Shoe and Manufacturing Method Therefor

a manufacturing method and technology for shoes, applied in the field of shoes, can solve problems such as difficulty in sewing reinforcement parts thereto, and achieve the effect of facilitating the production of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0085]Examples of the present invention will now be described with reference to the drawings.

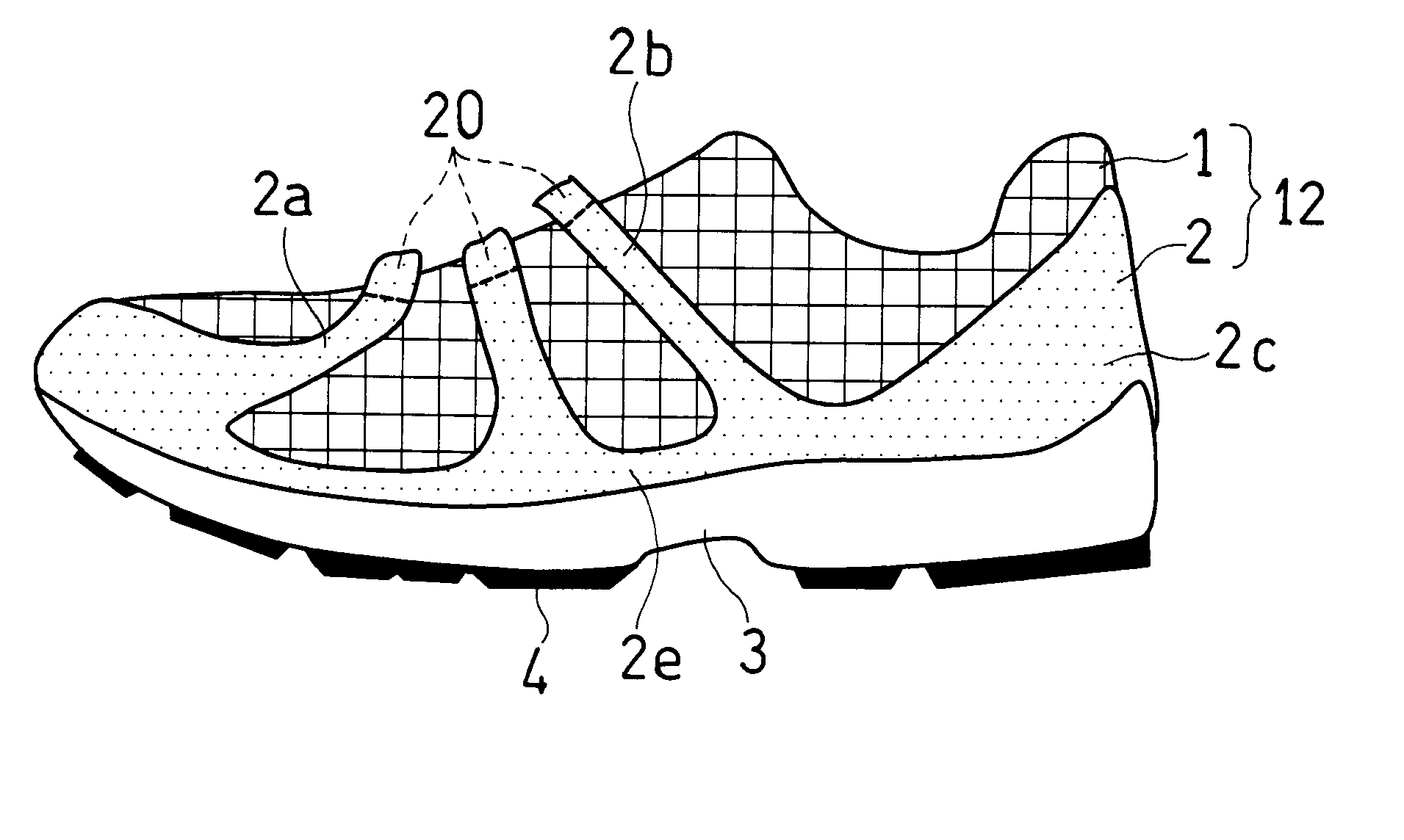

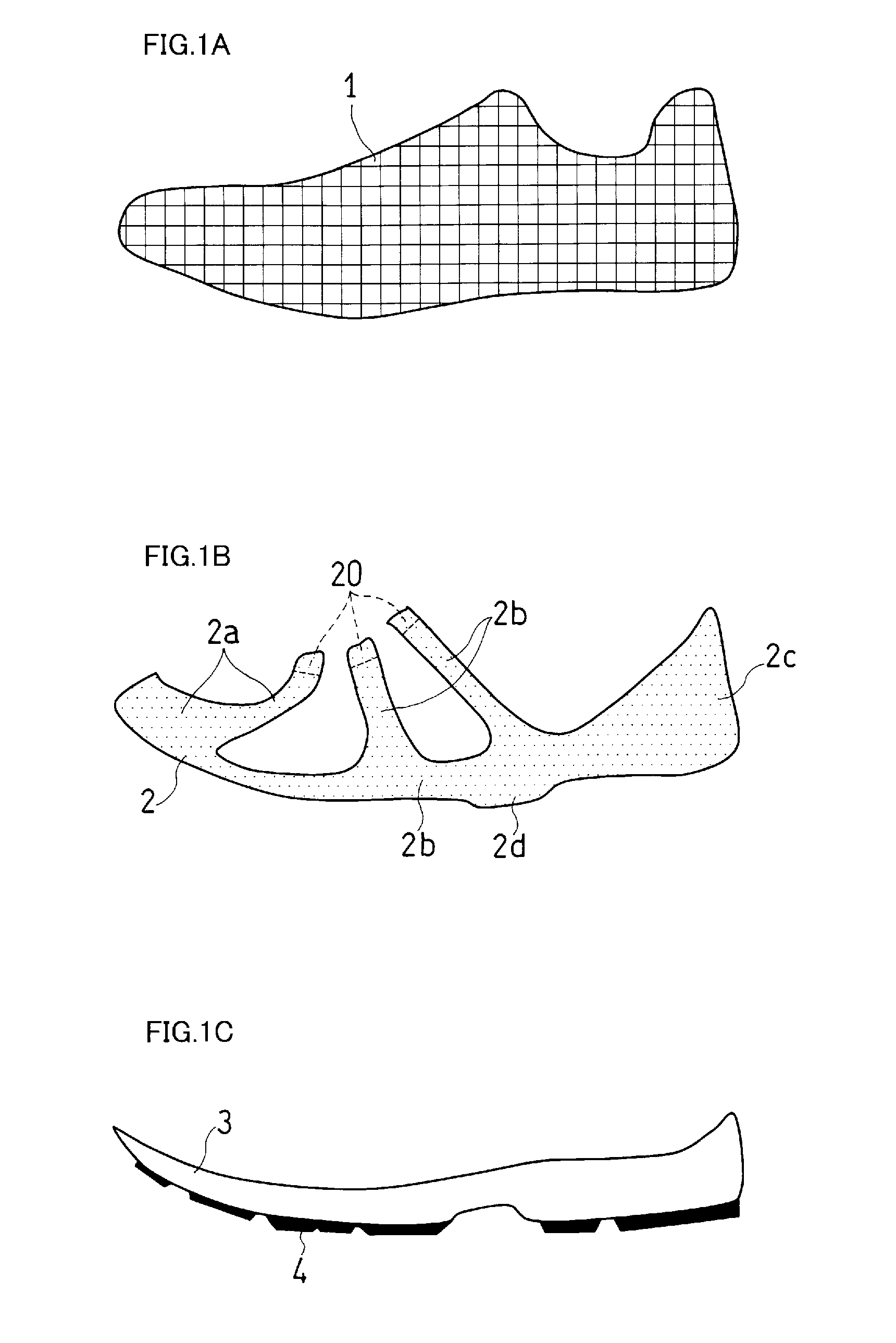

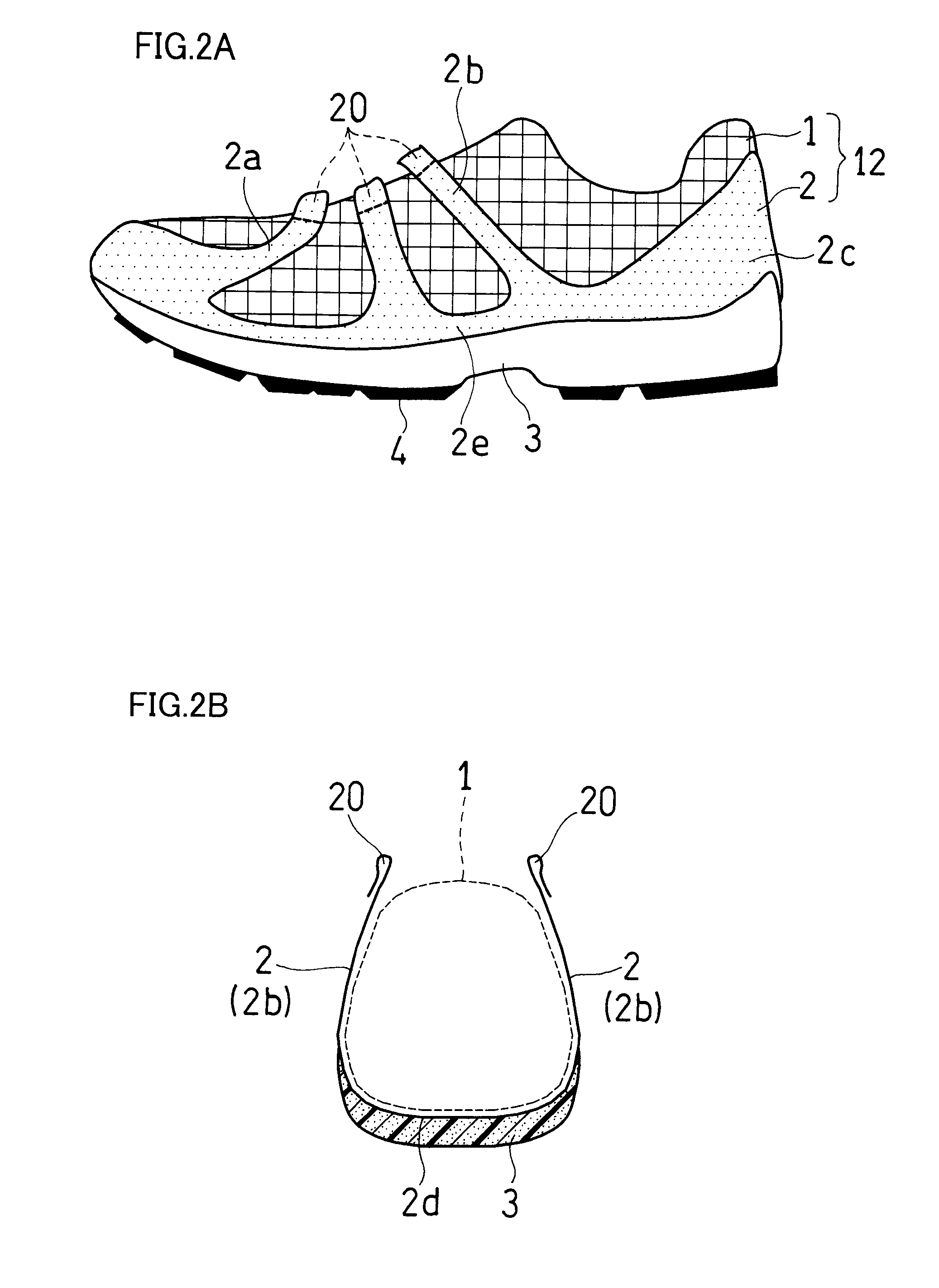

[0086]FIGS. 1A to 2A show Example 1.

[0087]As shown in FIGS. 1A to 1C, the shoe includes the base member 1, the reinforcement member 2, the midsole member 3, and an outsole 4. Note that in the drawings to be discussed below, the base member 1 is shown to be lattice-patterned, the reinforcement member 2 is shown to be dotted, and the outsole 4 is shown to be in solid black.

[0088]The base member 1 of FIG. 1A is formed in a sock shape by a knit fabric, a knit-like fabric and / or a woven fabric.

[0089]Herein, a knit fabric or a woven fabric can be produced by a well-known knitting machine or weaving machine, and can be formed by a synthetic resin fiber that shrinks by heat. An example of the base member 1 is disclosed in JP2004-105323A, the content of which is herein incorporated by reference in its entirety.

[0090]For example, the base member 1 may be obtained by weaving a member into a sock shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com