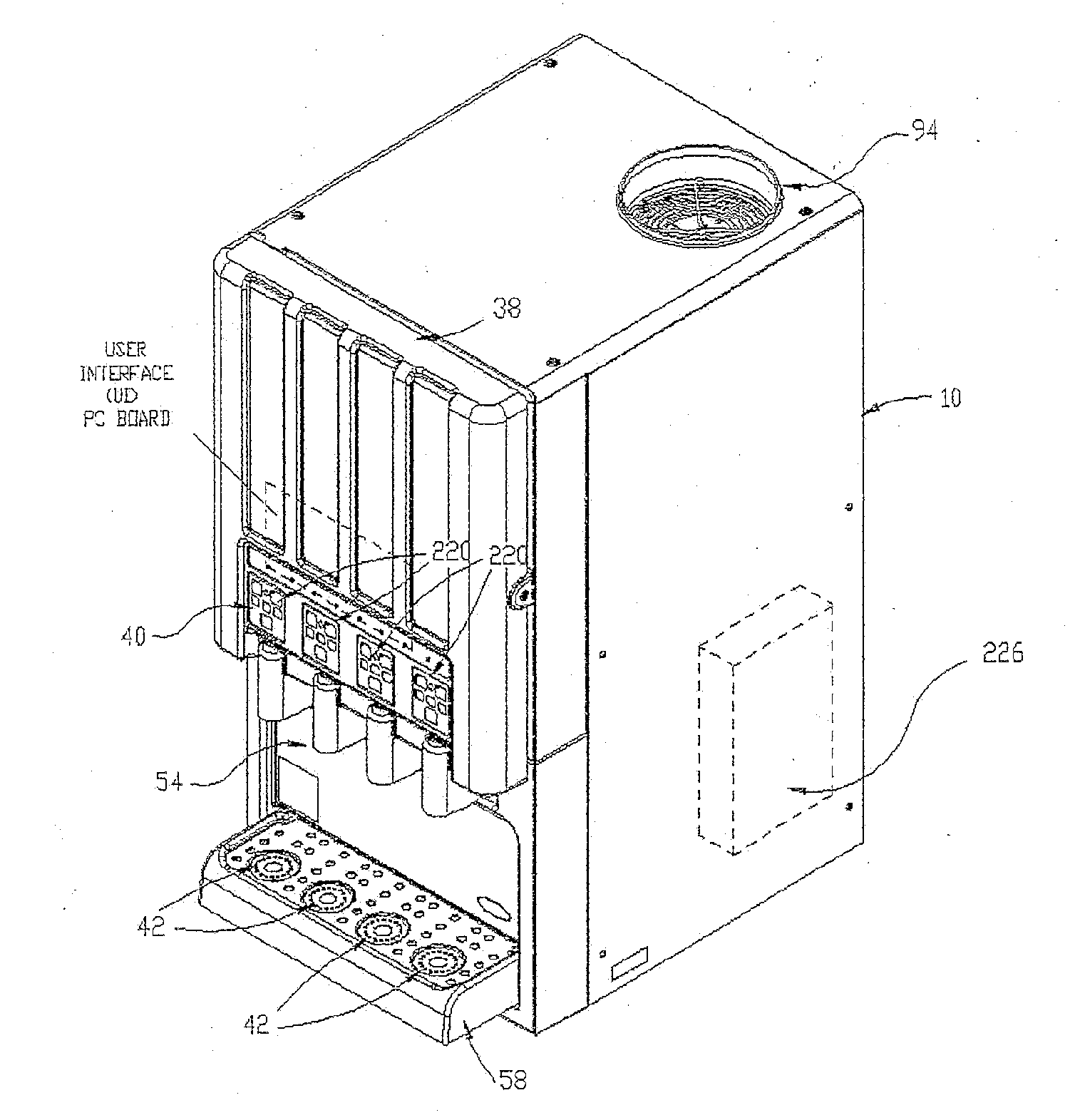

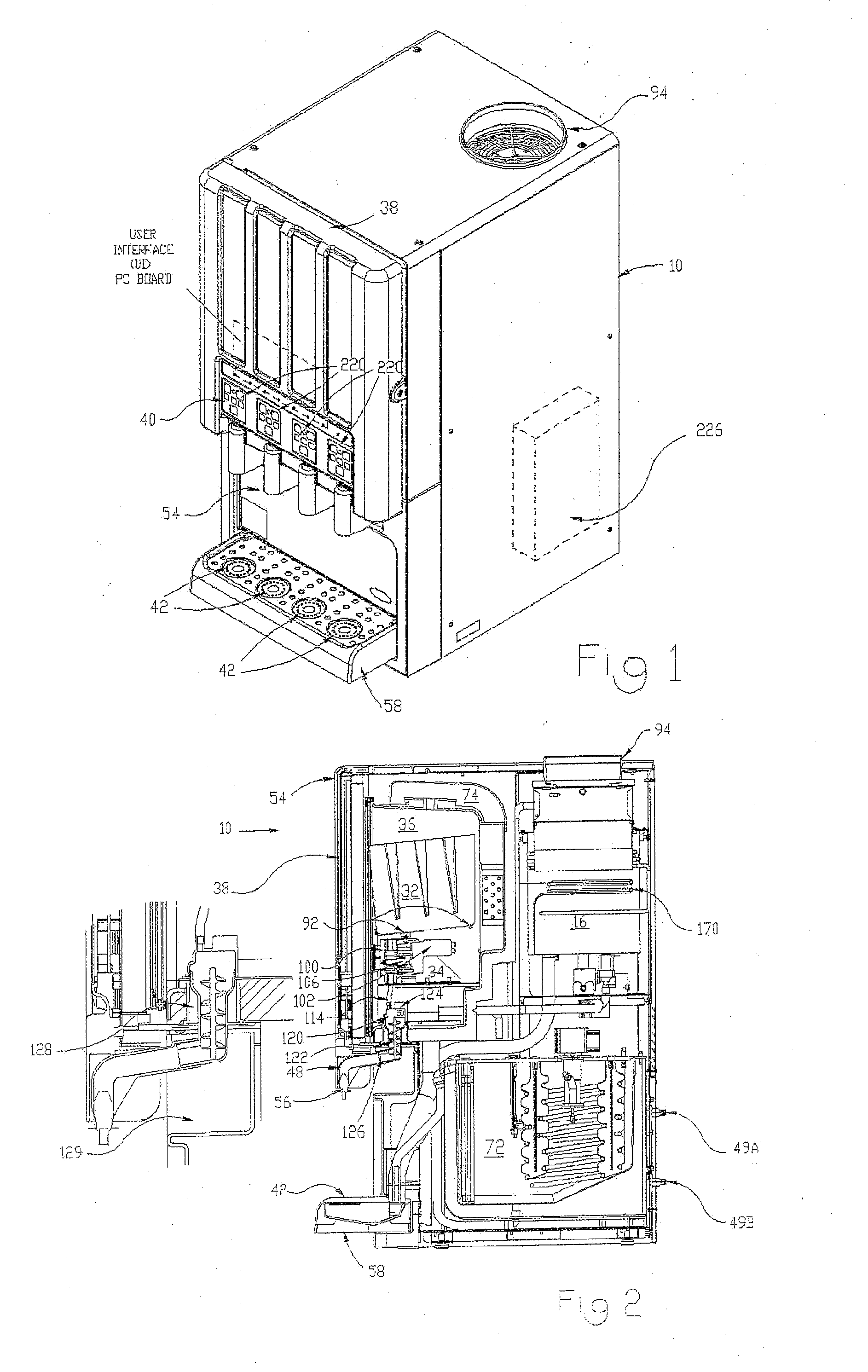

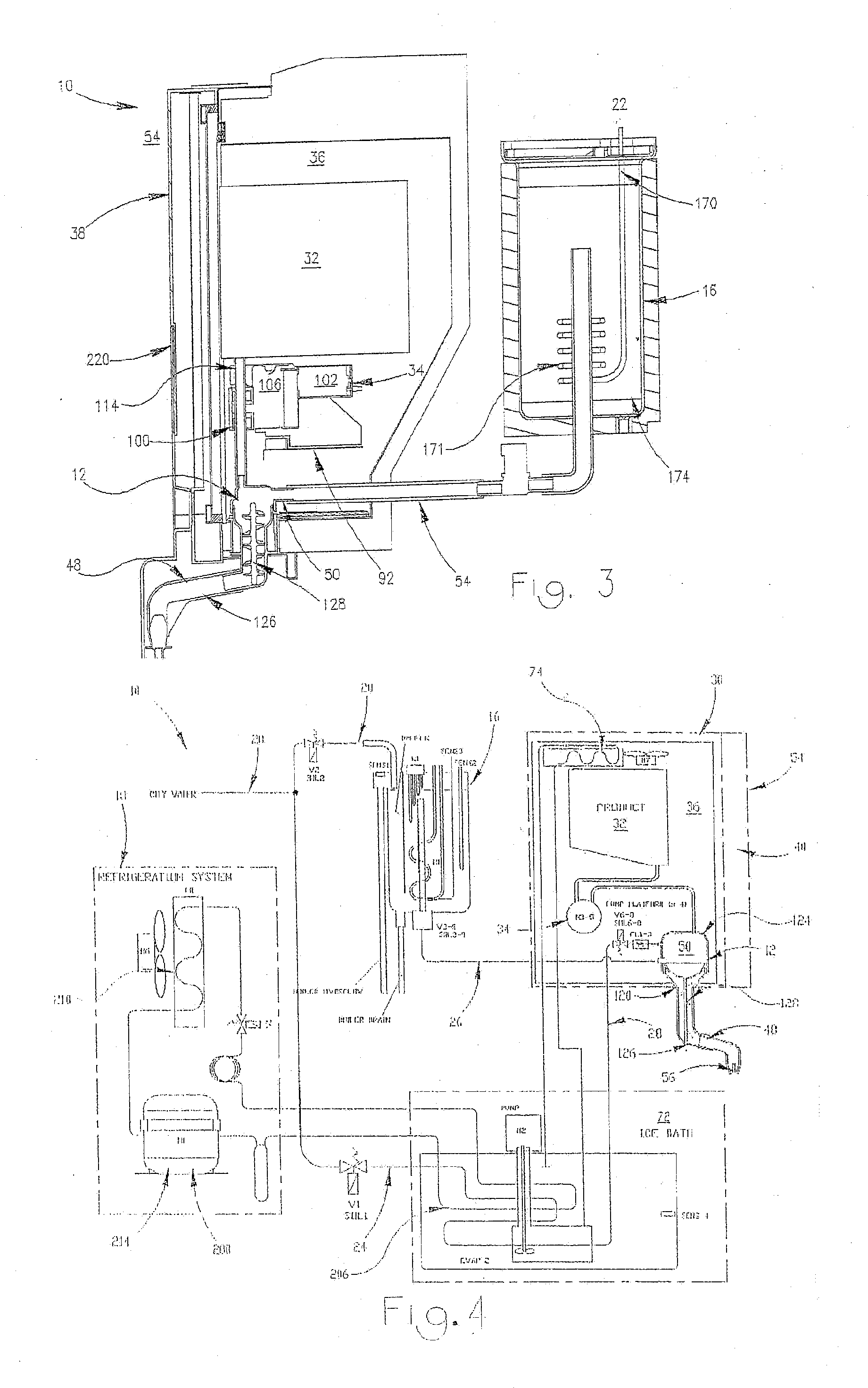

Hot/Cold Beverage Dispenser and Method

a beverage dispenser and hot/cold technology, applied in the field of hot/cold beverage dispensers and methods, can solve the problems of insufficient flavor and known to deliver hot or cold water, and achieve the effect of increasing the height of fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0093]1. Calculating Ratio for a 12 oz drink @ 3:1[0094]CD=Concentrate Dispensed (ounces)[0095]WD=Water Dispensed (ounces)[0096]W=3[0097]C=1[0098]V=End Volume

[0099]The calculation for the concentrate would be.

CD=C / (W+C)*V

CD=1 / (3+1)*12

CD=3 oz

[0100]The calculation for the water would be.

WD=W(W+C)*V

WD=3 / (3+1)*12

WD=9 oz

2. Flow rate per Water / Ratio Calculation[0101]DT=Dispense Time (seconds)[0102]FW=1.84 oz / sec

[0103]The calculation would be:

DT=WD / FW

DT=9 oz / 1.84 oz / sec

DT=4.89 sec

3. Flow rate per Ratio Concentrate Calculation[0104]CFS1=Desired Concentrate Flow rate (ounces per second)

[0105]The calculation would be:

CFS1=CD / DT

CFS1=3 oz / 4.89 sec

CFS1=0.61 oz / sec

4. Pump RPM vs Ratio Concentrate Calculation

[0106]Assuming a speed of 231 rpm[0107]CFS2=Actual Concentrate flow rate VS pump speed[0108]GBR=231 rpm[0109]GBS=Gear Box Speed (RPS) Revolutions per Second

Constants

[0110]T1=60 SECONDS (1 MINUTE)[0111]d1=0.159

Formulas:

[0112]

GBS=GBR / T1

GBS=231 / 60

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com