Compositions containing biosoluble inorganic fibers and micaceous binders

a technology of micaceous binders and inorganic fibers, which is applied in the field of compositions, can solve problems such as fragile structure and easy breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0102]The following tests were used to characterize the sheet material included in the examples and comparative examples.

Elevated Temperature Shrinkage

[0103]This test was used to determine the shrinkage of sheet material at temperatures that may be seen in a pollution control device. A sample was cut from a sheet using a square die having dimensions of 4.44 cm by 4.44 cm. The sample was measured in the X-Y plane using a dial caliper gauge to determine the area (Abefore heating), and then placed in a Thermalyne Type 48000 furnace that had been pre-heated to 900° C. The sample was heated for 24 hours, 48 hours, or 72 hours as indicated in the test results. After removal from the furnace, the sample was cooled to room temperature and measured with the caliper gauge to determine the area after heating (Aafter heating). The percent shrinkage (% Shrinkage) was determined as follows.

% Shrinkage=[(Abefore heating−Aafter heating) / Abefore heating}]×100

[0104]The sheet material may expand in th...

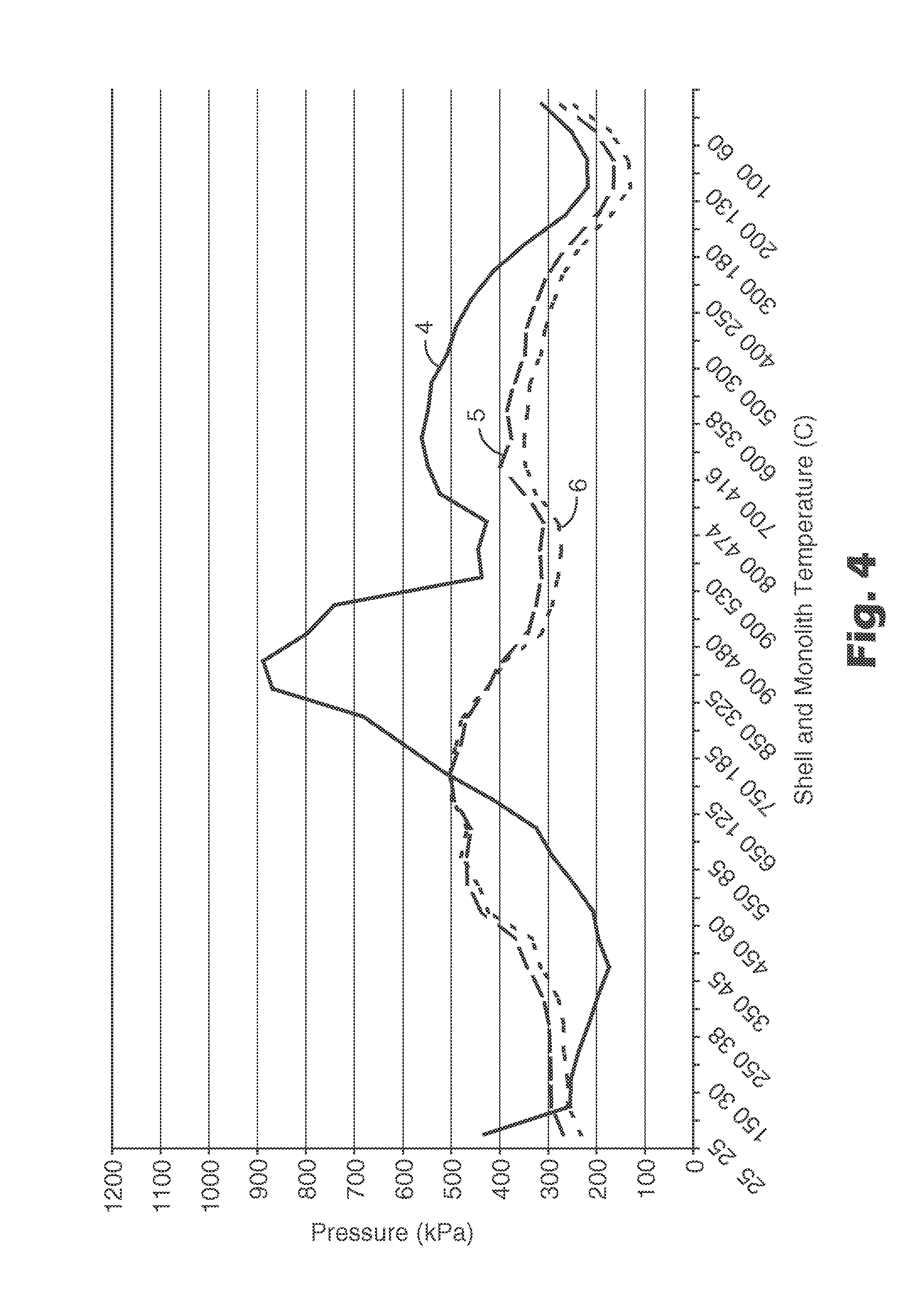

example 5

[0119]A sheet material was prepared as in Example 4 except that the expanded vermiculite was Micron Grade Expanded Vermiculite obtained from The Strong Co., Inc., Pine Bluff, Ark., and 1 gram of 0.635 long rayon fibers (available from Minifibers Inc Johnson City, Tenn.) was added to the slurry with the soluble fibers. A graph of the results is shown in FIG. 4. The mount density was 0.95 g / cc. The sample was held at the peak temperature for 2 hours. The first cycle is shown in plot 4, the second cycle is shown in plot 5, and the third cycle is shown in plot 6. The intumescent mat had acceptable shrinkage and pressures above 100 kPa when tested in the RCFT.

example 6

[0120]A multilayered construction was formed from a layer of dry-laid and needle punched sheet made as described in U.S. Pat. No. 5,290,522 (Rogers, et al.) at about 700 grams per square meter and a layer of intumescent sheet of Example 5 at about 2770 grams per square meter. The two layers were placed together, and the construction was tested in the RCFT (real condition fixture test) with the Example 5 layer placed next to the hot side platen and the dry-laid sheet placed next to the cold side platen. When tested for three temperature cycles as described in Example 5 at a mount density of about 0.7 grams per cubic centimeter but with the maximum platen temperature reaching only 500° C. on the hot platen and 200° C. on the cold platen, a minimum pressure of about 75 kilopascals and a maximum pressure of about 220 kilopascals was observed. These results demonstrate the general utility of using layered constructions of the present invention as mounting systems in a variety of applicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com