Magnetic-Latch Stabbing Guide

a magnetic latch and stabbing guide technology, which is applied in the direction of drilling casings, drilling pipes, and accessories for wellbores/wells, etc., can solve the problems of affecting the use the hinges the latching mechanism located on the outer surface of the stabbing guide, so as to achieve the effect of convenient use, quick and effective use, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

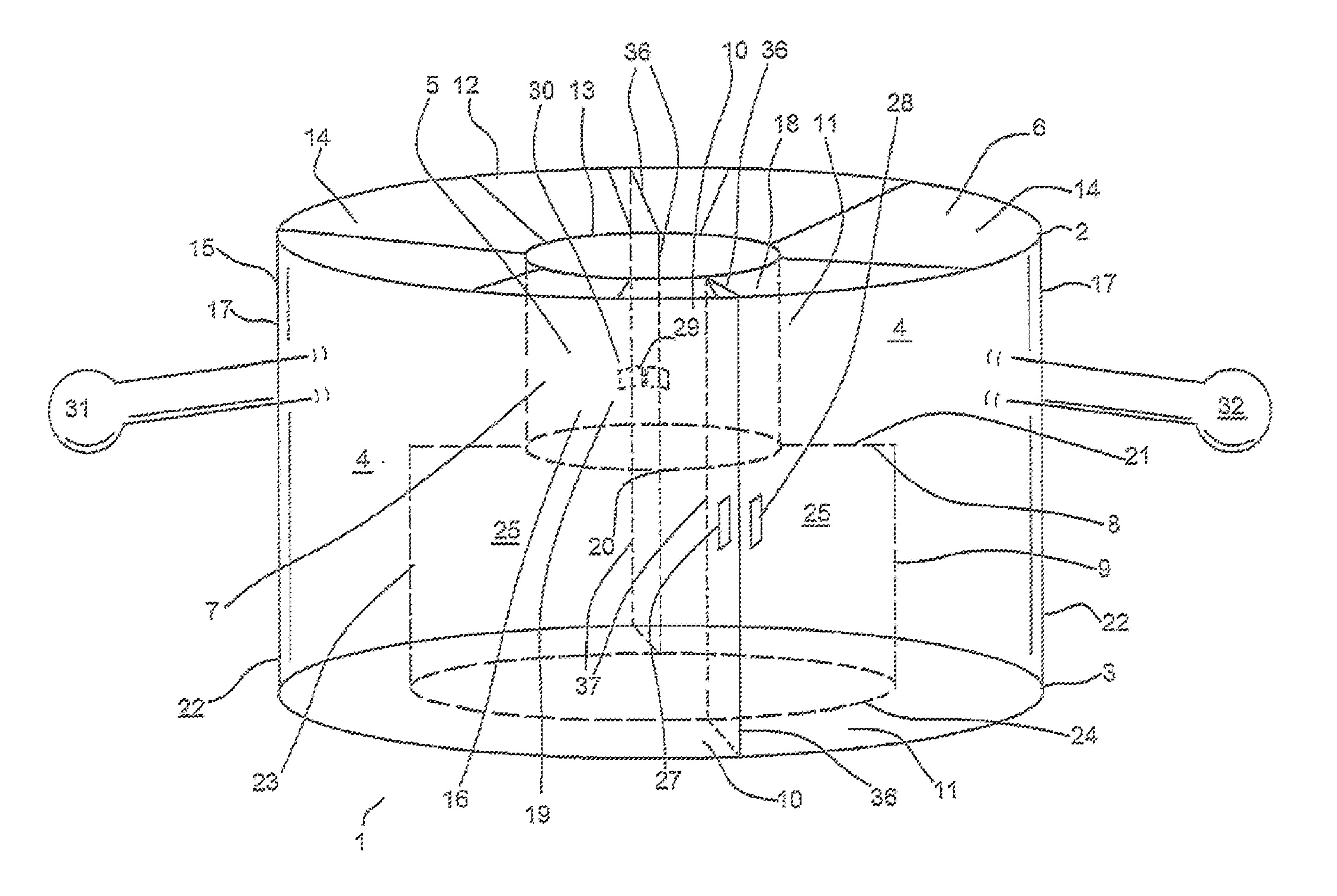

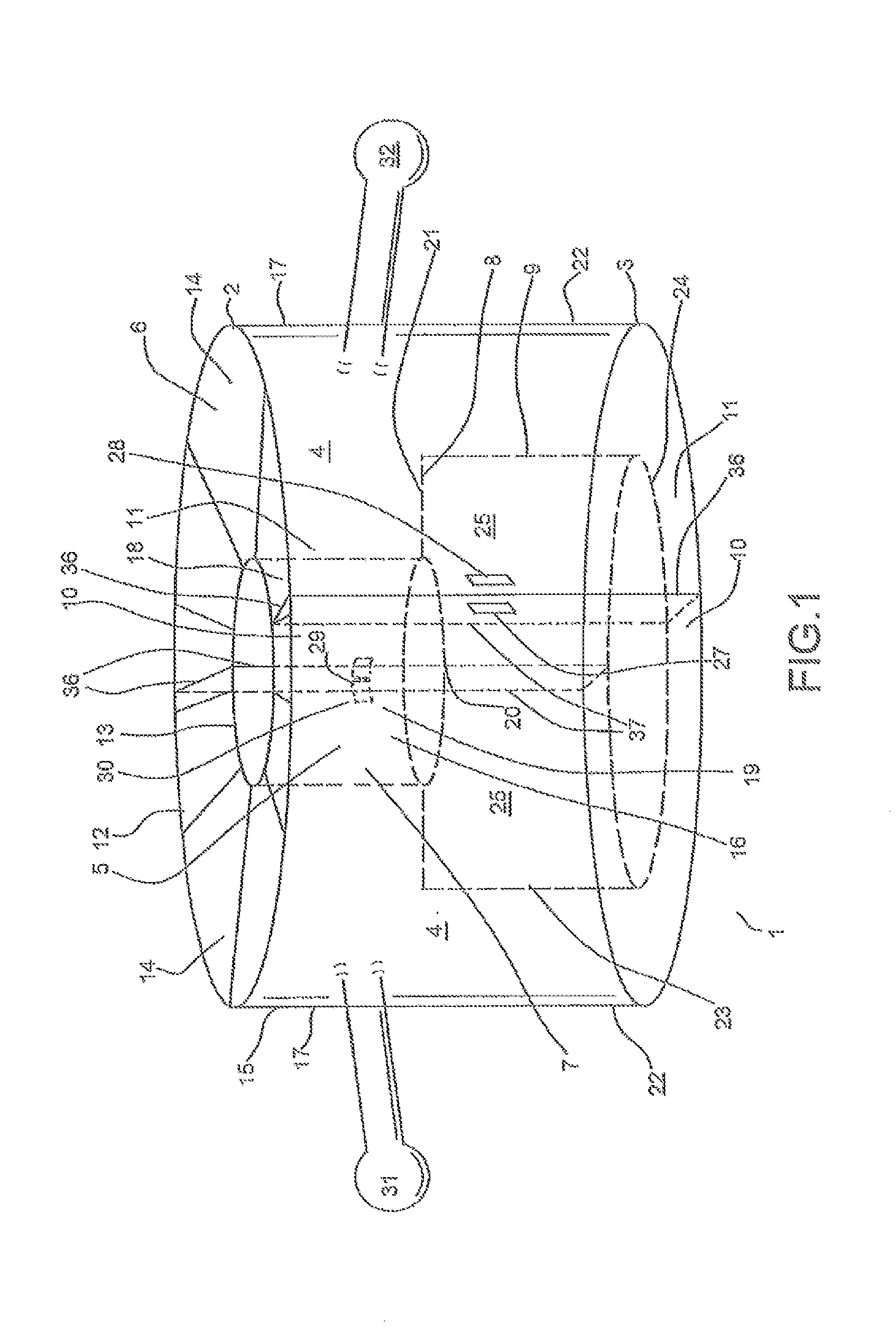

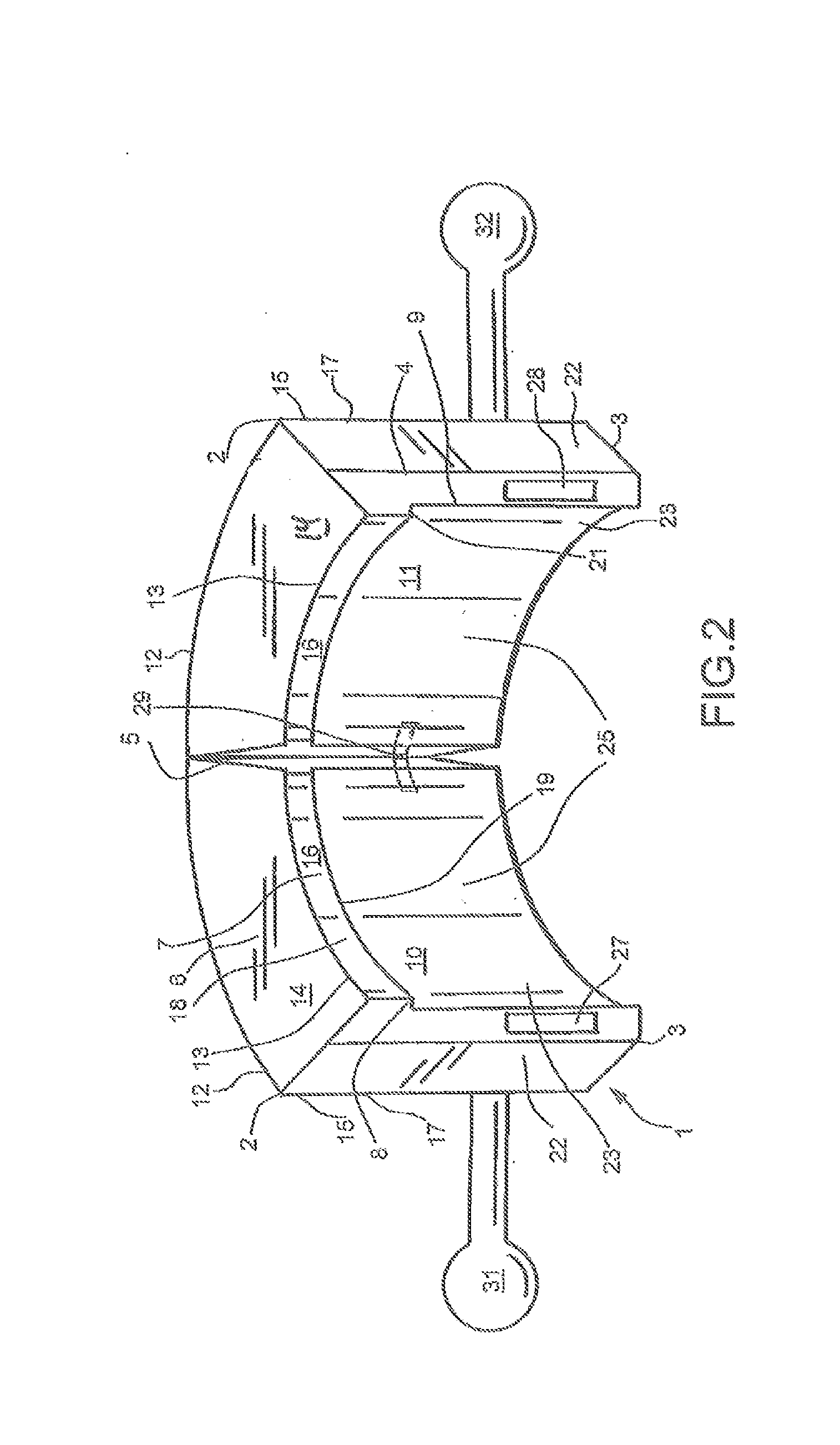

[0016]Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. Throughout the following detailed description, the same reference characters refer to the same or similar elements in all figures.

[0017]FIG. 1 depicts a perspective view of the front of one embodiment of the present invention showing the magnetic-latch stabbing guide 1 in closed position. In one embodiment and as shown in FIG. 1, the magnetic-latch stabbing guide 1 comprises a cylindrical apparatus having a top portion 2 and bottom portion 3. At the guide top portion 2, a funnel-shaped portion 6 is shown. The funnel-shaped portion has a large opening 12 disposed at the very top of the funnel-shaped portion 6. The funnel-shaped portion inner surface 14 connects the large funnel-shaped portion opening 12 to a smaller funnel-shaped portion opening 13. The magnetic-latch stabbing guide 1 further comprises a funnel-shaped portion outer surface 15 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com