Systems and methods for fabricating objects from bulk metallic glass matrix composites using primary crystallization

a technology of metallic glass matrix and composites, applied in the field of fabricating objects from bulk metallic glass matrix composites, can solve the problems of limited viability of engineering materials, limited manufacturing of metallic glasses, and initial limitations of metallic glasses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

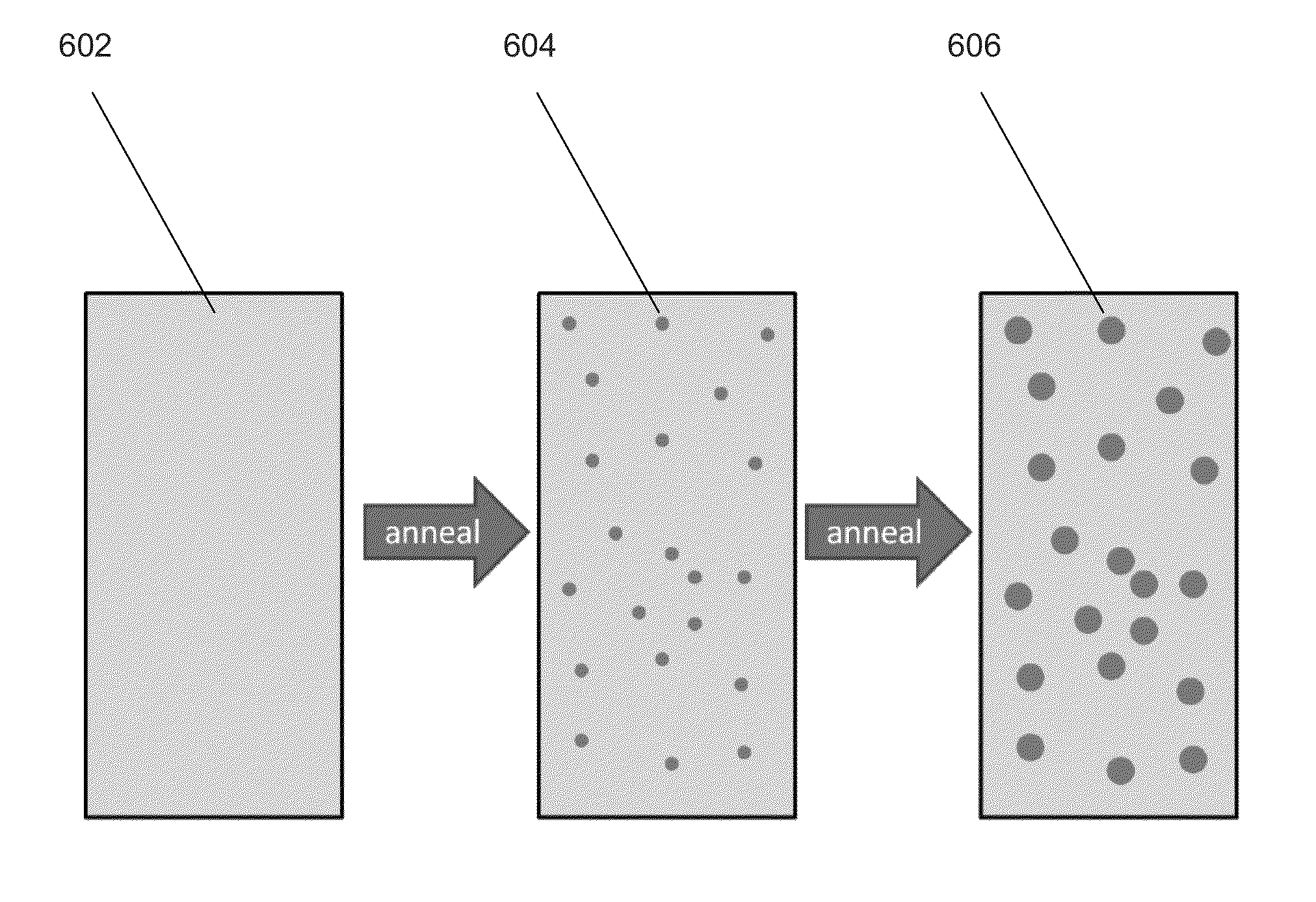

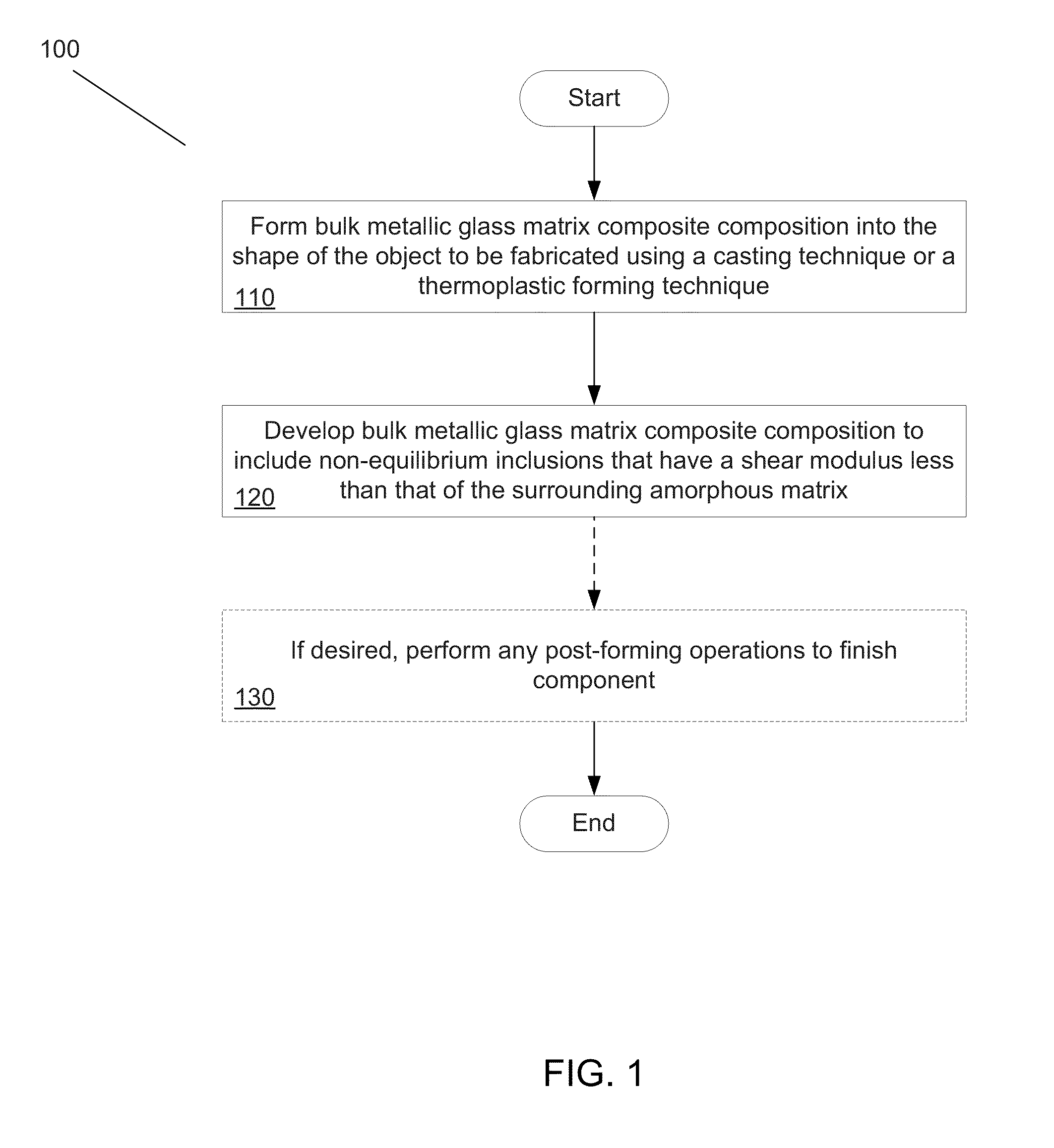

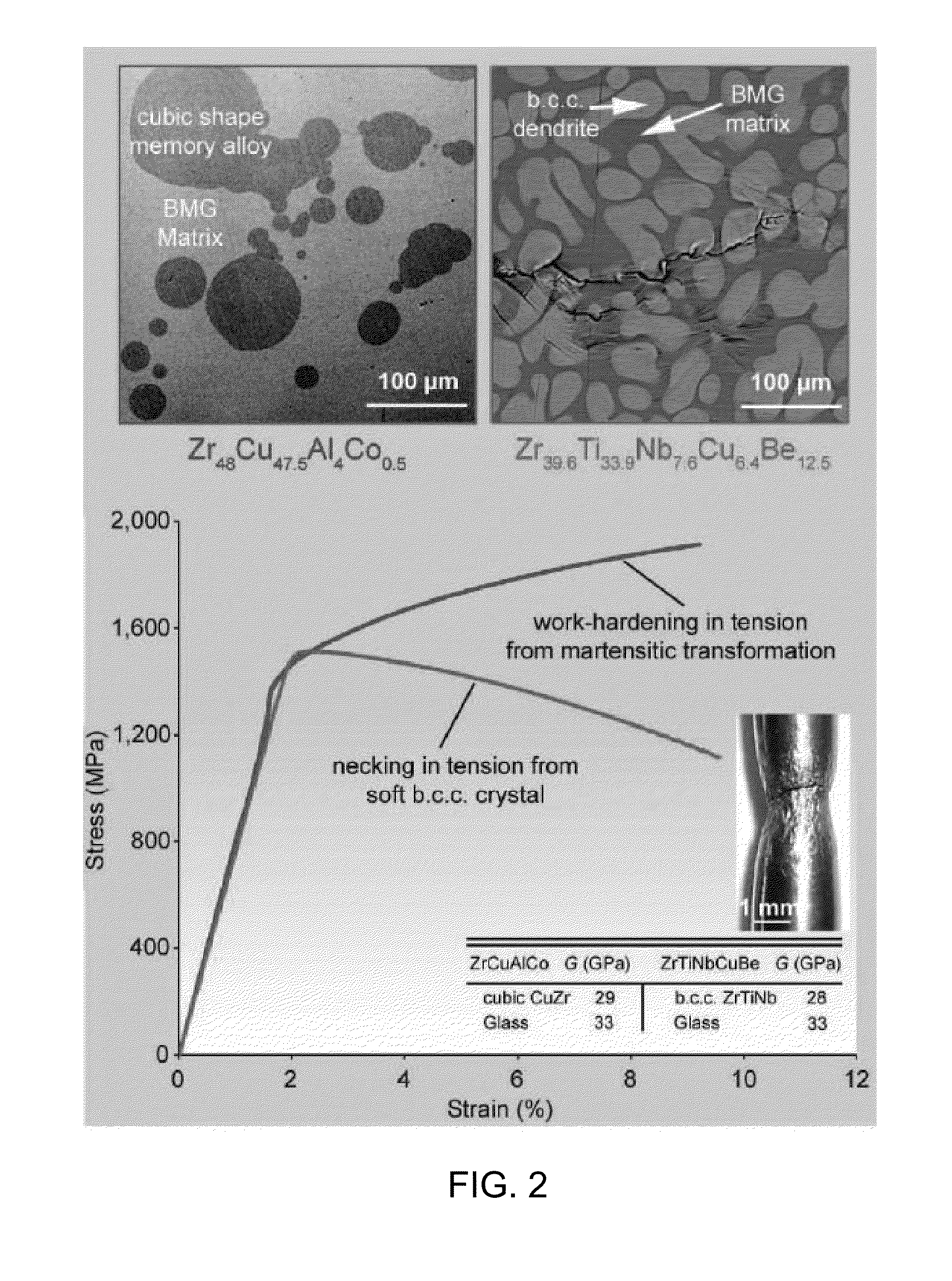

[0038]Turning now to the drawings, systems and methods for implementing bulk metallic glass matrix composites in the fabrication of objects are illustrated. In many embodiments, a bulk metallic glass matrix composite composition is formed into the shape of an object to be fabricated, and the composition is developed to include non-equilibrium inclusions that are softer than the surrounding matrix (e.g. as measured by shear modulus, elastic limit, or hardness). In a number of embodiments, the formed composition is heat treated to develop the inclusions. In several embodiments, the heat treating is localized to regions where it is desired that the object be especially robust.

[0039]Although bulk metallic glasses can possess a number of advantageous materials properties that might make them suitable materials from which to fabricate some structural components from, they might not have the requisite resistance to brittle fracture and / or ductility that can allow them to implemented in man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Composition | aaaaa | aaaaa |

| Equilibrium | aaaaa | aaaaa |

| Crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com