Multi-functional metal fabrication glove

a multi-functional, glove technology, applied in the field of knitting gloves, can solve the problems of high cost of cutting resistance, many users have multiple needs, and the design of gloves for such applications can be challenging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

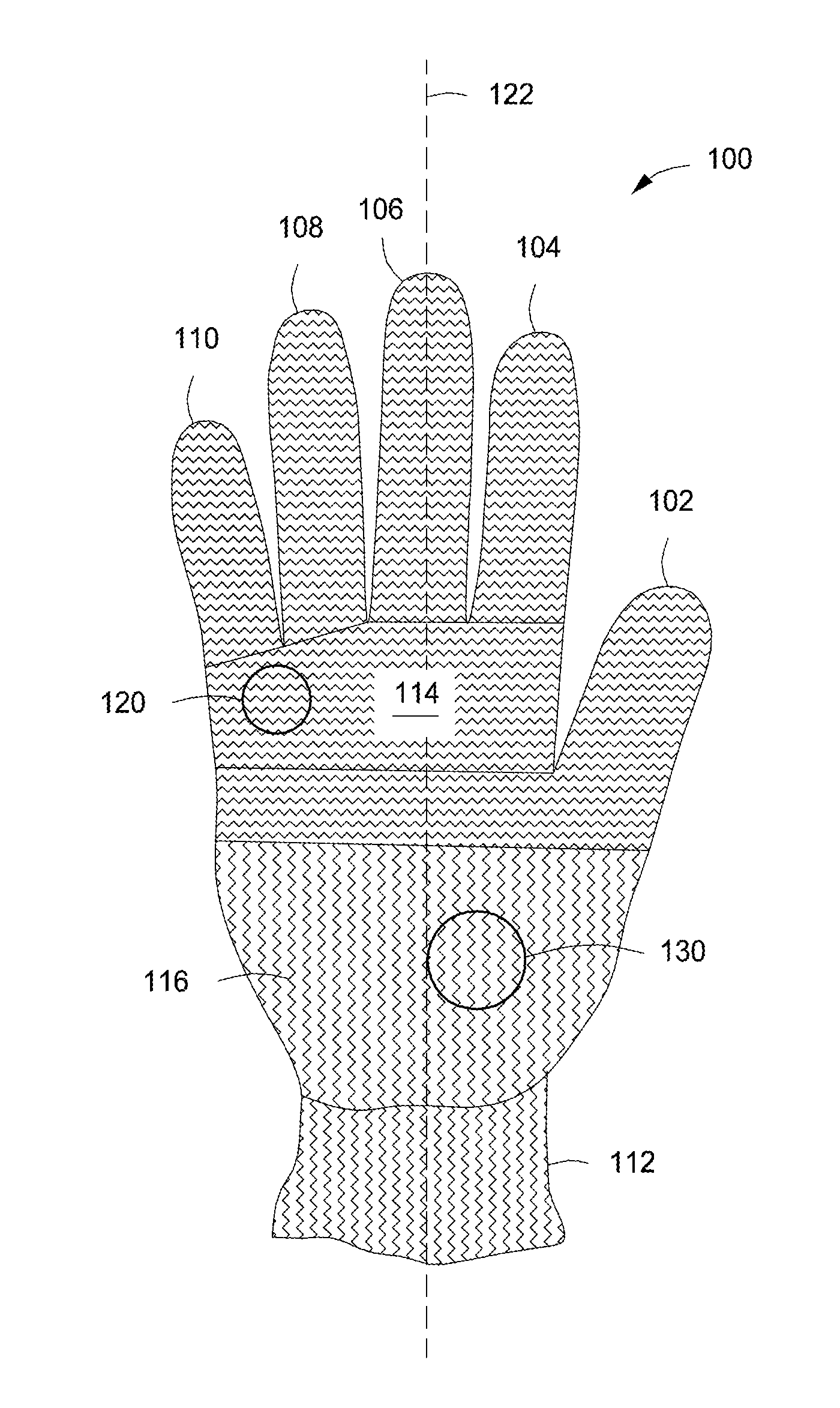

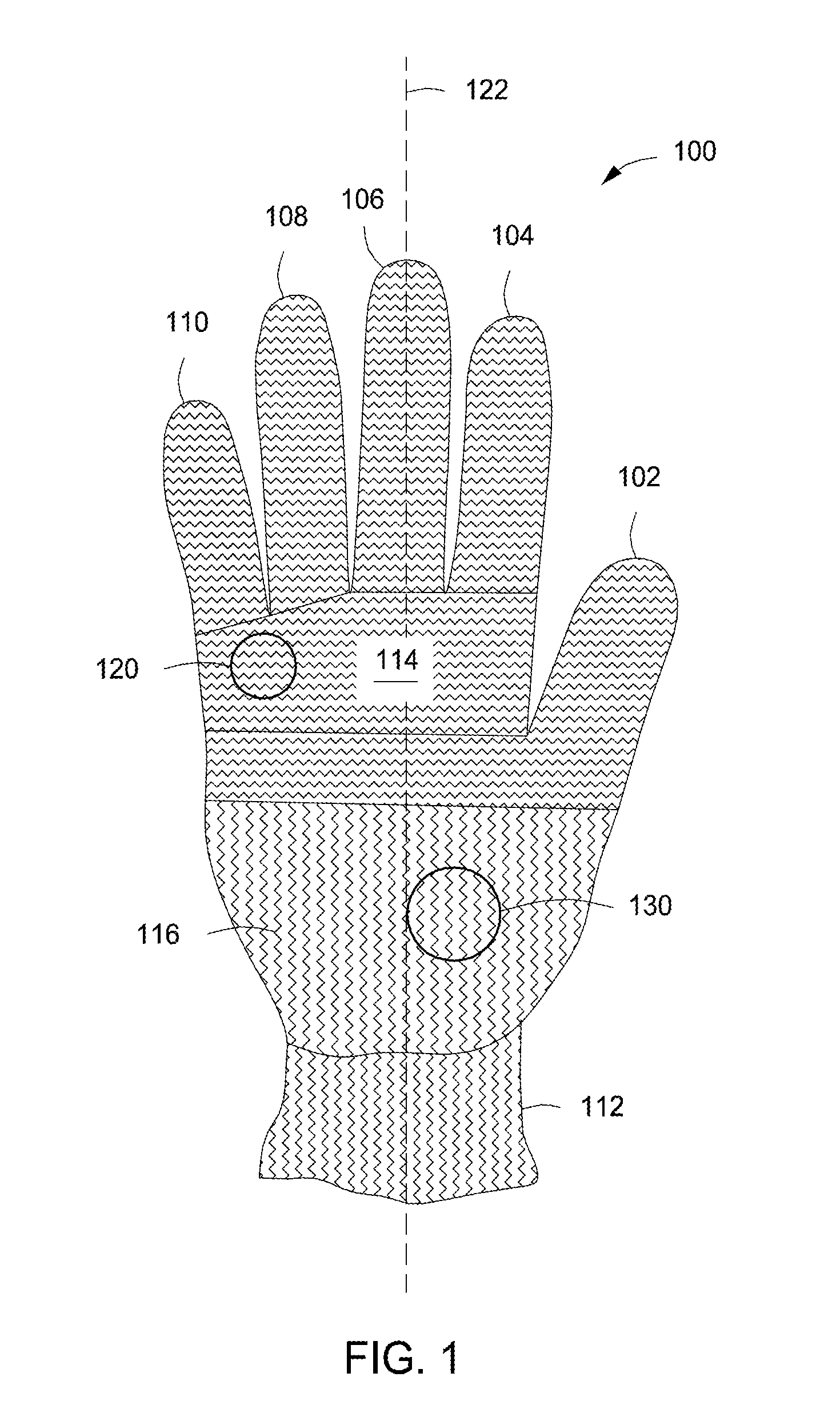

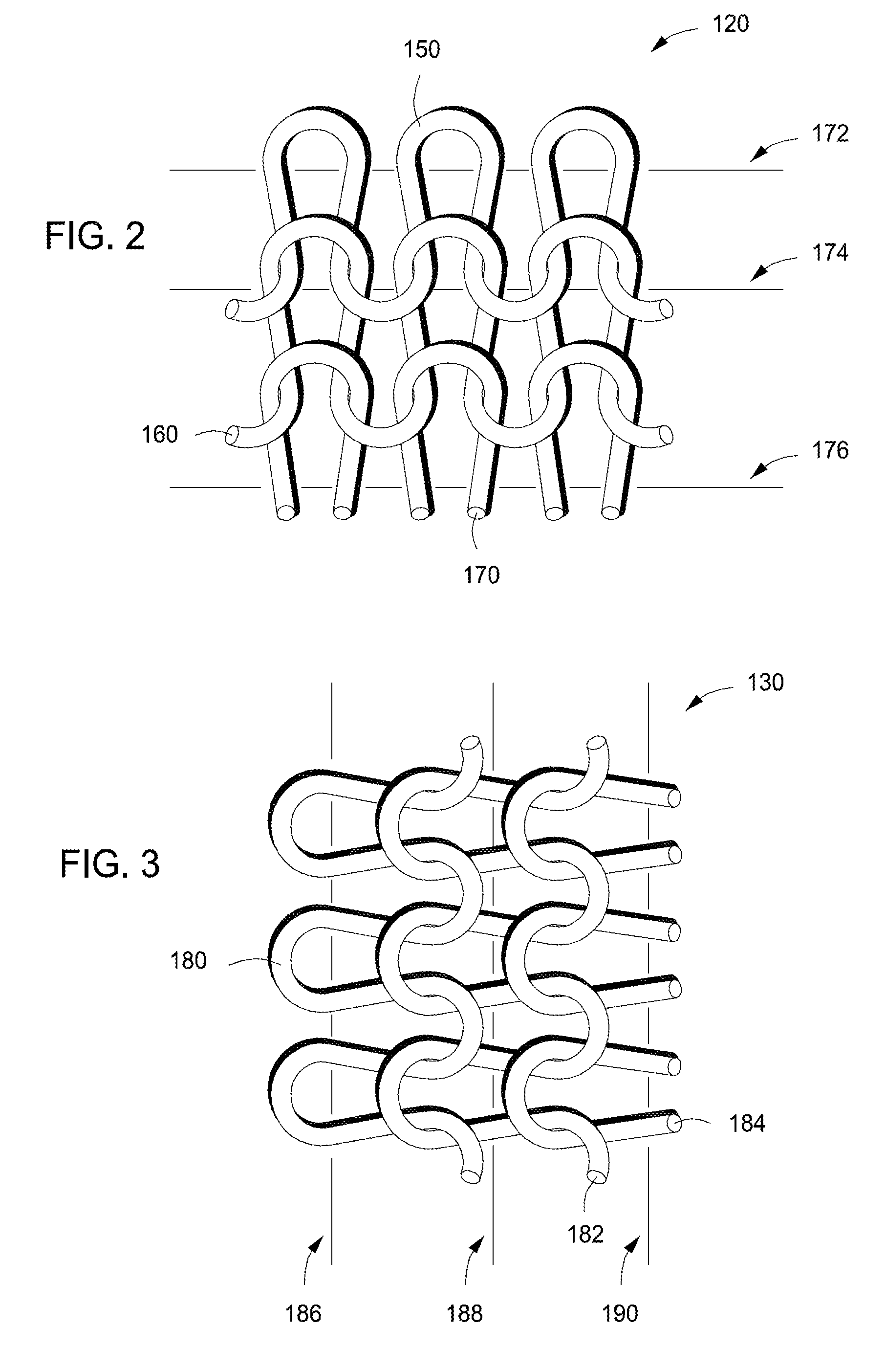

[0027]Embodiments of the present invention comprise a knitted liner having at least two different yarns. A first yarn exhibits a desired property, such as cut-resistance, and a second yarn exhibits a second desired property, for example, heat-resistance and is optionally knitted into different zones of the glove or liner than the first yarn. For example, a zone may be an upper palm, lower palm, upper backhand, lower backhand, fingers, thumb, or cuff zone. Knitted liners and gloves comprising knitted liners in accordance with embodiments of the invention may also specify different yarns for other properties, such as flame-resistance, moisture-control, chemical resistance, flexibility, impact-resistance, abrasion-resistance, and other desirable properties imparted by various yarns, blended yarns having several of the foregoing properties, and / or structures thereof.

[0028]Also, embodiments of the present invention comprise knitted liners and gloves that can be fabricated using vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com