Method for Cement Evaluation with Acoustic and Nuclear Density Logs

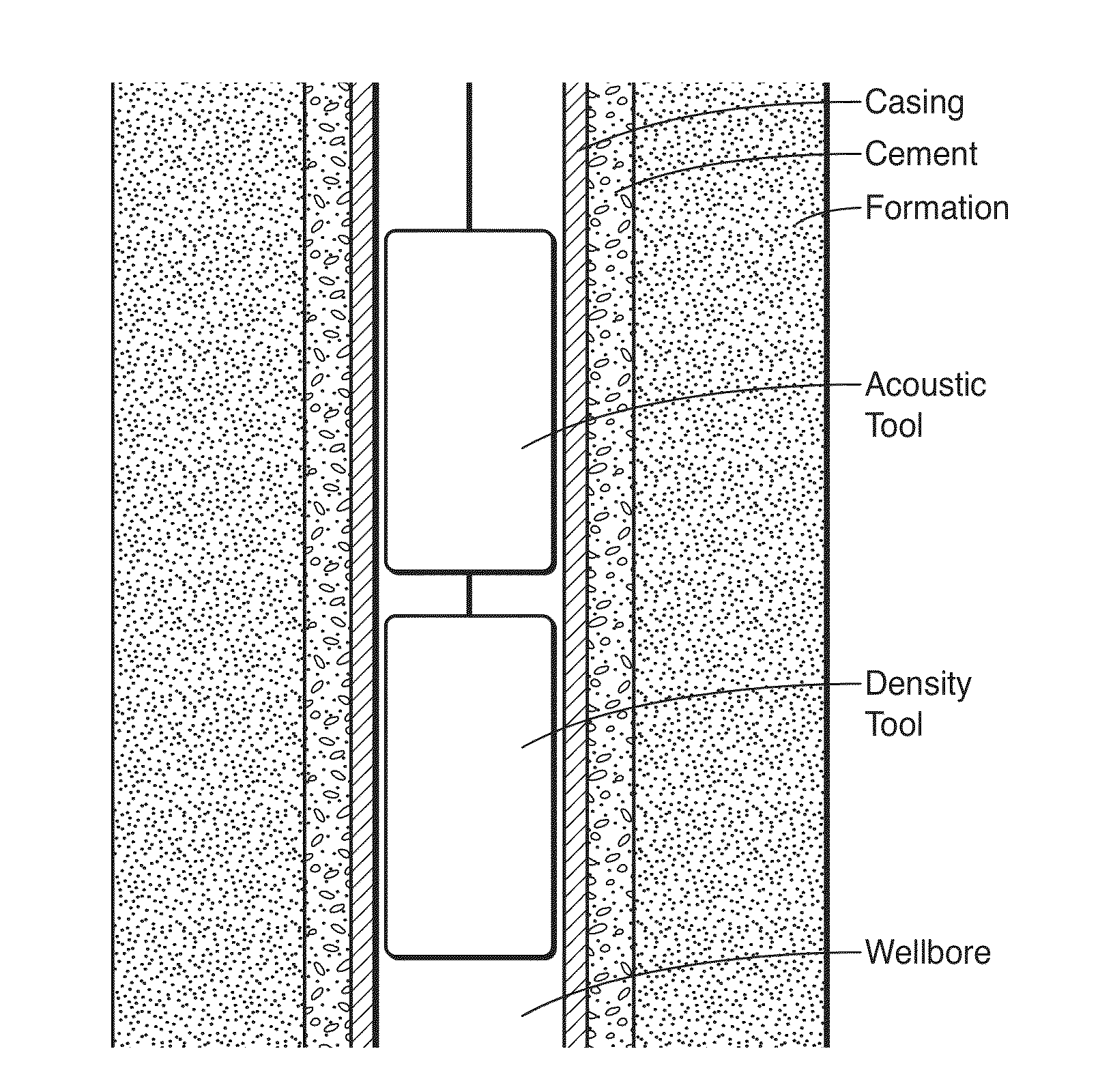

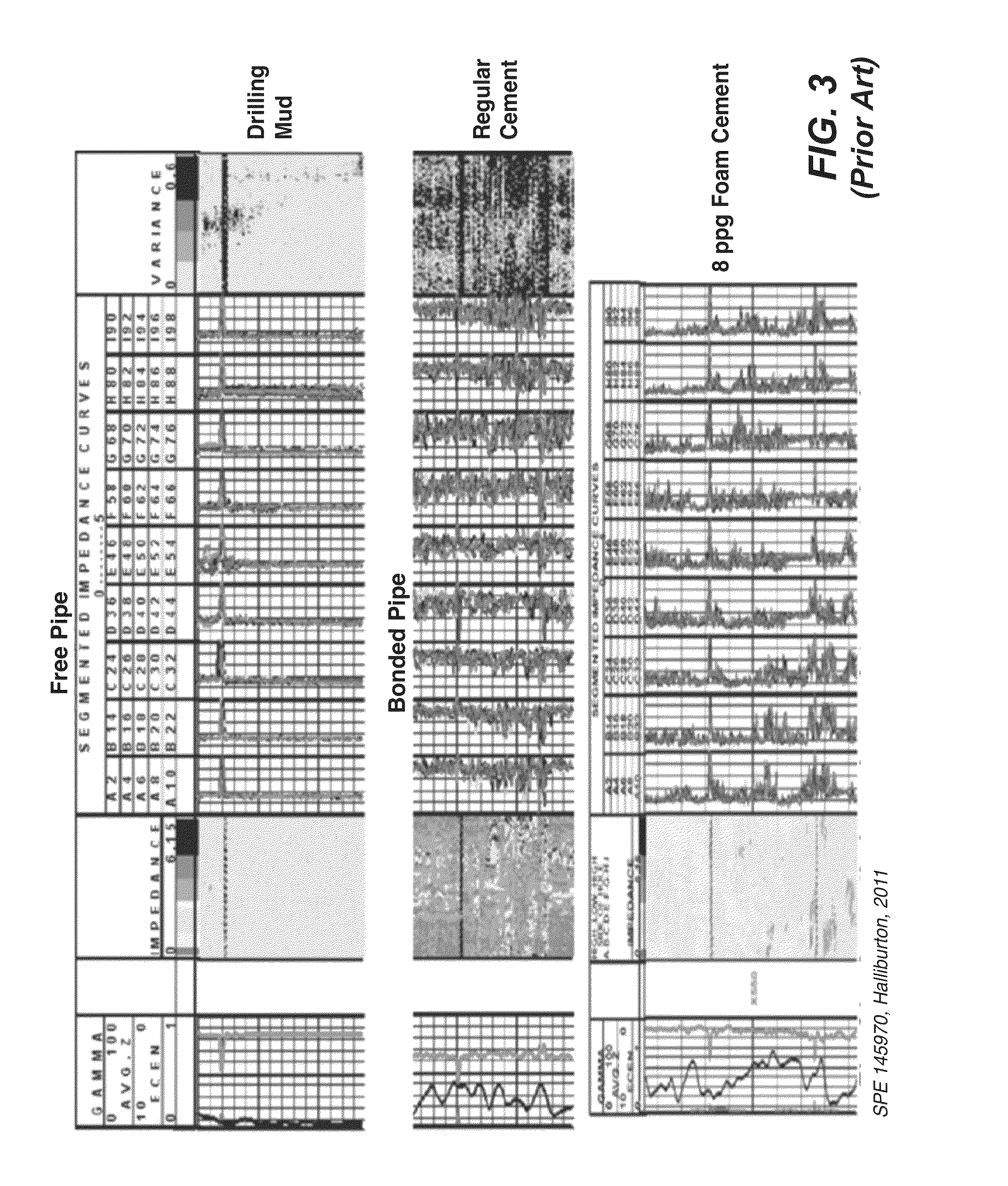

a cement and density log technology, applied in the field of oil or gas production, can solve the problems of fluid contaminated cement, less than ideal, fluid filled channels within the cement sheath,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

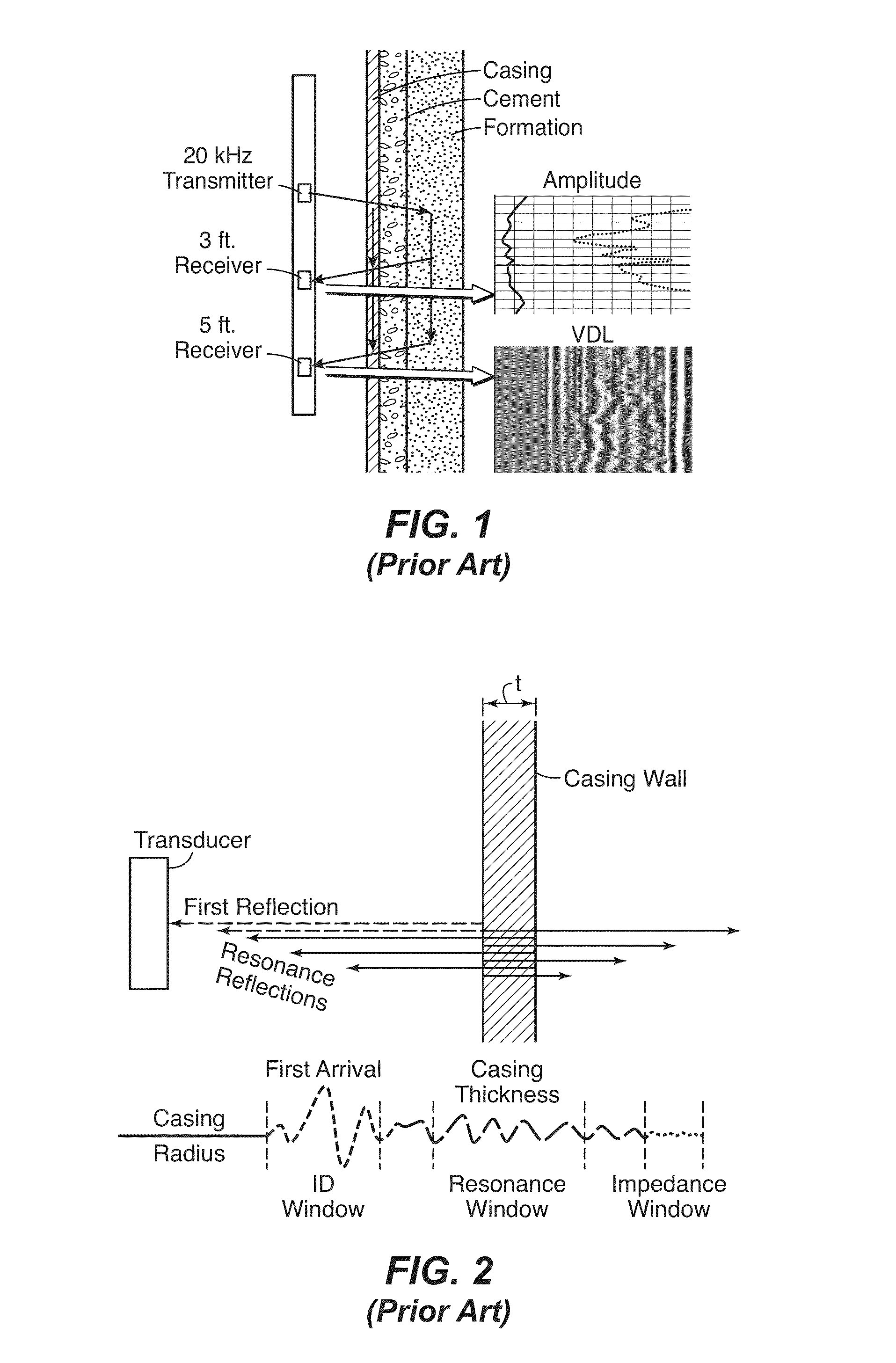

Method used

Image

Examples

examples

[0041]The present inventive method is tested using an ultrasonic modeling software program that simulates the acoustic waveforms 52. A well with fully cemented casing and free pipe was selected to mock up for the modeling study. Actual acoustic data from the subject well was also obtained. The modeling code essentially predicts the field measurements that would result in an actual experiment. The modeled and field ultrasonic waveform data are in good agreement as shown in FIGS. 10 and 11, proving that the modeling code works well. For FIG. 10, a fully cemented well with a good cement bond was modeled and also measured experimentally. FIG. 13 shows a wellbore model with a good cement bond that is very similar to the model in the calculation. For FIG. 11, free pipe (no cement at all) was modeled and measured. FIG. 14 shows a wellbore model with fluid behind casing that is not far off the model used in the FIG. 11 calculation. The waveforms in FIGS. 10 and 11 depict the cement bond qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com