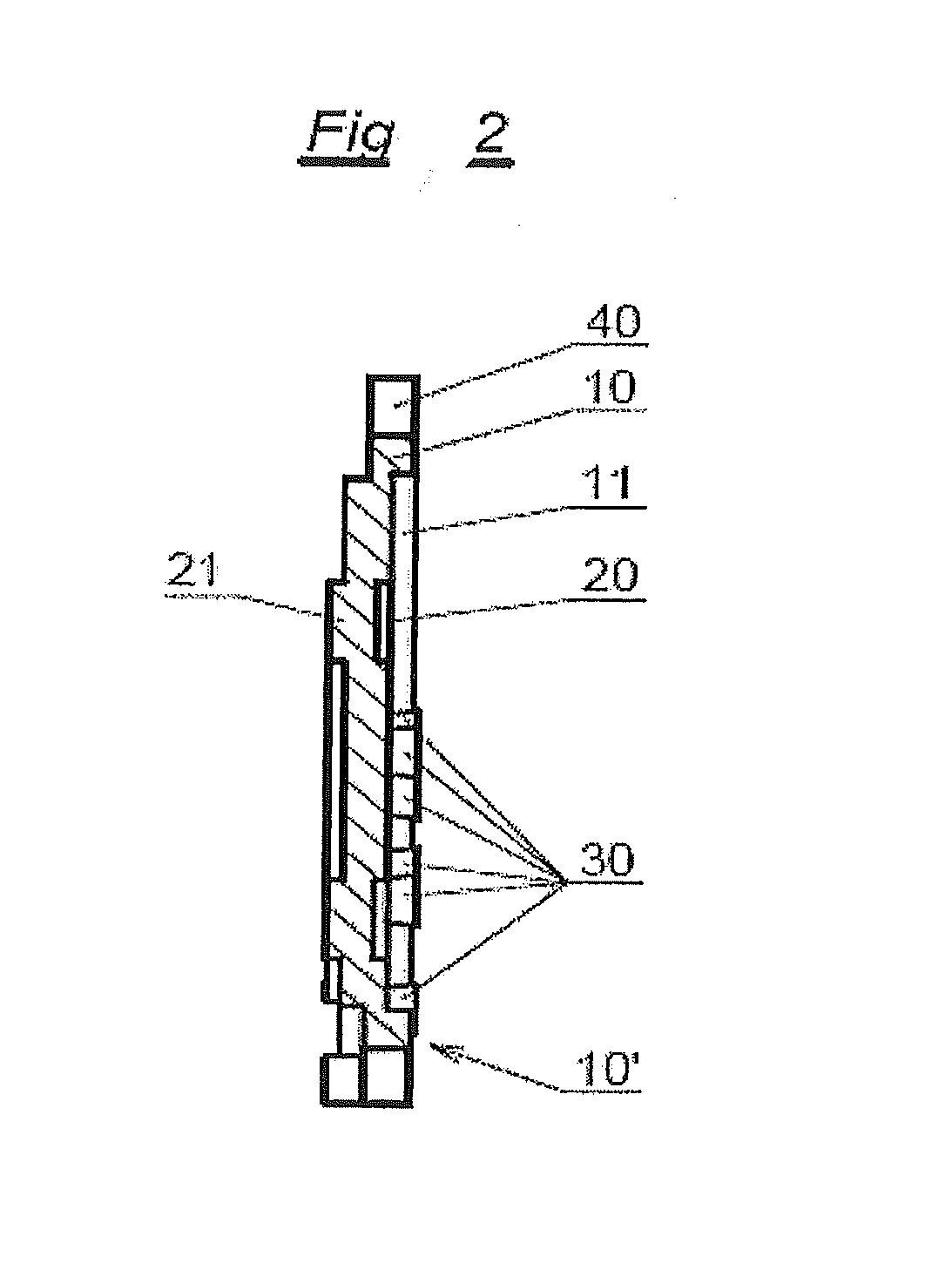

[0037]The friction lining carrier plate 1 shown in FIG. 1 has several fastening means 40 for fastening the friction lining carrier plate 1 to a brake system (not shown here). Moreover, on the side where the friction lining is located, the friction lining carrier plate 1 has a web 10 that runs along the edge of the friction lining carrier plate, a first depression 11 and two differently configured depressions 20, 20′. The web 10 extends from the first depression 11 in the direction away from the rear of the friction lining carrier plate 1. Moreover, the friction lining carrier plate 1 has several projections 30 which extend from the bottom of the first depression 11 in the direction away from the rear of the friction lining carrier plate 1.

[0038]A second depression 20′ is configured so as to be circular and it surrounds a circular first depression 11′. The width of the second circular depression 20 is constant and preferably amounts to 10 mm. The circular second depression 20′ is arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com