System and method for cooling and extraction of heavy ashes with increase in total boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

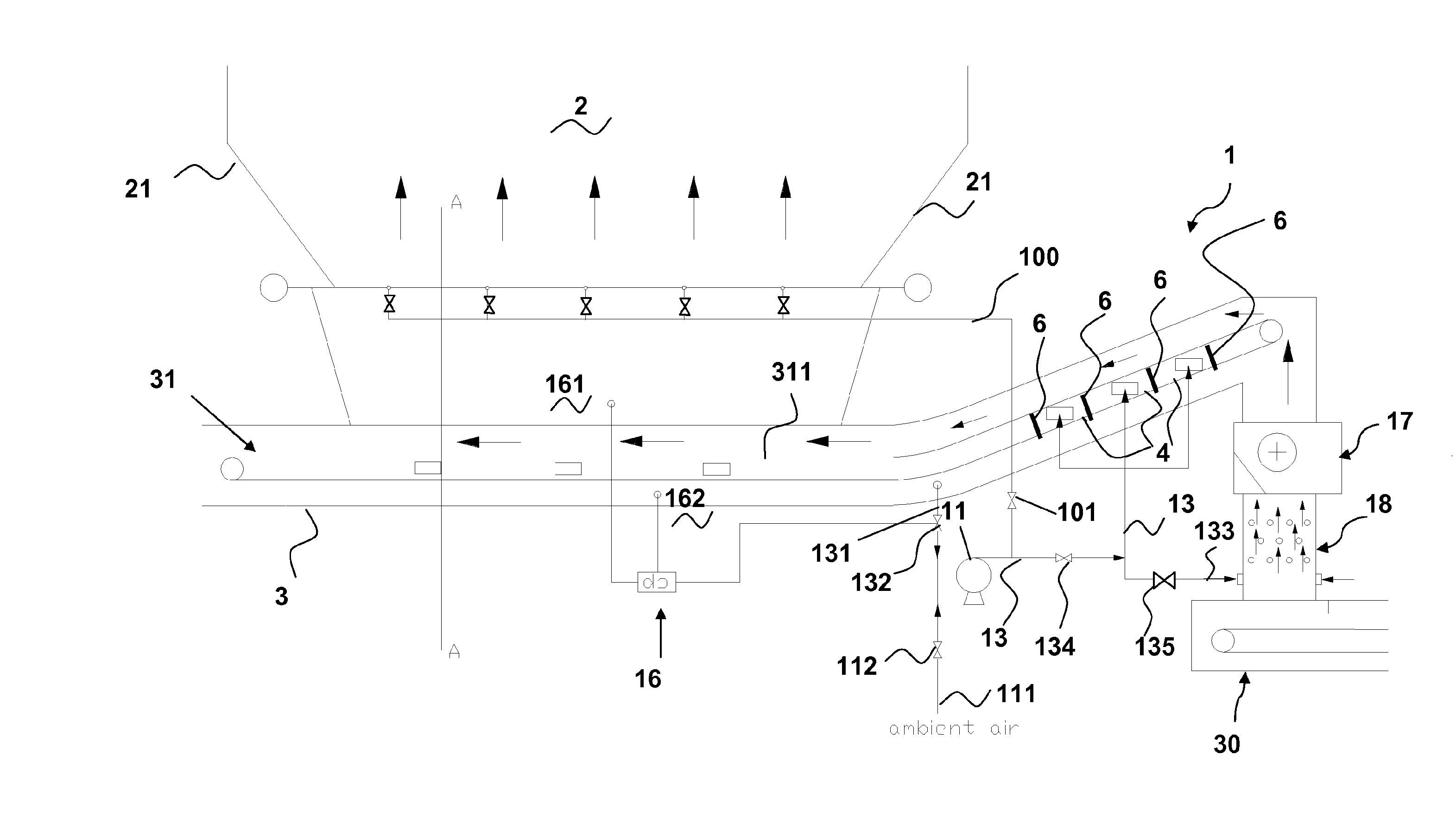

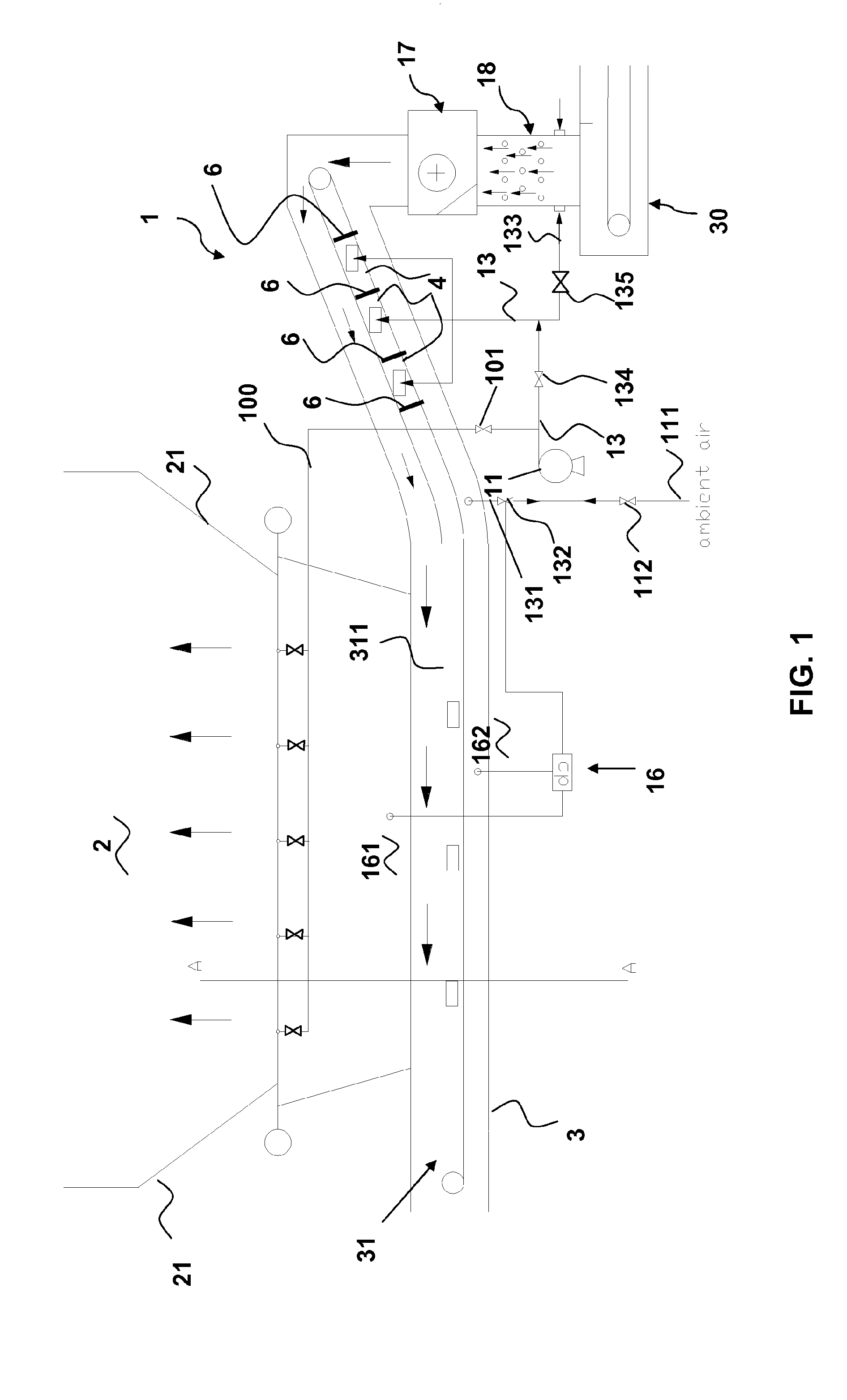

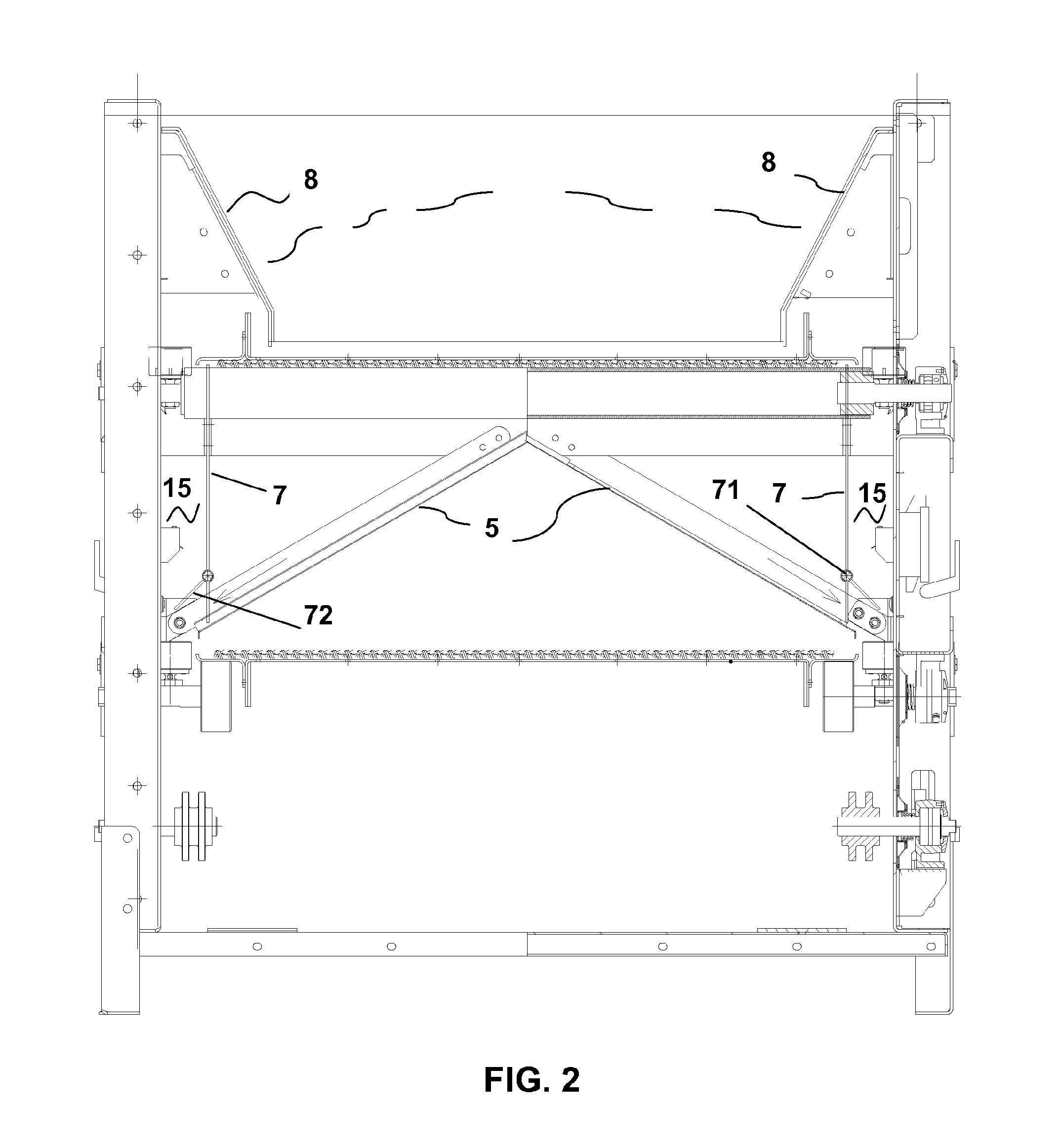

[0052]In a first embodiment shown in FIGS. 2 and 2A, the partitioned region 4 is affected by transverse baffles 6, arranged transversely to the transport surface 311 with respect to the direction of this advancement, and bounded laterally by two longitudinal baffles 7, spanning according said progress direction.

[0053]The lateral baffles 7 are arranged near the transport surface 311 and its roller support 14, so as not to interfere with the movement of each body but at the same time minimizing light outflows through the air cooling alleged in the partitioned region 4.

[0054]In addition, the arrangement of the transverse baffles 6 of the partitioning of the region below the transport surface 311 ensures a labyrinth seal to the cooling air, assisting the sealing action to the lateral air outflows by means of baffles 7.

[0055]Always in this example, the partitioned region 4 is bounded below by a tilted-surface plate 5 for recovering of any lost fines during the transport on the surface 31...

second embodiment

[0056]In the partitioned region 4 shown in FIGS. 3, 3A, transverse baffles 6 are still provided, in this case associated with bulkheads or lateral baffles 51 which extend longitudinally along the belt 31, substantially parallel to it, upper to the transport surface 311 and each along a respective side of this, where the contact or proximity of said baffles 51 with the containment ends 81 of the transport belt 31, allows limiting the passage of air that does not pass through the hole belt 31.

[0057]In this second embodiment, each of the tilted-surface plate 5 presents a lower end door 725 selectively openable to the outside through a mechanism 715, preferably hinged, for the purposes of downflow of fines toward the bottom of said containment casing 3. Thus, when—during normal operation—the door 725 is closed, it keeps a tight air, being in direct contact with the side wall of the casing 3.

[0058]A further embodiment may provide the combined presence of these side walls arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com