Separation method for potassium from aqueous koh solutions

a potassium hydroxide and aqueous technology, applied in the direction of water/sewage treatment by neutralisation, alkali metal carbonates, alkali metal halide purification, etc., can solve the problems of industrial waste water removal of certain harmful chemicals, continue to plague industry and government, etc., and achieve the effect of efficient precipitation and greater separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

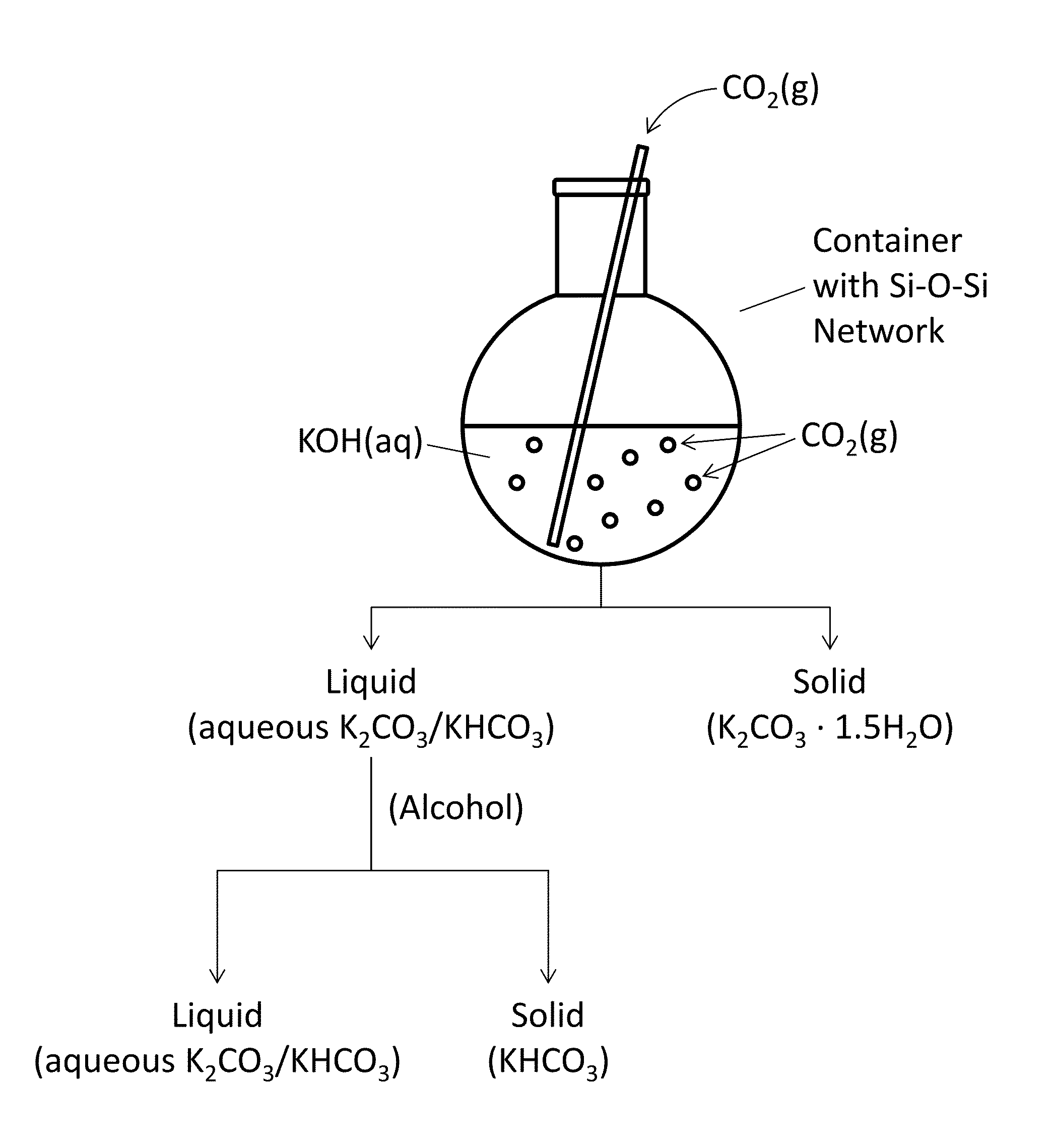

Method used

Image

Examples

example 1

EXAMPLE 1

[0031]KOH Waste Stream Treatment

[0032]From a pressurized CO2 cylinder, via a manifold, three batches (200 mL, 1 L, and 3 L) of a waste KOH sample were bubbled for three hours. This step of the treatment process was exothermic. From room temperature, the temperatures of the batches rose to 41°, 39° and 31° C. for the 200 mL, 1 L and 3 L volumes, respectively. The pH of the original waste stream was about 13, and after bubbling with CO2 the final pH of the treated batches was between about 7 and about 8. In the original method, which was developed with an aqueous potassium hydroxide solution of 50% concentration, a majority of the potassium would separate as a crystalline solid material (potassium carbonate sesquihydrate) at this step. Here, using an actual waste sample, no crystalline materials were separated at this point. This is reasonable and expected because the original method was developed using an aqueous potassium hydroxide solution of 50% concentration. By contrast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com