Method and apparatus for determining stiffness of a roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

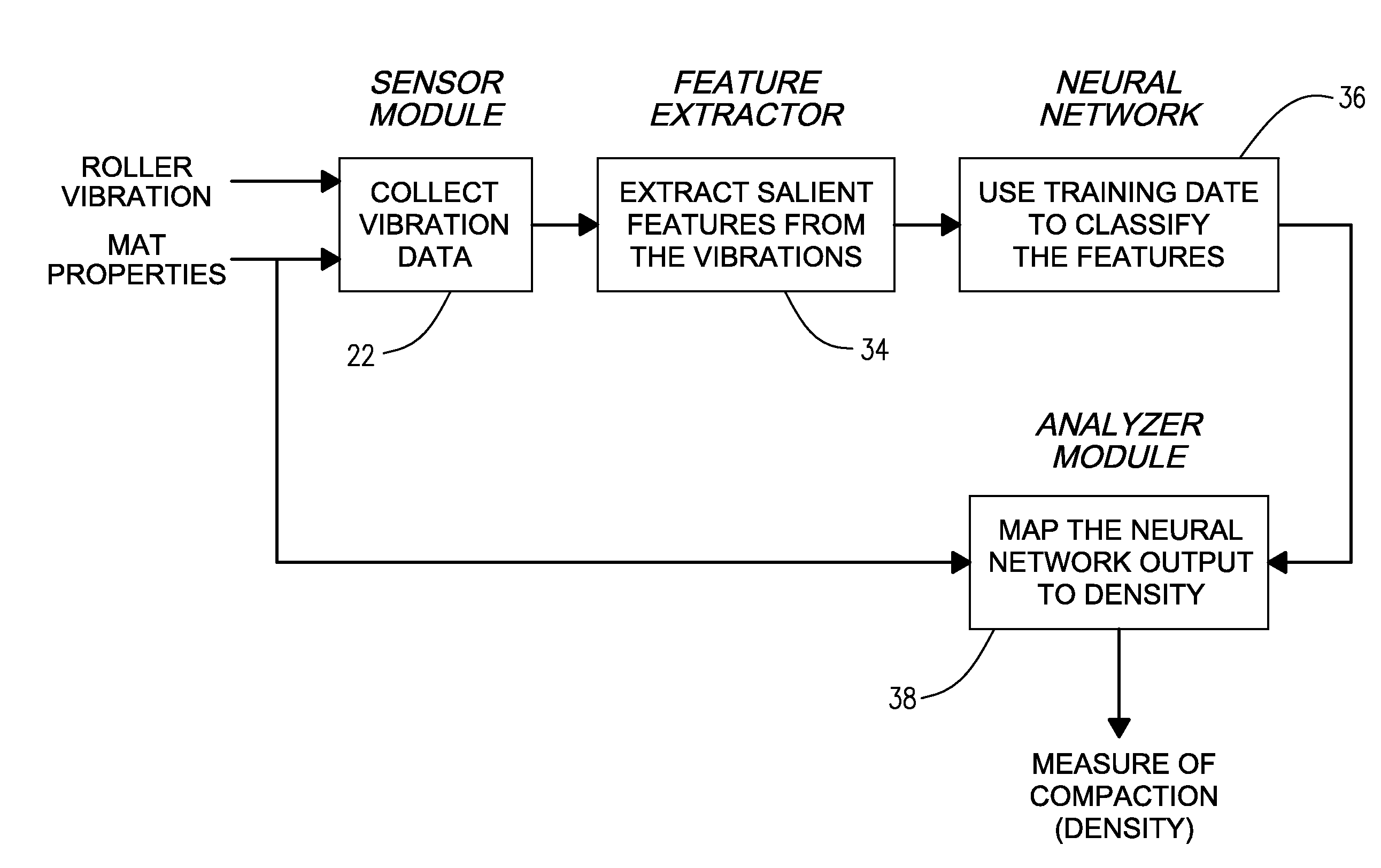

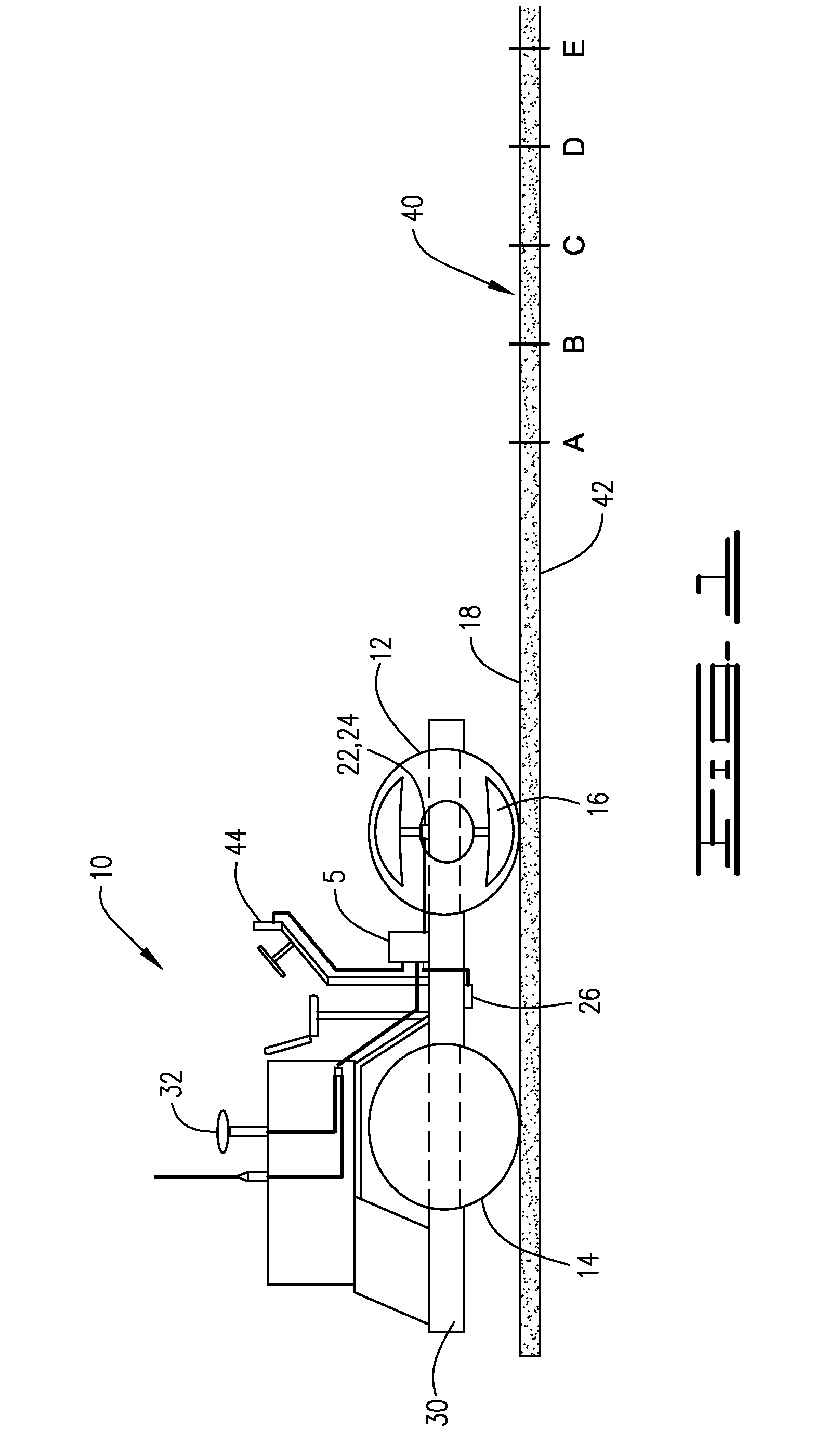

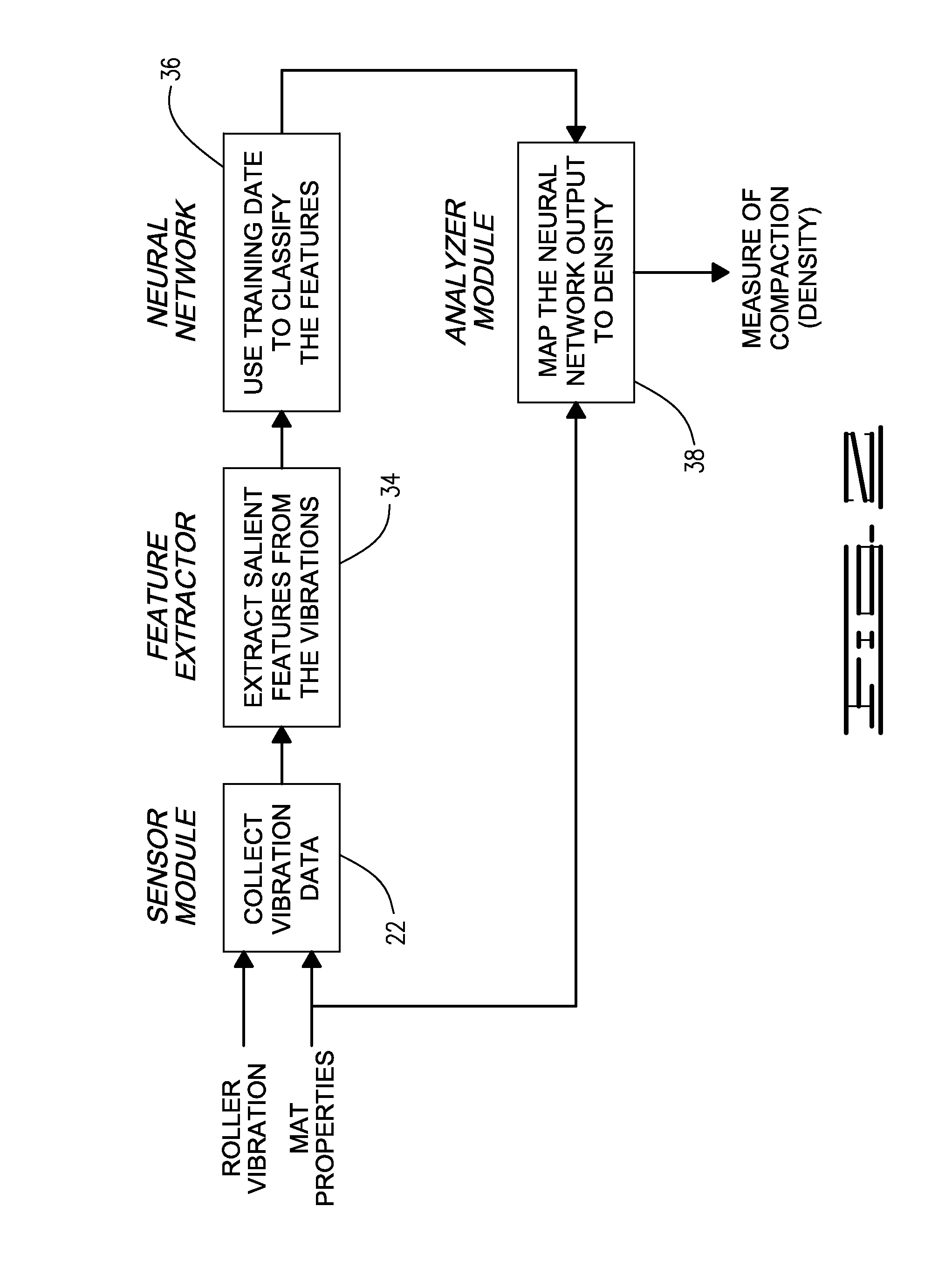

[0014]The current disclosure is directed to methods and apparatus for compacting a roadway, and for using, and calibrating an Intelligent Asphalt Compaction Analyzer (IACA). The current disclosure is likewise directed to a method of determining the dynamic modulus of a roadway, which is a measure of the stiffness of the roadway.

[0015]FIG. 1 schematically shows the IACA 5, a device that can measure the density of an asphalt pavement continuously in real time, over the entire length of the pavement during its construction. Quality control techniques currently used in the field involve the measurement of density at several locations on the completed pavement or the extraction of roadway cores. These methods are usually time-consuming and do not reveal the overall quality of the construction. Furthermore, any compaction issues that are identified cannot be easily remedied after the asphalt mat has cooled down.

[0016]In recent years, several Intelligent Compaction (IC) technologies have b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com