Filler neck for filling a fluid system

a fluid system and filling technology, applied in liquid handling, machines/engines, packaging goods types, etc., can solve the problems of high risk of debris from spin welding process of caps, engine or water pump damage, etc., and achieve the effect of avoiding joint breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

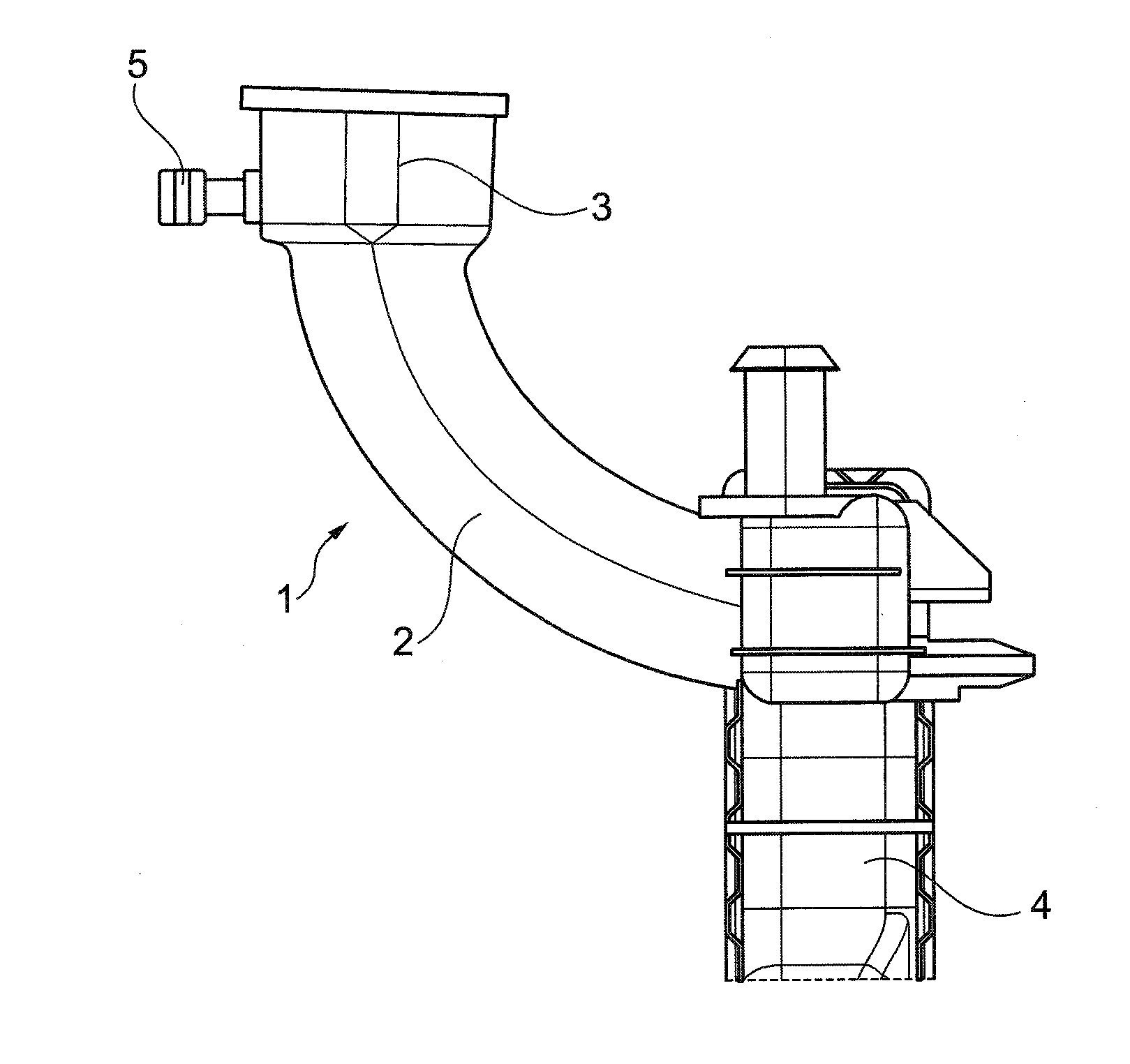

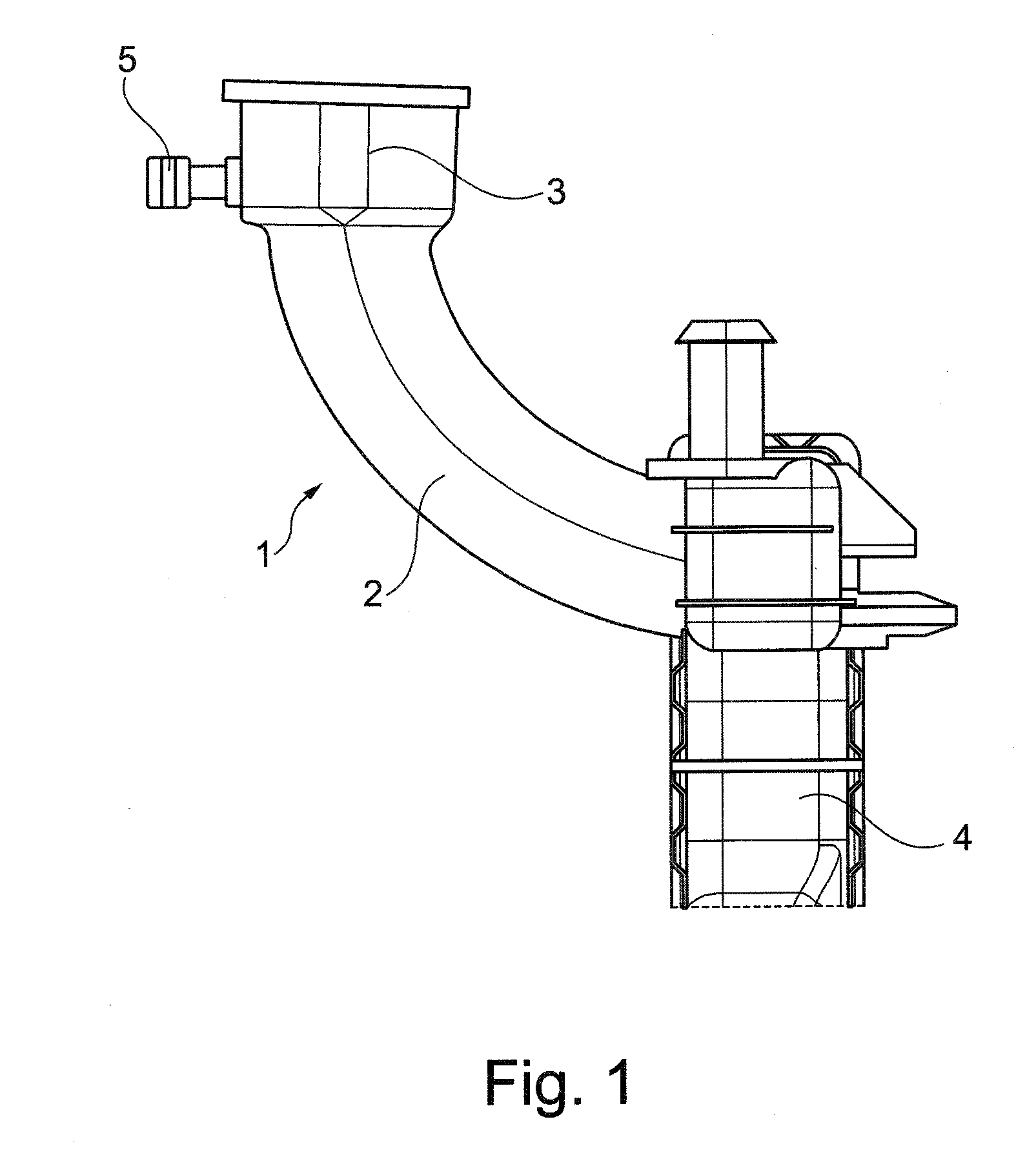

[0016]The figure shows a first embodiment of the filler neck 1 according to the invention. Such a filler neck 1 is used by filling a fluid system with fluid. Such fluid systems are especially radiator assemblies or engine coolant systems, which are filled with a coolant.

[0017]The filler neck 1 includes a filler tube 2 and a filler beginning 3. The filler tube 2 is arranged on the fluid system 4 wherein the filler tube 2 is curved. Hence, the filler beginning 3, which is designed at the filler tube 2 opponent to the fluid system 4, is directed perpendicularly to an opening of the fluid system 4 not depicted in addition. Laterally, a flanged socket 5 extends to the filler beginning 3. The diameter of the filler beginning 3 is larger as the diameter of the filler tube 2.

[0018]The whole filler neck 1 comprises the filler tube 2, the filler beginning 3 and the flanged socket 5 and is fabricated as one piece. Advantageously, the filler neck is formed of plastic material. The filler neck 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| radius of curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com