Concrete washout container with leakproof sealing lid

a technology of concrete washout containers and lids, which is applied in the direction of closures using stoppers, transportation and packaging, liquid handling, etc., can solve the problems of affecting storm drain systems, affecting the operation of storm drain systems, and a large amount of wet concrete continues to adhere to pour chutes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

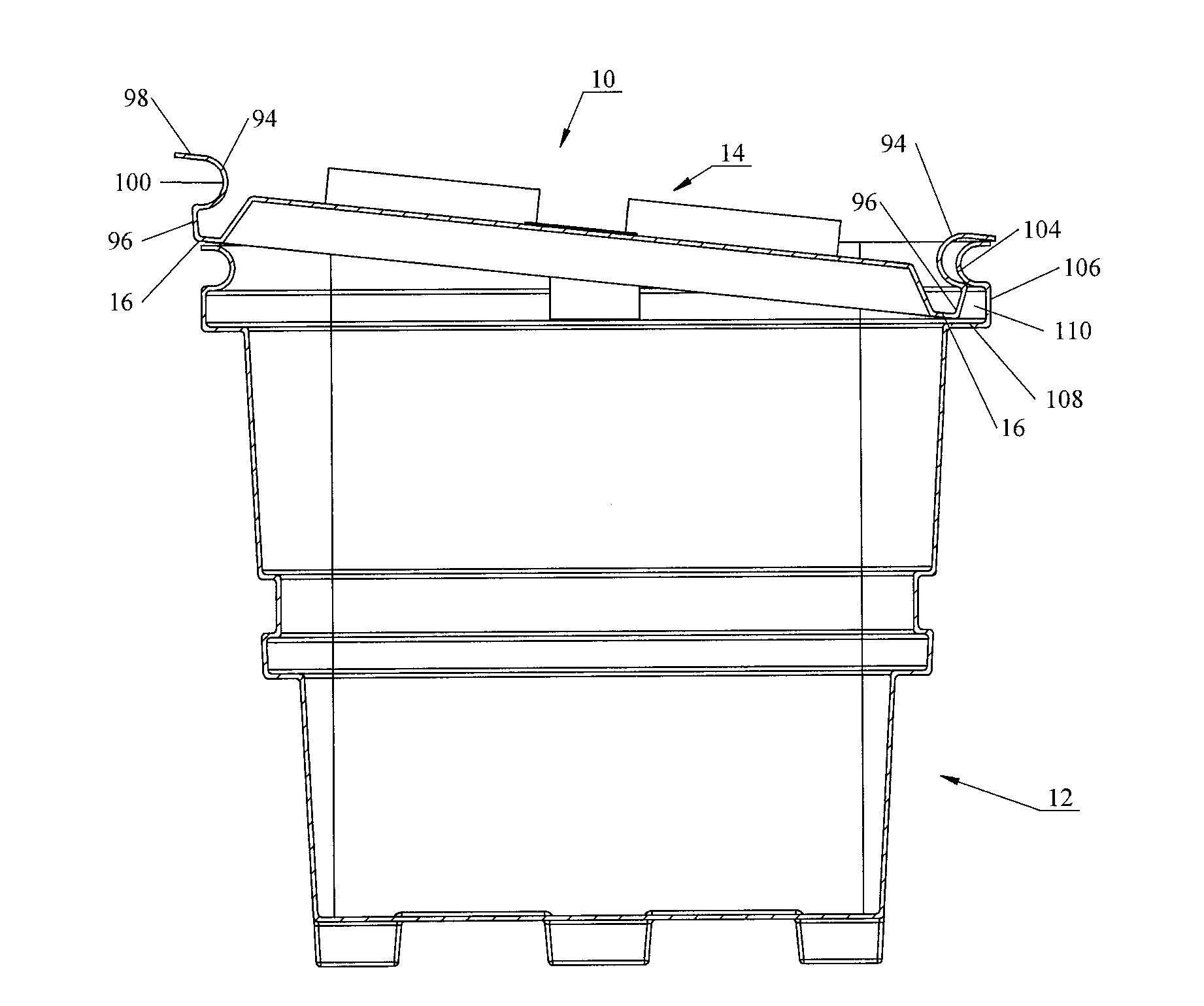

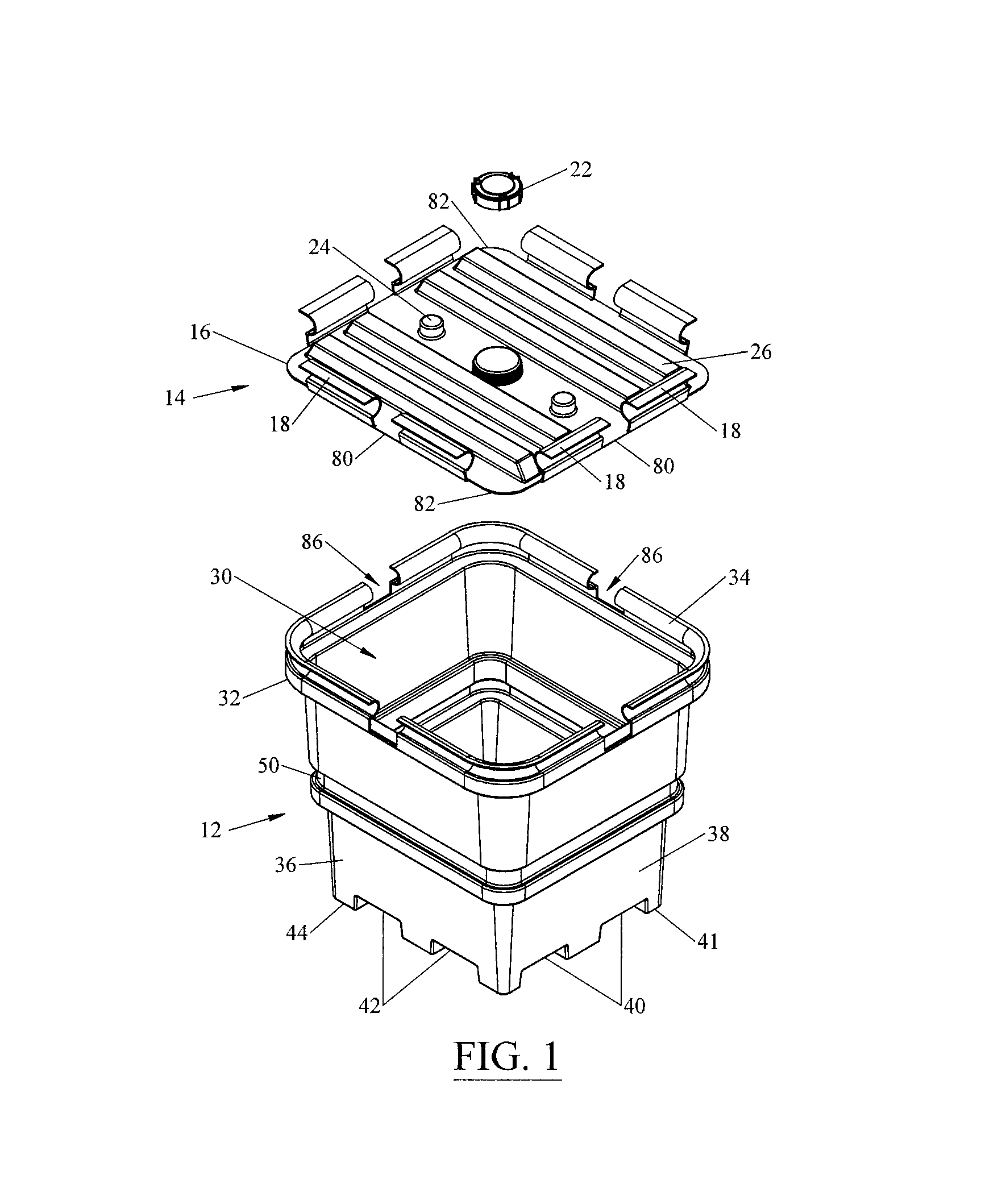

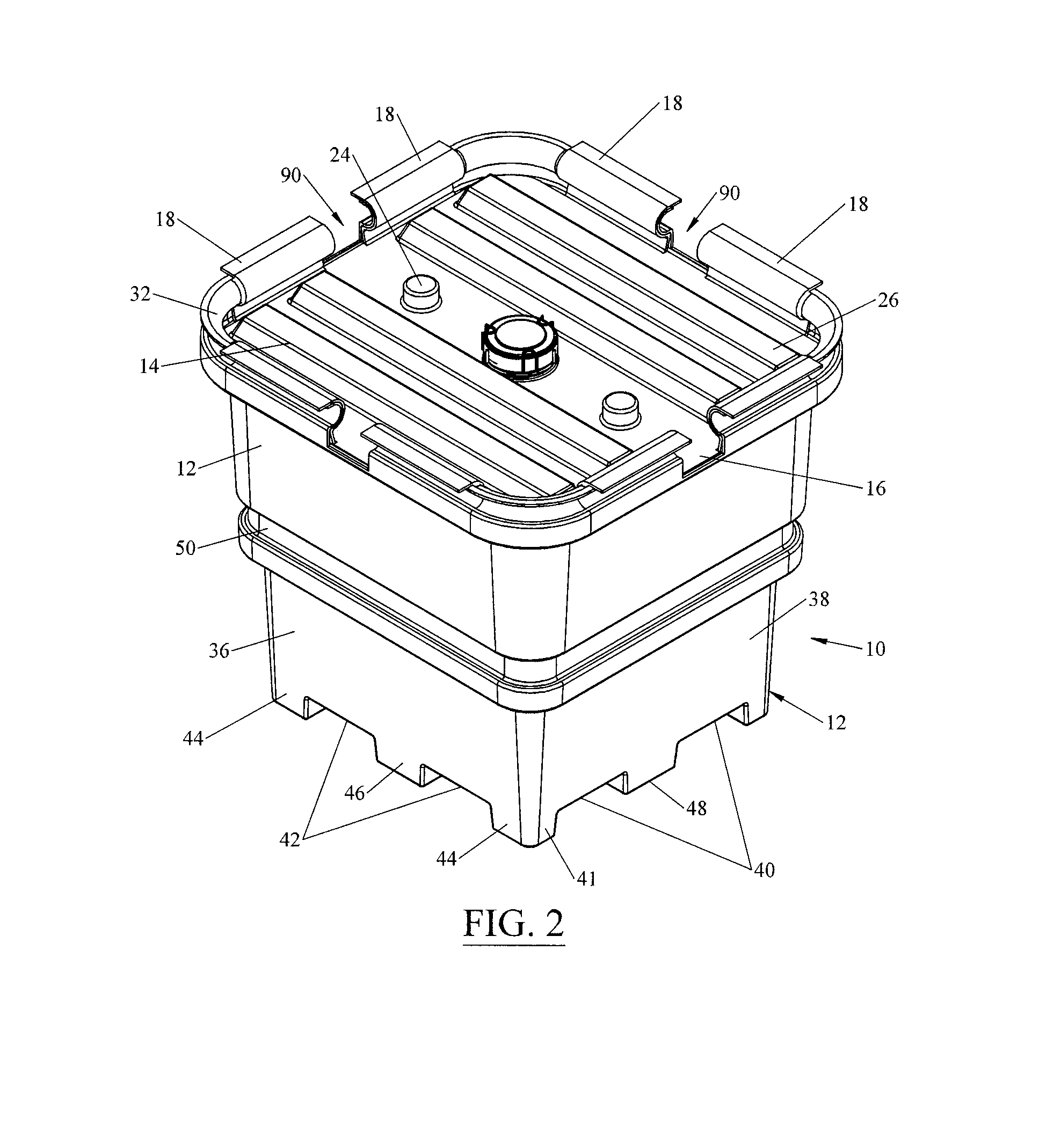

[0029]Turning first to FIGS. 1 to FIGS. 6A-D, there are shown various views of an exemplary embodiment of a concrete washout container with leakproof sealing lid 10. FIG. 1 is an isometric top front exploded view showing its bin portion 12 and lid portion 14. FIG. 2 is an assembled top front isometric view of the exemplary embodiment of the concrete washout container with leakproof sealing lid of FIG. 1. FIG. 3 and FIG. 4 are a front view and side view, respectively, of the exemplary embodiment of the concrete washout container with leakproof sealing lid 10 of FIG. 2. FIG. 5 is a top view thereof. FIGS. 6A-D show how the lid portion 14 engages with the bin portion 14. The lid portion 14 has a base 16 and lip structures 18 extending around the base 16. An opening 20 is preferably located on the lid portion 14, and a cap 22 is used to detachably cover the opening. The opening 20 can be a male or female threaded opening and is adapted to engage an opposite threaded cap 22. Other types ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com