Method for forming metal member on casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

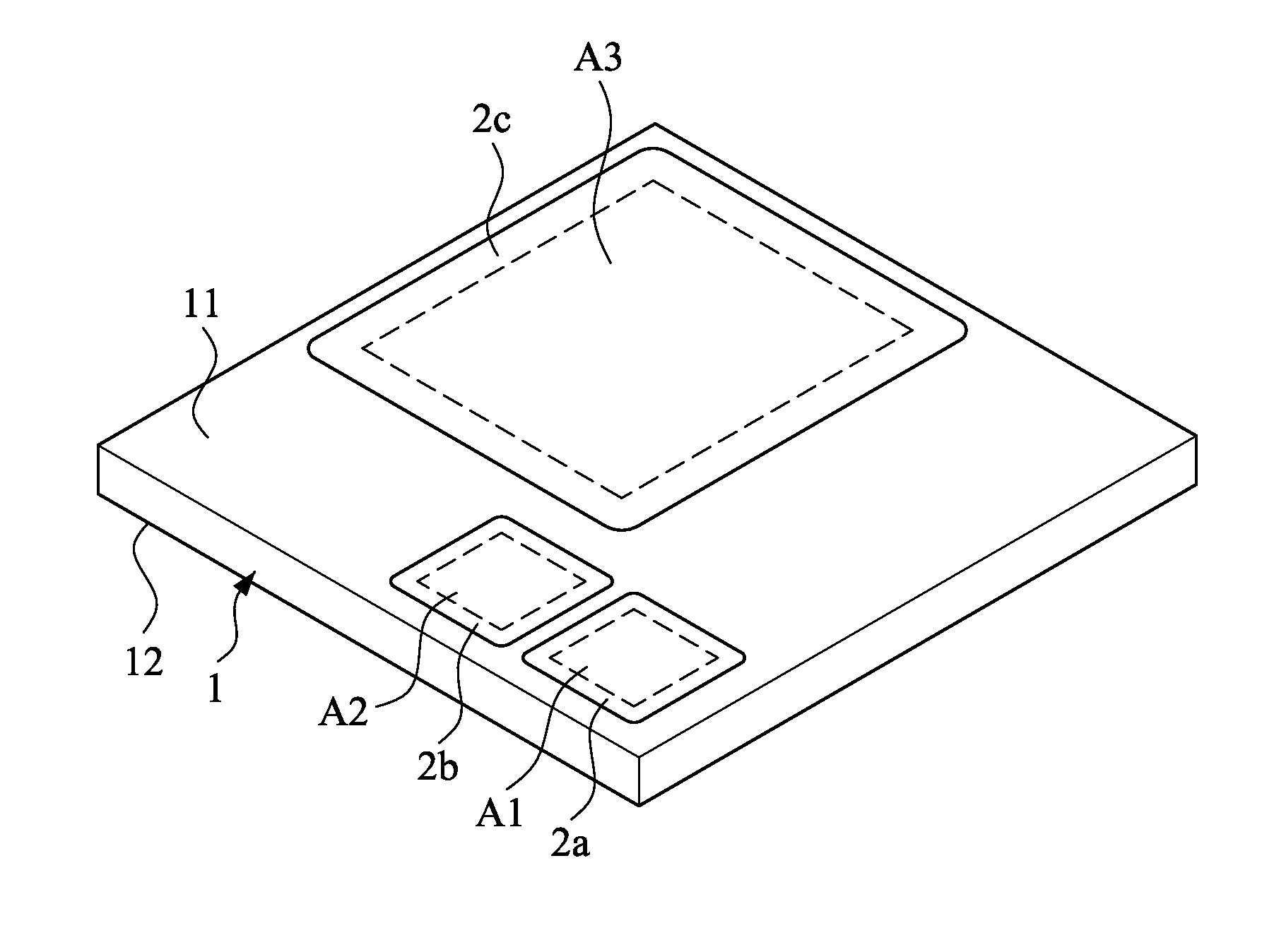

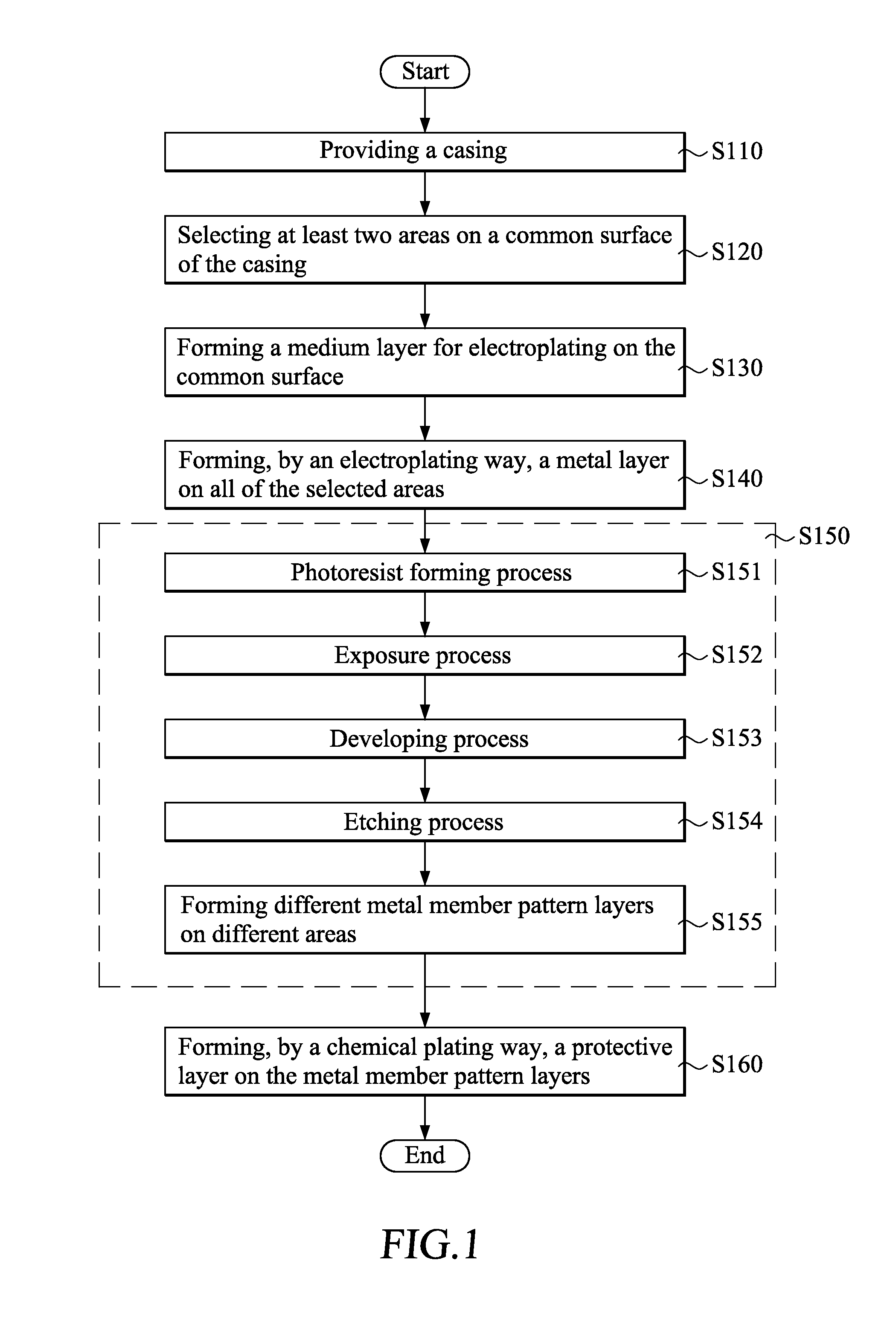

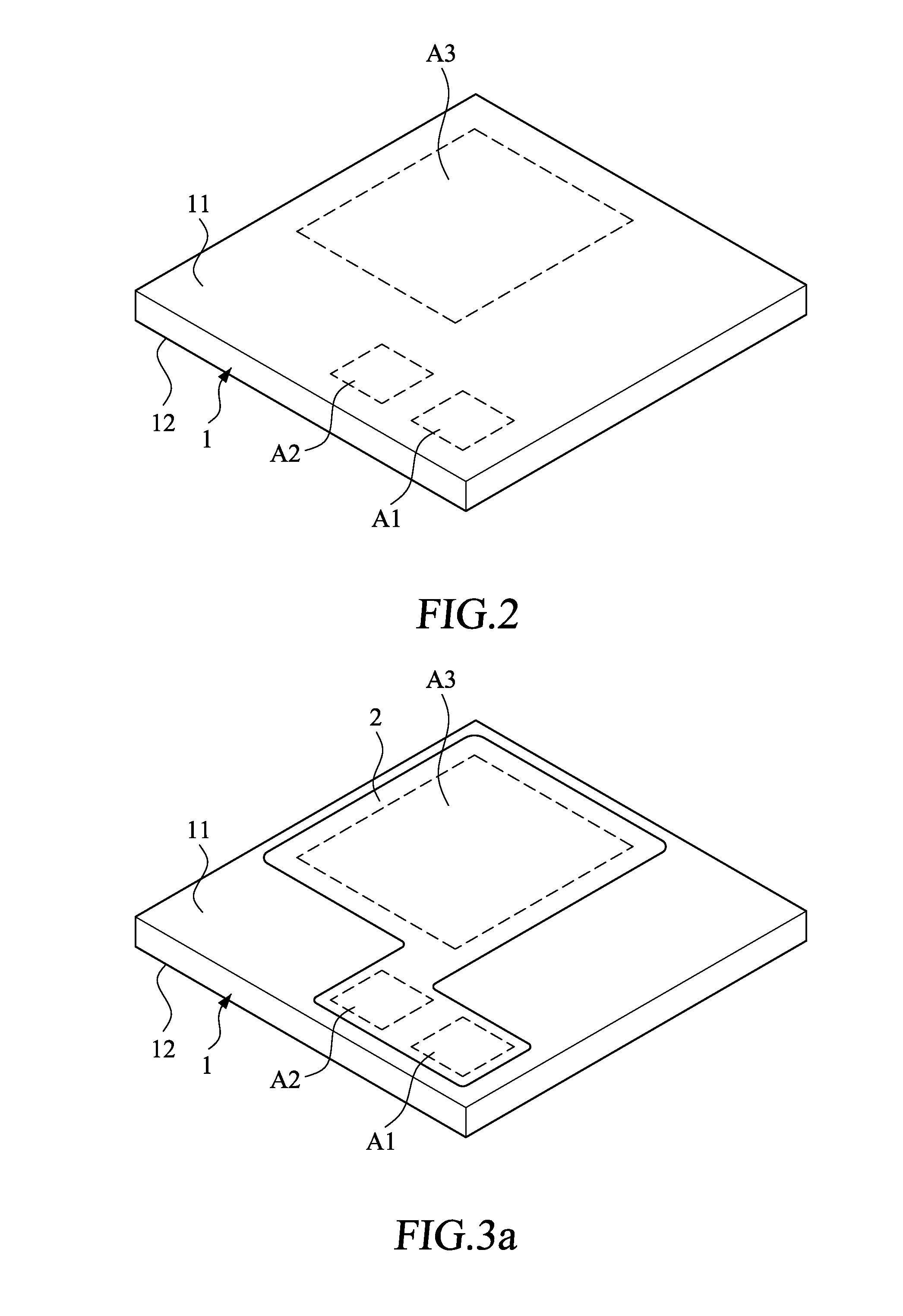

[0019]Please refer to FIGS. 1-4. FIG. 1 is a flow chat of a method for forming metal members on a casing of an embodiment according to the present invention; and FIGS. 2-4 are stereographic views illustrating forming metal members on a casing by the method according to the present invention.

[0020]Firstly, a casing 1 of an electron device is provided (step S110). As an example, the electron device (not shown) may be a notebook computer, a tablet computer, or a mobile phone. In this embodiment, the casing 1 is made of an insulating material, such as plastics.

[0021]Next, as shown in FIG. 2, at least two areas on a common surface of the casing 1 are selected (step S120). Generally, the casing 1 has an inner side surface 11 and an outer side surface 12, wherein the inner side surface 11 is referred to a surface which faces to the inner side of the electron device, and the outer side surface 12 is referred to a surface which faces to outside of the electron device. In this step, it is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com