Building Wall Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

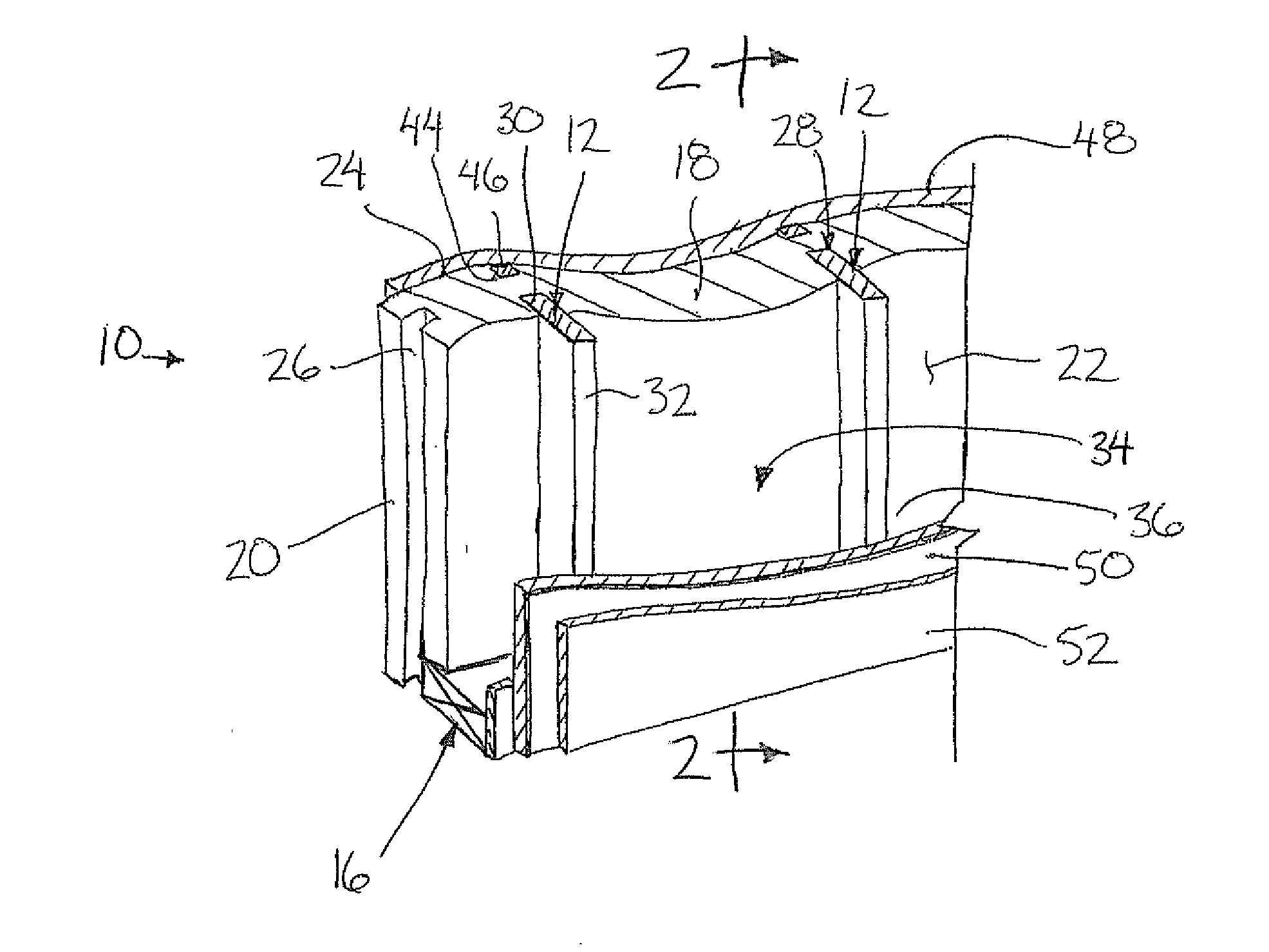

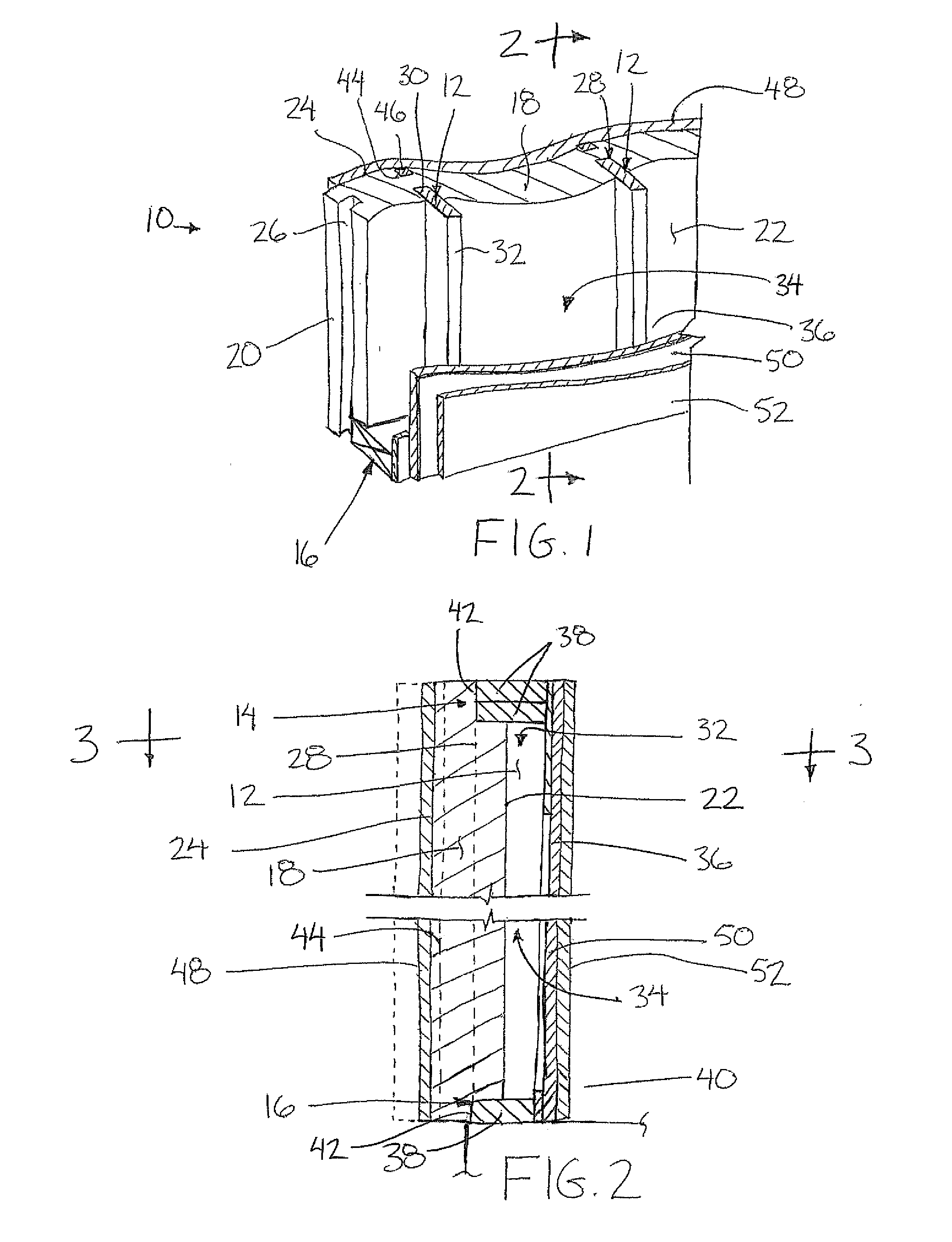

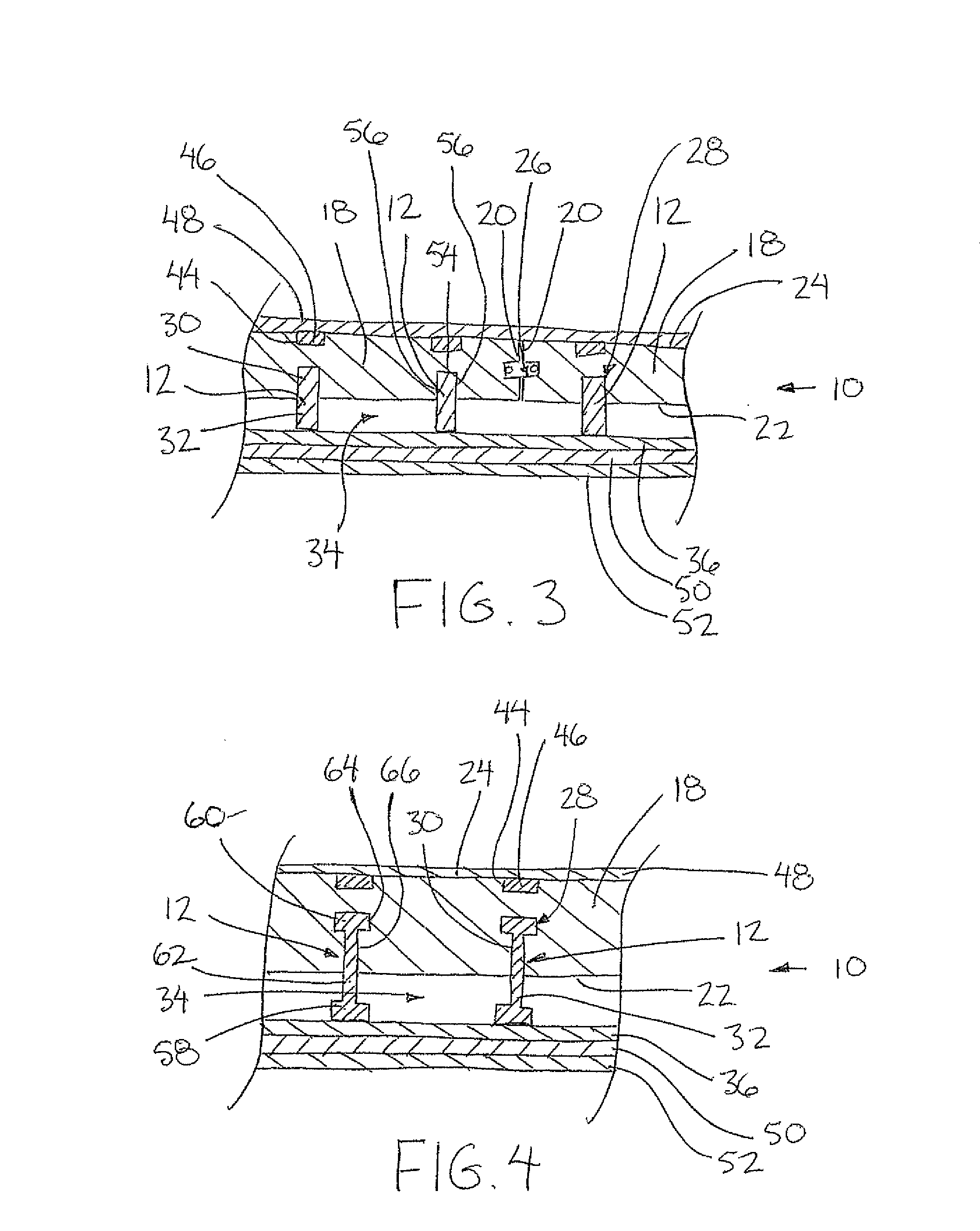

[0047]Referring to the accompanying figures there is illustrated a building wall assembly generally indicated by reference numeral 10. The wall assembly 10 is suited for use as a wall in various buildings including commercial and residential applications.

[0048]The wall assembly 10 includes a plurality of studs 12 which span vertically between a header member 14 at a top end of the wall and a footer member 16 at the bottom end of the wall. The header and footer member extend in the longitudinal direction along the wall so as to span across all of the studs of the wall which are evenly spaced apart in the longitudinal direction by a standard spacing, for example 16 inches between centers.

[0049]The studs may comprise a wooden stud of rectangular cross section as shown in FIGS. 1 through 3, a wooden I-beam construction as shown in FIG. 4, or a metal stud of generally rectangular U-shaped configuration as shown in FIGS. 5 and 6.

[0050]The wall assembly further includes a plurality of insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com